Reflective LCDs have been around for a long time but have never made much of an impact on the display industry. FLEx Lighting, a US- based startup, is looking to change that with some fascinating technology that greatly improves the performance of reflective LCDs, and just might make this display technology a big part of the industry landscape in a few years.

https://www.displaysupplychain.com/blog/flex-lighting-sets-out-to-transform-reflective-lcd

I visited with FLEx Lighting CEO Mike Casper this week in his company’s office in down- town Chicago to learn more about their technology, and came away impressed with the technology and the opportunities it presents for improving the prospects for reflective LCD. FLEx Lighting recently concluded a series B funding round, raising $9 million from SABIC Ventures, Bascom Ventures, and others, and intends to use the funding to expand its product portfolio to larger sizes.

The main technology behind FLEx Lighting is an extremely thin (50µm) light guide with unique extraction properties that allow for tight control of the light exiting the light guide. FLEx Lighting has patented the core technology for the light extraction mechanism, plus holds additional patents for light coupling and some of the processes used to manufacture and assemble the frontlight unit.

One of the main inhibitors of reflective LCD in the marketplace, in competing against other reflective technologies like electrophoretic (e-paper), is that while reflective LCDs perform very well in direct sunlight, they are not readable in low-light conditions, and traditional frontlight panels do a poor job.

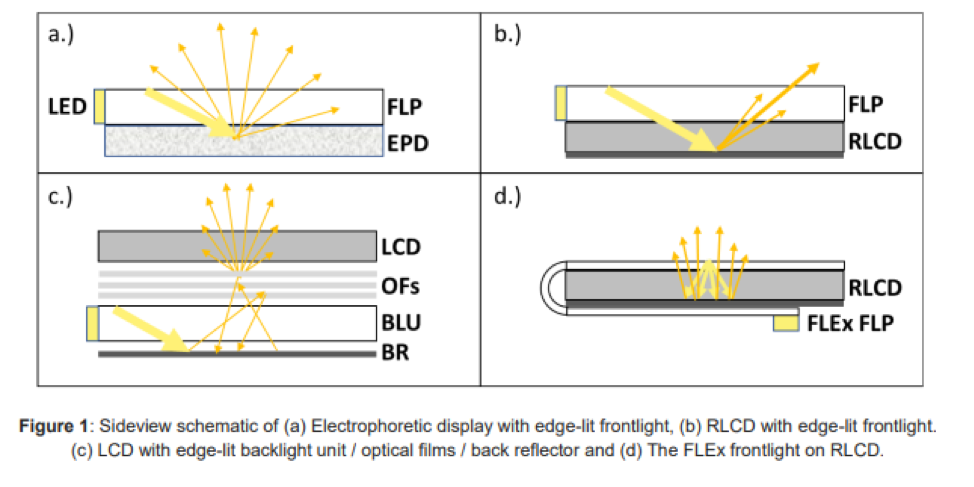

Figure 1 supplied by FLEx Lighting shows a simplified perspective of the problem and the solution. 1a shows e-paper with a typical frontlight at the sides of the display. Because the display is paper-like, the light rays coming from oblique angles scatter in all directions, allowing good readability. Reflective LCDs use a mirror behind the LC layer to reflect incident light, but as shown in 1b the mirror reflects incident light from a frontlight with only a slight scatter. Backlit LCDs, shown in 1c, do not encounter this problem because all the optical layers sit behind the LC layer.

Schematic of Light Scattering for Display Technologies Source: FLEx Lighting

Schematic of Light Scattering for Display Technologies Source: FLEx Lighting

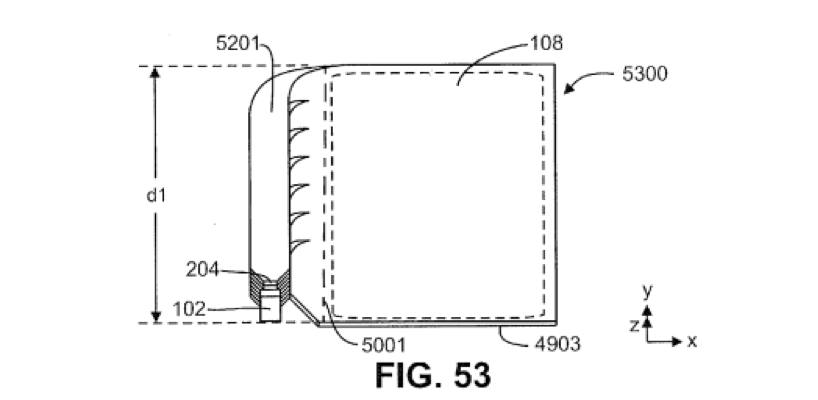

The FLEx Lighting solution is shown in 1d, with a frontlight unit that consists of a thin layer which wraps around the display. The LED for the frontlight sits behind the display, with some special light coupling (more about that later). The waveguide carries the light efficiently as long as the bend radius is not too small (according to Casper, the rule of thumb is that a bend radius of 10x thickness is required to keep efficient light transfer, and this means that FLEx Lighting’s 50µm film can be bent to a radius of 0.5mm). The FLEx Lighting lightguide includes some unique light extraction mechanism which projects the light downward to the mirror, allowing the full amount of light to be available to the display.

The FLEx Lighting system offers many advantages over existing products. Although e-paper has offered some color display systems, the color gamut is far less than LCD. LCD also offers video capability which e-paper cannot match. The thin profile of the FLEx Lighting wave guide keeps the overall display package thin, and the ability to wrap the waveguide around the display to include the LED in the back of the display allows for a bezel-free design. The LED can be positioned close to the wrap-around, or further away, allowing the device maker design flexibility in electronics layout, as shown in the picture.

FLEx Lighting Reflective LCDs, rear view

FLEx Lighting Reflective LCDs, rear view

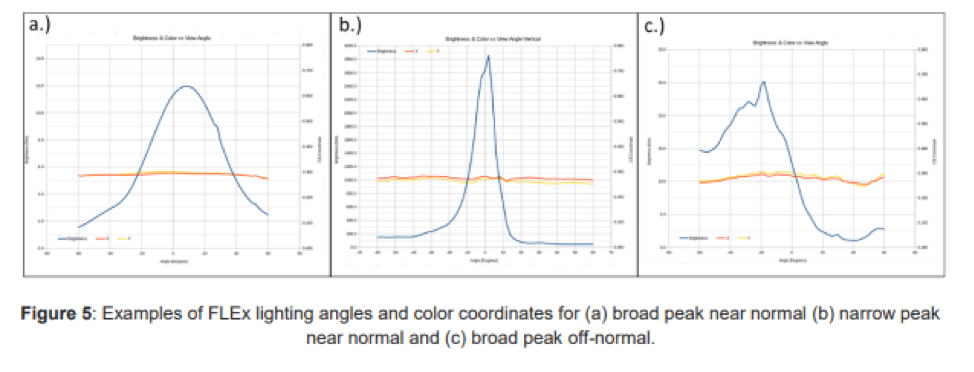

The ability to tightly control the exit angle of light gives the FLEx Lighting approach additional benefits. As shown in the figure below, the light output of the lightguide can be made with a broad peak or a narrow peak or even a peak offset from normal incidence. A narrow peak from the lightguide would presumably give a reflective LCD with a narrow viewing angle, which might be desirable in some applications and undesirable in others, but the design flexibility is undoubtedly an advantage.

Examples of FLEx Lighting Light Guide Output vs Angle Source: FLEx Lighting

Examples of FLEx Lighting Light Guide Output vs Angle Source: FLEx LightingIn considering this technology with a very thin lightguide, one of my first questions was: how do you get efficient light coupling from an LED? This has been one of the issues for glass light guide plates (LGP) for TV, such as Corning’s Iris glass. While Corning would wish to go for thinner LGPs to bring down the glass cost and make glass more competitive with acrylic, it has run into a trade-off with light coupling.

Typical LEDs used for TV displays are 2mm, and light coupling with these LEDs is most efficient with a light guide a little bit thicker. Smaller LEDs are available, but are more expensive in terms of dollars per lumen, so this forces a trade-off between glass cost and LED cost for a TV display using a glass LGP.

?If such a trade-off occurs at 2mm, then how can the FLEx Lighting approach get good light coupling with a waveguide only 50µm thick? If they would need to use 50µm (or even smaller) LEDs, they could get good light coupling but would require many relatively expensive LEDs to do the job.

FLEx Lighting Light Coupling Mechanism Source: US Patent and Trademark Office, US Patent # 9,557,47

FLEx Lighting Light Coupling Mechanism Source: US Patent and Trademark Office, US Patent # 9,557,47

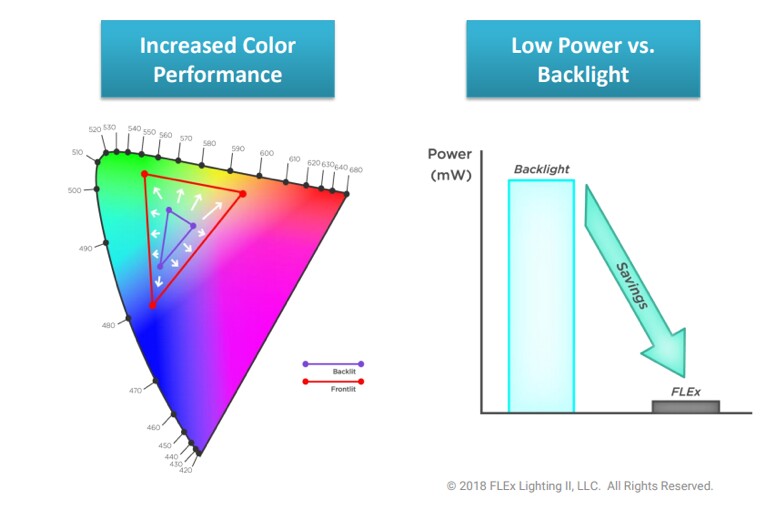

The performance of a reflective LCD using FLEx Lighting’s approach may have manufacturers reconsidering reflective displays. While reflective displays have always offered the benefit of low power, the inability to use these displays in low light conditions has severely limited suitable applications. Although ePaper with a frontlight enabled low light readability, the performance constraints of ePaper for color and video, combined with the higher cost for the technology, have limited e-paper to niche markets. As the picture below shows, though, a reflective LCD with a FLEx Lighting frontlight system can give good contrast and color in both direct sunlight (with the frontlight off) and in a dark room (using the frontlight).

According to Casper, some of the existing reflective display products on the market are designed to look good on the showroom floor, rather than actual use. The Nook was the first front-lit e-reader, and was designed for a brightness of 50 nits to appear bright in a sales environment, but Casper said that in follow-up research e-readers’ designers found that in actual use the brightness was set to on average only 7 nits. Casper noted that a reflective LCD for a 6” tablet display using FLEx Lighting’s technology would require just four LEDs to achieve 50+ nits.

FLEx Lighting says that their technology can achieve better color performance, although I admit I’m not yet convinced. The colors on sample pictures I’ve seen look to be a bit pastel to me. Again, measurement of color for a reflective display is not the same as color for an emissive (or transmissive, like LCD) display, so some of the usual benchmarks may not be appropriate. At the very least, the color for a reflective display depends not only on the display itself, but on the color of the light source.

Source: FLEx Lighting

Source: FLEx Lighting

Casper told me that they will have a demonstration of their technology at the CES show in Las Vegas in January. I will certainly be seeing that demonstration, and DSCC Weekly Review readers will see more of this fascinating technology. – Bob O’Brien

Thanks to DSCC for giving us permission to run this article in the ‘guest’ slot. The original was a joint article in the Display Supply Chain Monitor.