Researchers at the Netherlands’ Delft University of Technology have succeeded in printing silicon on a substrate. Previous work in printing circuitry has focused on organic and metal-oxide inks, but these materials have a lower performance than silicon.

The team used polysilicon (poly-Si) in the work, producing it directly onto a substrate using liquid silicon ink, with a single laser pulse. The new method bypasses the thermal annealing that was previously used to print silicon ink, which required temperatures up to 350° – too hot for many flexible substrates.

“We coated liquid polysilane directly on paper by doctor-blading, or skimming it by a blade directly in an oxygen-free environment”, said Ryoichi Ishihara, who led the work. “Then we annealed the layer with an excimer-laser [a conventional tool used for manufacturing LTPS smartphone displays]”.

The laser blast lasted for just a few nanoseconds. In conductivity testing, the team found that the new printed transistors had mobilities as high as those in conventional poly-Si conductors.

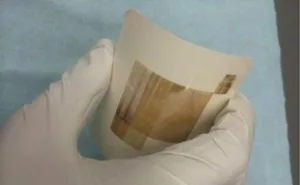

The most immediate application of the technology is in wearable electronics, the team has said. The process can be used to produce fast, low-power and flexible transistors at a low cost.