FlexEnable is a UK-based company that was spun off from Plastic Logic last year (Plastic Logic Divides into Two Companies), and had space on the Graphene Flagship stand – a collection of companies working with graphene.

In May 2015, FlexEnable announced that it had been working on organic LCD displays (FlexEnable Announces Breakthrough in Manufacturability, Cost and Performance for Flexible Displays), and was showing a curved unit at MWC. The LCD was manufactured on tri-acetyl cellulose (TAC): the same material used for polariser films. Although the materials have low temperature stability, FlexEnable’s manufacturing system does not go above 100°.

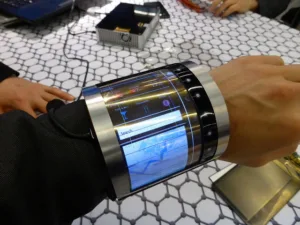

The 0.3mm-thick 4.7″ OLCD display was used in a bracelet-type unit that could be worn on the wrist, although FlexEnable is not a product vendor: it will license the IP to others. We heard that the firm is working with “several companies”, although they were not named. It may be just 18 months before we see the technology in finished products, according to Paul Cain, FlexEnable’s strategy director.

Full-motion video and graphics could be shown. FlexEnable said that it was using an ITO replacement for transistors; although it would not confirm the material used, the company’s position on the ‘Graphene Flagship’ stand should serve as a clue! Transistor performance was described as “the same as a TV”, although was not optimised. Brightness and colour were lower than FlexEnable wanted, and some artefacts were visible on the display.

The unit’s backlight and cell had limited flexibility, and the entire display had a 40mm bend radius: the company is working with OLED to get around this limitation. OLED also has the benefit of being more rugged than OLCD, and can be flexed more often; the OLCD display was encased in a rigid frame.