One of my favourite sayings is that “There’s no Moore’s Law for optics.” We get used to miraculous improvements in electronics systems, and it can be tempting to think that other technologies might improve just as fast. On the face of it, the saying is true, but optics. It’s an intriguing area.

Professor Mohsen Rahmani is professor in Nanotechnology, Optics and Photonics at the Nottingham Trent University in the UK and the UK chapter of the SID arranged for him to talk about the uses of nanoparticles in optics, so I listened in. The talk will be made available via the SID for those that want a deeper dive. The professor, fortunately, was good at making the concepts used accessible to non-specialists like me.

Lenses and Mirrors are Old Technology

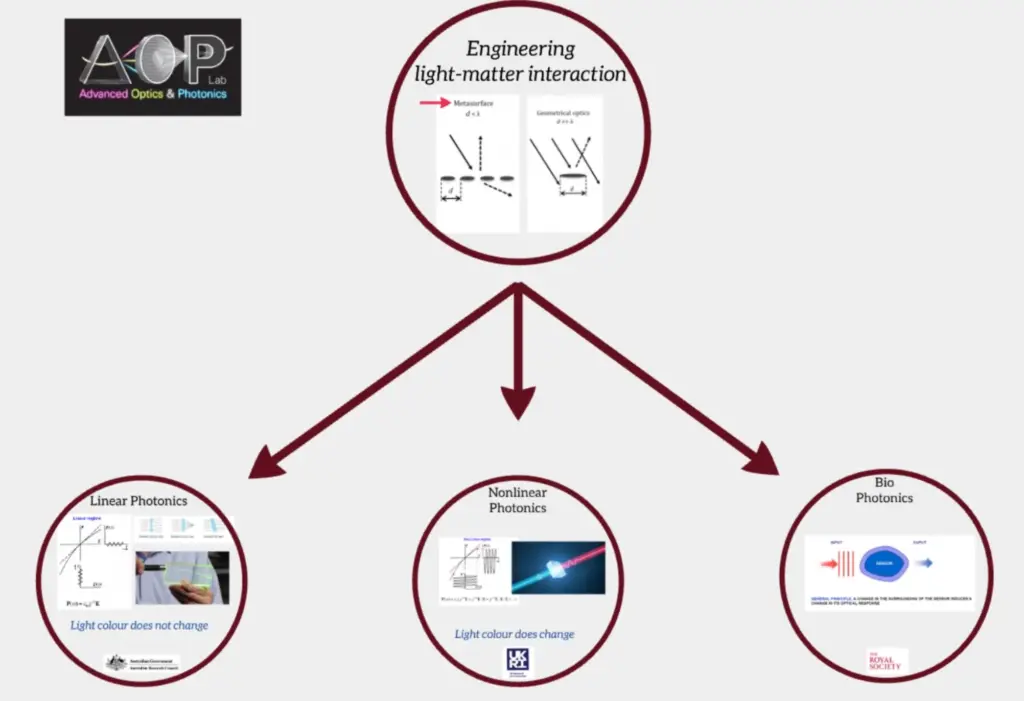

Rahmani started by highlighting that lenses and mirrors have basically been made using the same concepts for several hundred years. However, nanoparticles can be used to achieve the same effects as traditional glass surfaces by putting nanoparticles, smaller than the wavelength of light, on surfaces to have the same influence on the light. He divided the changes into three areas.

- Linear photonics (basically where just the direction or amplitude changes, but color doesn’t)

- Non-linear photonics (where the color does change)]

- Bio photonics

I’m focusing on the first area where there are direct display applications, but the other two areas also have important and intriguing applications.

Linear Photonics

In linear photonics, the particles are put on a surface which then becomes a metasurface and by using different materials you can create different effects as there is different resonance between the light and the materials. These surfaces can be used to make metalenses without the bulk or weight of traditional lenses and Rahmani said that there is ‘lots of work’ going on in this area (and Display Daily has reported on this in the past – check the metasurfaces tag). His group has worked with automotive companies, for example, to create systems for checking driver distraction that are much smaller and with better performance than lenses, using metalenses that are as thin as 1/20th of a human hair.

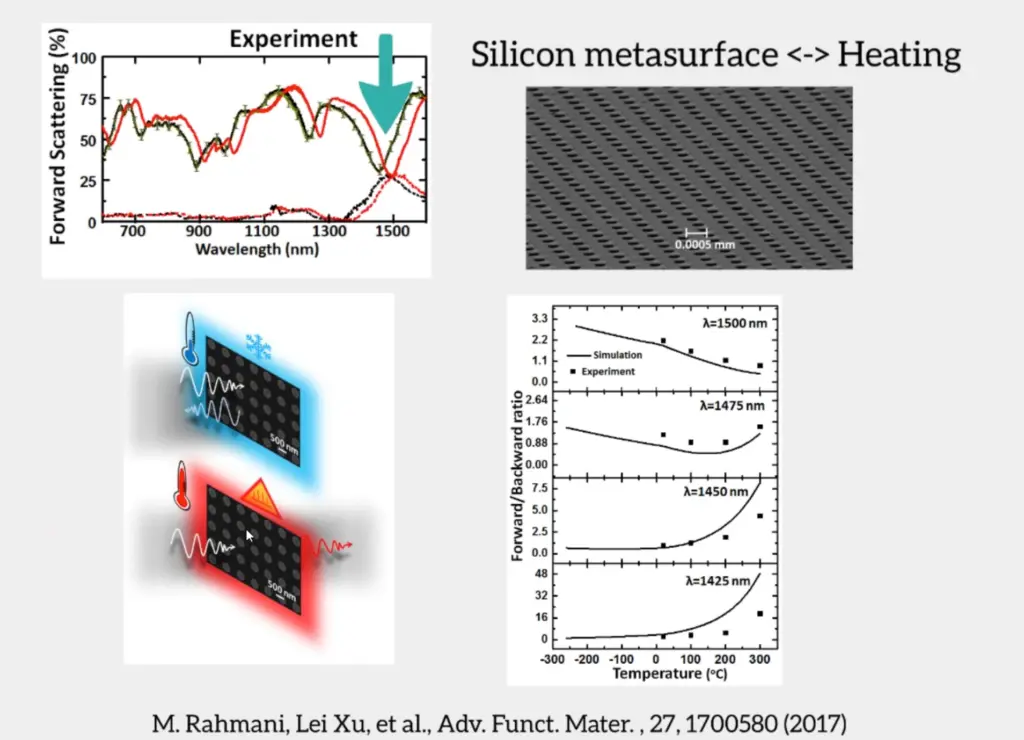

However, his group also discovered that you can change the properties of the metasurfaces using temperature (or you can also use phase changes or by applying strain but they both have significant disadvantages). You can use the heat to change the refractive index of the materials to make the surface more reflective (like a mirror) or transmissive (like a window). The light is not absorbed by the silicon used in his tests, but was either reflected or transmitted.

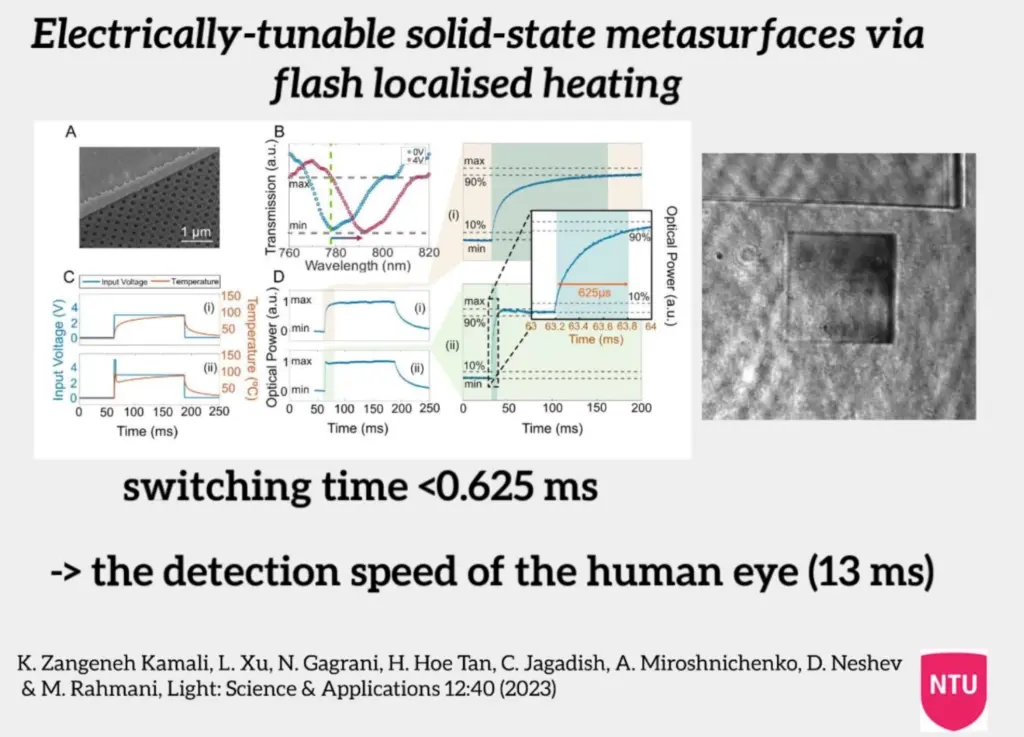

Initially, the change was too slow to be useful for a pixel, but by using patterned ITO above the surface and passing a current (at about 4V) the heating could be speeded up and using what he called ‘Flash’ heating, but similar to overdrive in an LCD pixel, the switching time (from 10% to 90%) could be reduced to 0.625ms. That’s fast enough that you can flash the pixel, but fool the eye into seeing a solid level of brightness. Given that the device could be as thin as 30-40 nanometres, that’s impressive. Further, no light polarisation is needed giving an advantage in efficiency over LCDs.

Rahmani did not go into the precise way that you might make a display using the technology, but clearly you could make it transmissive, like an LCD. However, in my view, the technology sounds like a natural kind of area for a reflective system. I couldn’t help thinking of the kind of display made by Etulipa – but then I think about the many years of work needed to go from ‘we’ve got a pixel in the lab’ to an industrialised product!

Non-linear Applications

Prof. Rahmani explained that metasurfaces can convert light color (frequency) but that the efficiency is very poor, limiting the applications. However, his group has already dramatically boosted the efficiency although it is still relatively low.

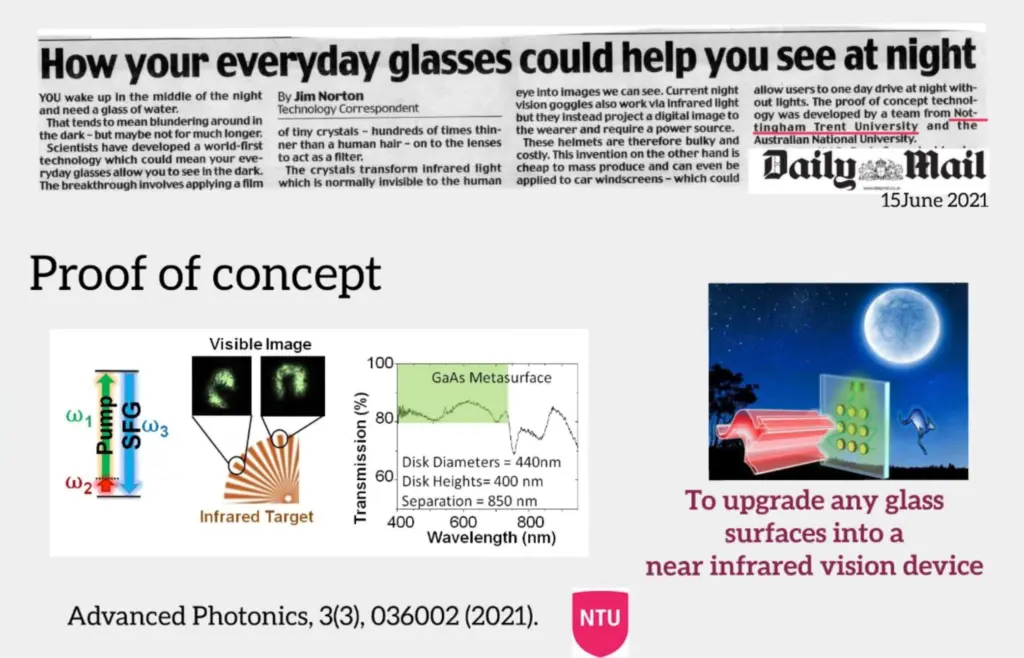

His idea with this technology is to use it to make a film to convert near infrared (NIR) light to the visible region, which would allow you to have glasses that could be used to view in the dark as well as in the daytime. Even on nights with no moonlight, he said, there is plenty of NIR. The metasurfaces can be designed to have no effect on the visible region, while converting the NIR light.

He imagined being able to apply this kind of film to spectacles or even windows or windshields and pointed out what a difference it could make to energy consumption if we didn’t need street lighting!

Bio Photonics

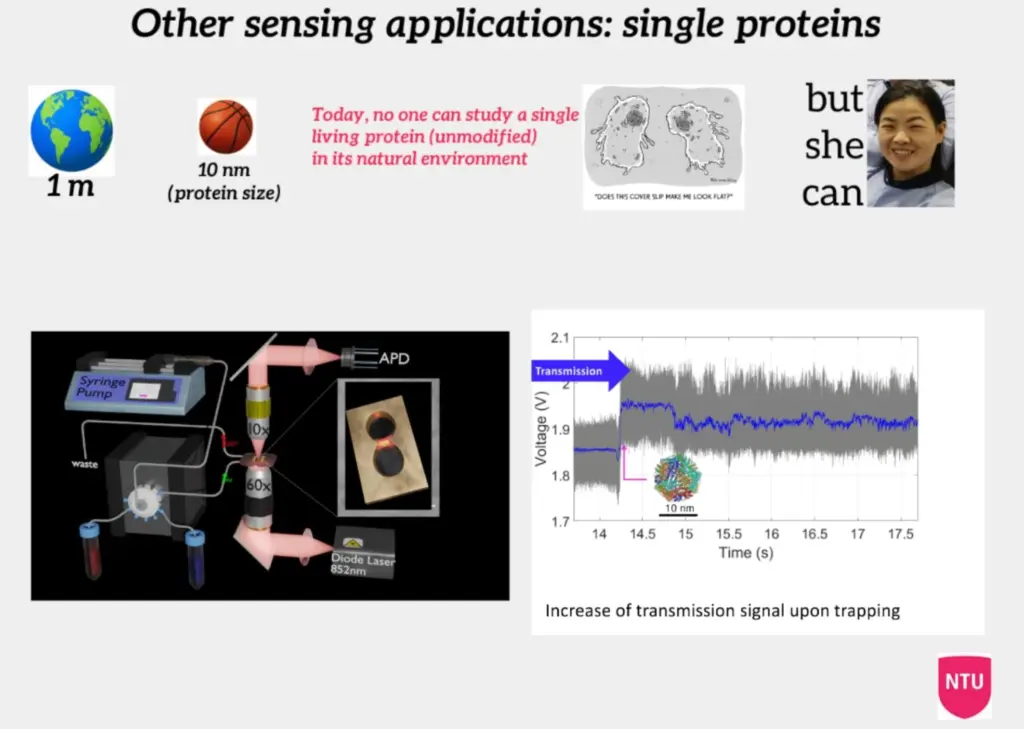

In the third part application area, of bio-photonics, nanomaterials could be used for sensing and have the potential to trap individual proteins and molecules for study and analysis. The technique can be used with gases (which are hard to sense) and, for example can detect toluene and acetone in the breath. His group is working on a number of applications including non-invasive tests for diabetes and early stage breast cancer.

The group has also done a lot of work on the ferrotin protein which controls the use of iron in biological systems. The technology can be used to check if a ferrotin protein is carrying iron or not, helping biologists to study how iron is used in those plant and animal systems. The group is also working on other proteins related to Alzheimer’s and Parkinson’s diseases.

Of Course, There Has to be AI

The big challenge of designing metasurfaces is that there are many parameters and properties that can be changed for different applications. That means that there is a lot of benefit to using AI and machine learning to help with the process and the use of these techniques is also an area for the professor’s group.

In questions, Rahmani told us that its work on the pixels had only been in the lab but it doesn’t see a significant barrier to industrialization although much of the work has been done in the infrared region. Different materials are optimal at different frequencies of light. However, in the detection field, one of the challenges is that while current detectors use different strategies for near, mid and far infrared, nanoparticles can be used for all of them.

Bob Raikes is semi-retired from the display industry, but still edits the 8K Association newsletter and contributes to Display Daily. He was at Display Week for Display Daily, Information Display and others.