Even though SID Display Week started this week, I could not help myself from attending a new conference last week with a heavy focus on quantum dot technologies. Since I also dabble in technology areas outside of displays, I was very interested to attend TechBlick’s “Quantum Dots – material innovations and commercial applications” conference.

Compared to most other remote conferences, this one promised live talks and discussion, an attractive value proposition compared to all pre-recorded talks. There were a number of familiar faces, and some new ones as well. I love to see that the community of QD companies continues to grow (along with the possible commercial applications)!

Perovskite applications are expanding

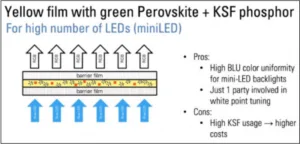

Avantama claims to be the very first supplier to pass panel maker qualifications using perovskite-based QD films. When paired with KSF phosphor (red) they claim to be able to achieve >90% of REC 2020 and >99% of DCI-P3 with high brightness. They envision two options for how to use these two materials together:

- Red KSF on blue LED (magenta LED) and green perovskite in film.

- KSF and perovskite QDs in a film together with blue LED backlight.

Interestingly, they focused on a mobile market where mini-LEDs could be used with a KSF/perovskite film solution for color conversion. I find it very interesting that they are choosing to compete directly with current QD film technology by offering a green perovskite/red KSF combination solution in the form of a film.

Avantama shared their vision of using perovskites along with KSF in the same film to generate excellent color gamut from a product that would compete directly with current InP or CdSe QD films.

Avantama shared their vision of using perovskites along with KSF in the same film to generate excellent color gamut from a product that would compete directly with current InP or CdSe QD films.

Helio Display Materials is another company focused on perovskites, but with a focus on red (most others are focused on green for displays). They claim to have both green and red perovskite solutions providing a color gamut of 92% of REC 2020 when paired with a blue LED. Apparently, they have made some good progress with improving the stability of red perovskite materials. Since the red perovskite materials (FWHM peak width = 31 nm) are up against the likes of KSF phosphor and InP QDs, there are still significant hurdles to reach commercial status. For those who are concerned about heavy metals, my understanding is that these materials still contain lead.

Helio articulated quite well one of the lesser-known advantages of perovskites that I feel is worth sharing.

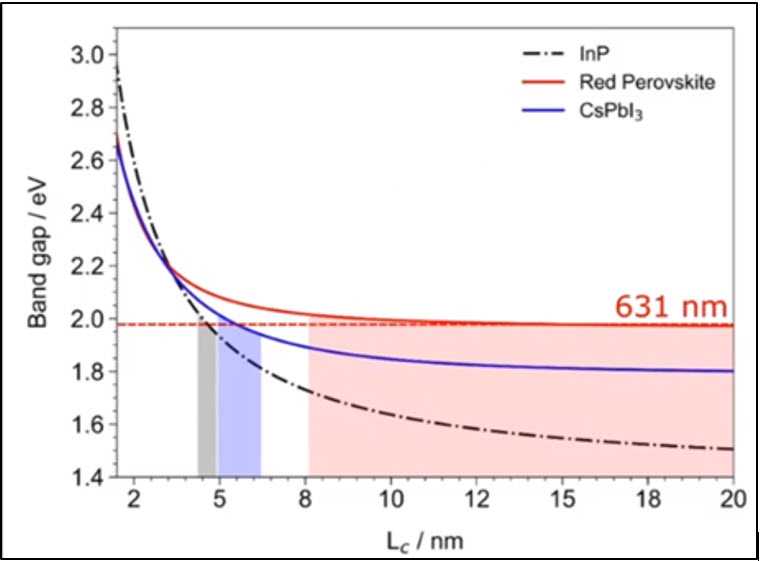

Perovskites don’t have to be quantum dots to perform well. In fact, due to their unique properties, they can make for excellent emitters at sizes beyond “quantum confinement”. This has the unique advantage of being more tolerant of size, meaning that at a size of 12nm, 15nm, or 20nm, they will all emit the same color (if they are the same composition that is).

As you may know, QDs are tunable based on their size (when in the very small size regime) but this brings about challenges in manufacturing as all QDs must be tightly controlled to be the exactly the same diameter. With perovskites this manufacturing challenge goes away, assuming one chooses to make them large enough to be size-independent bandgap (aka emission wavelength).

While all QD materials would exhibit this size-independent bandgap at large sizes, it is not a suitable way to make most materials. For example when InP gets to large sizes, the bandgap is no longer useful for displays (1.5 eV= 826 nm in the graphic below) and in addition the efficiency (PLQY) of the material will decrease.

Graphic from Helio showing that the bandgap of perovskites are size-independent (horizontal red/blue lines) once they reach a certain size of ~12 nm. This allows for greater tolerance in manufacturing.

Graphic from Helio showing that the bandgap of perovskites are size-independent (horizontal red/blue lines) once they reach a certain size of ~12 nm. This allows for greater tolerance in manufacturing.

BrightComSol, a newcomer to the perovskite scene, appears to be focusing their efforts on perovskites as x-ray scintillators. Instead of exciting with blue photons, x-rays can also be used to excite QDs as well, with the same bright green emission. Apparently, perovskite-based films can be far cheaper than the current phosphor scintillator technology.

Quantum Solutions, which focuses on both perovskite and lead sulfide QD production, shared the excitement of BrightComSol for the new application in x-ray (and UV) conversion. Interestingly, their other offerings include PbS QDs which are appropriate for the next category – photodetectors.

Photodetectors gaining momentum

Embrion, SWIR Vision Systems, and IMEC all presented on their QD-enabled infrared imaging technology. I must say I am constantly impressed with the progress I see in the application of QD infrared photodetectors. This is a field in which I remain actively interested, and one that I think has great potential to be the next big market where QDs can make an impact.

Big markets include autonomous vehicle sensors and smartphone cameras (think facial recognition), although for now it seems to be gaining traction in industrial automation. While these sensors cannot compete with commercial InGaAs detector sensitivity/efficiency, they excel in resolution, field of view, and cost. Who knows, in a few years maybe we will have devices that contain QDs in the display AND the camera?

![]() SEM image of IMEC’s 5 um pixels showing a buried QD layer, and a cartoon cutaway of SWIR Vision Systems QD sensor stack.

SEM image of IMEC’s 5 um pixels showing a buried QD layer, and a cartoon cutaway of SWIR Vision Systems QD sensor stack.

Other materials innovations continue

Qustom Dot described their InP materials created by a novel synthetic method, leveraging precursor selection to tune color. With a focus on on-chip, they certainly have their work cut out, as I am not familiar with an example of a non-Cd QD that exhibits sufficient stability for on-chip use.

With a focus on blue QDs, QNA is banking on the fact that nearly all displays and lighting technology today rely on blue photons. While the peak width looks very attractive (FWHM <20 nm) time will tell if these materials are good enough for displays.

UbiQD showed that QDs can be used to shift the color of sunlight to benefit plant growth, increasing crop yields by >10% in many pilot studies. It appears they are gaining traction in the cannabis industry, which I would imagine provides an excellent ROI to the growers, along with farmers growing other high-value crops. It’s also fun to imagine basically the same QD film that is in a TV being implemented across an entire greenhouse (with different QDs of course).

In summary, this was an excellent gathering of companies at TechBlick that we should all be keeping an eye on. The technical progress in quantum dot world never ceases to amaze me. (PP)