One might think that low-to-moderate brightness displays are fine for virtual reality applications as it is an immersive experience and users can easily adapt to low luminance levels. But that is not the case stressed Olivier Prache, Senior VP, Display Operations at eMagin and CEO & President Andrew Sculley on a recent visit with the company. “Once you consider the performance requirements that VR headset makers are requesting, along with optical losses, you quickly get to the conclusion that 4500 nits of peak luminance is necessary for immersive VR applications,” stated Sculley. “We have spent a lot of time educating VR headset designers about this need and they are finally starting to understand.”

At last SID DisplayWeek, eMagin showed a 1920×1200 resolution OLED panel that was producing 4500 cd/m² of peak luminance. This was fabricated with a RGB direct emission OLED structure, not the white OLED/color filter approach the company has historically used.

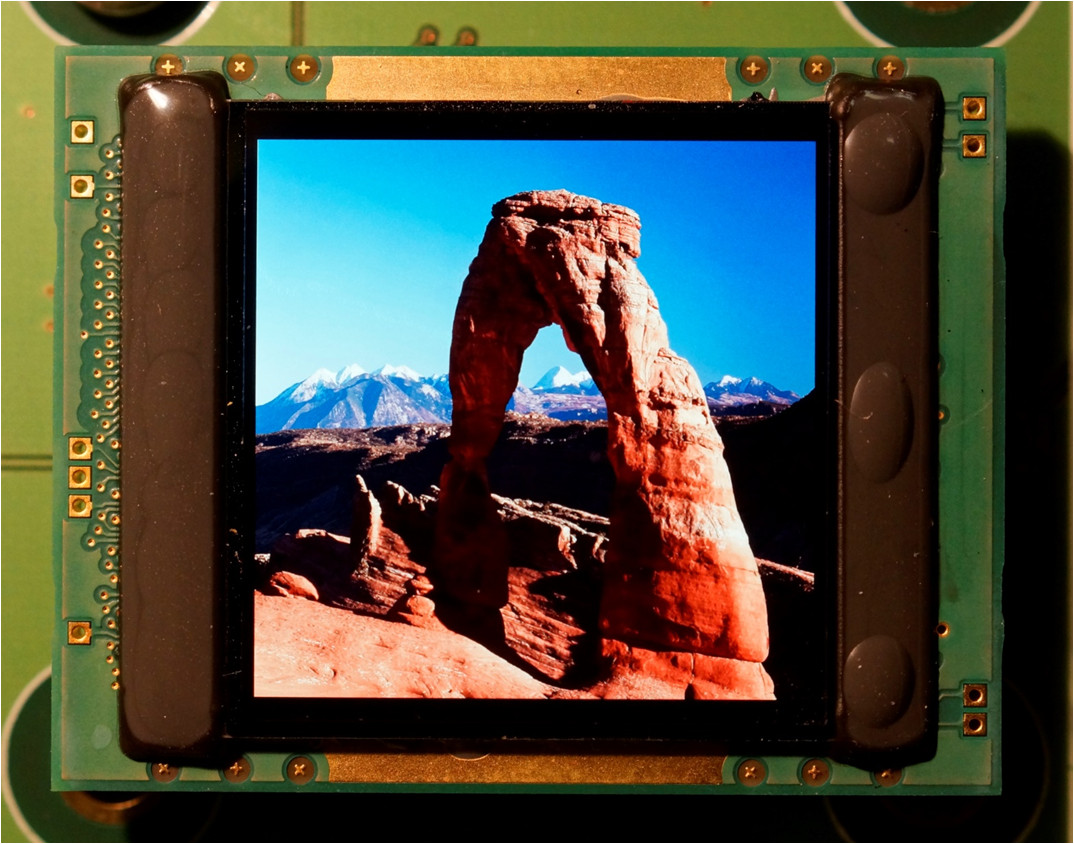

In its second iteration of development for VR customers is a new 2Kx2K (2072×2072) resolution panel in a 1.04” diagonal form factor (9.3 micron pixel pitch). This has been shown in two luminance ranges: the XL series with 150-200 cd/m² and the XLS series with 800-1000 cd/m². These feature white OLED and RGB color filter technology, not the direct pattern RGB technology.

Engineering samples of the direct patterned 2K x 2K microdisplay with 4500 nit range, will be shipping mid-year to late summer. eMagin can create such displays in small numbers, but to satisfy the needs of the VR market, the company needs to scale its production capacity. For consumer level mass production of OLED microdisplays, no company, perhaps with the exception of Sony, currently has the capacity on-line

“As a result, we have been discussing investment and mass production possibilities with our supply chain partners.” noted Sculley. “Mass production will be enabled through strong partnerships that we are building in the consumer segment. We feel very good about current on-going discussions here and hope to make announcements in the near term.”

Prache then provided some more insight into how eMagin reached the conclusion that high luminance is critical for immersive VR applications.

“For one thing, to reduce motion blur, headset makers want to run the displays with a low on-time duty cycle (also called Low Persistence),” explained Prache. “This black time insertion is needed, even with high frame rates. For gaming, we have heard a duty cycle as low as 10% and no one is talking over 50%. A 10% duty cycle means you need ten times the peak light output in this time frame. If you combine this with high quality, but inefficient optics (as low as 10% throughput), you are talking about a factor of 100 for the increase in display peak luminance to achieve an average luminance to the eye of 45 cd/m² . As far as we know, no one else can support a 10% duty cycle the way our OLED panels can.”

Sculley added, “Even if you develop an HMD application that doesn’t require high brightness, our direct patterned microdisplays offer huge advantages in longer lifetime and lower power requirements.”

We then took a look in the company’s development lab where Prache and others are working on next generation OLED panels. Here, he explained that their current color-by-white OLED panels can achieve about an sRGB color gamut, but the direct pattern RGB process will offer a bigger DCI-P3 color gamut. The 2Kx2K panel can support frame rates up to 120 fps although the current drive board is limited to 60Hz.

Inputs to the panel are 8-bit per color, but eMagin uses a 10-bit LUT to smooth out the gamma curve and tone mapping to eliminate any banding.

Can eMagin offer a 4K x4K panel we asked?

Yes, if they move to a 7 micron pixel pitch. So far, they have only fabricated panels with as small as an 8.1 micron pitch. The smaller pitch is needed to allow lithography step exposures in a conventional 25x25mm field and avoid stitching. Many tools have this sized field but some can go up to as big as 50x50mm.

Avoiding stitching will further enable eMagin to meet cost targets in the high volume VR applications they are targeting. They are talking to suppliers and potential mass production partners to ensure that they will be able to deliver on this. The 2Kx2K panel also has another unique feature: the ability to drive various sized windows as small as 512×512 pixels. These can be driven with alternative content and moved around to support overlay of graphics, for example. It can also be used to support foveated rendering and can help to save power.

The smaller window capability also allows the use of higher frame rates (up to 590 fps for a 512 x 512 window). In addition, operating the 2Kx2K display with a lower input format also translates to lower power consumption as the display architecture blanks the un-addressed portion of the display automatically

The microdisplays also implement a global shutter mode to minimize motion artifacts on faster moving objects.

Currently, around 70% of eMagin’s revenue comes from defense, security and military applications. But they are increasingly seeing more professional and consumer applications develop. For example, they are being used in a head-mounted display worn in the field by veterinarians for ultrasound imaging and for training of students in Lasik surgery. Another application is the consumer Riflescope market. Such scopes can cost from $7K to $10K, but there appears to be a ready market for them (a new Riflescope Market report says the market is estimated to grow from $5.36 Billion in 2016 to $6.87 Billion in 2022 due to increased popularity of shooting sports and animal hunting).

As for the 2Kx2K display, eMagin is already working with AMD on a VR headset using the 2Kx2K panels (see AMD Working with eMagin on 4K VR – subscription required). eMagin will be demonstrating the 2K and direct patterned high brightness microdisplays at the upcoming SID DisplayWeek Expo. That will definitely be worth checking out. – CC