Dr. Evan Donoghue of eMagin recently gave a talk for the SID Mid-Atlantic Chapter (SID-MAC) on eMagin’s direct patterned OLED microdisplays. These microdisplays are primarily targeted at head mounted displays, especially see-through augmented reality (AR) HMDs for the military. Dr. Donoghue’s talk was largely based on an invited talk, paper 62-1, presented by Dr. Amal Ghosh with Donoghue as the second author. They had 5 other co-authors from eMagin plus two from the US Army Night Vision and Electronic Sensors Directorate.

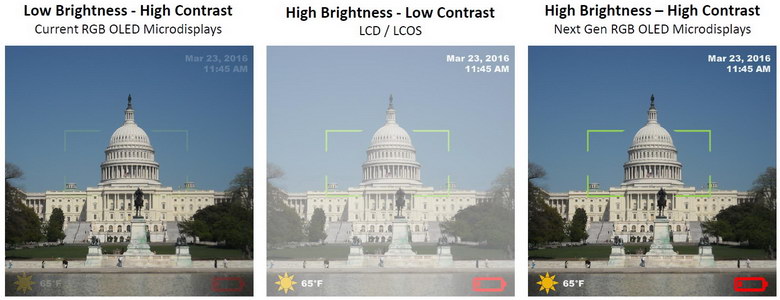

High contrast and high brightness is needed for see-through AR (Image: eMagin)

High contrast and high brightness is needed for see-through AR (Image: eMagin)

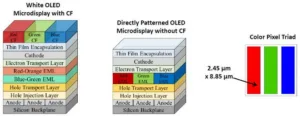

Microdisplays for see-through AR applications must have both very high brightness and very high contrast. The high brightness is needed so the AR information can compete with high ambient light of outside world, especially in daylight. Conventional eMagin OLED microdisplays do “color-by-white” which involves unpatterned white OLEDs and color filters. According to Dr. Donoghue, the color filters discard about 80% of the light from the OLED, leading to brightnesses limited to about 750 cd/m² (nits). While these OLEDs can have very high contrast, that brightness isn’t sufficient for see-through, outdoor AR applications. The information augmenting the see-through image is simply not bright enough to compete with the outside world, as can be seen in the left image above.

LCD and LCoS systems can have arbitrarily high brightness, depending on the power of the LEDs illuminating the microdisplay. On the other hand, the contrast is fairly low compared to OLEDs. When the LCD or LCoS is driven bright enough for outdoor see-through AR systems, there will be a white haze over the entire image, as shown in the center image, above.

eMagin’s solution to this problem is to pattern red, green and blue OLED materials onto the sub-pixels of a single microdisplay. This allows the color filter to be eliminated from the system and the brightness to dramatically increase. They are still OLEDs, however, with very low dark-state emission. This high brightness and low dark state then provides an outdoor, see-through AR image where the displayed information is easily visible against the background while the low dark state eliminates the visible haze, as shown in the right image above.

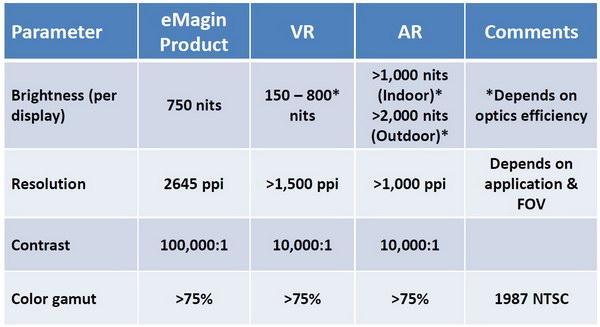

eMagin “color-by-white” microdisplays compared to the needs of VR and AR applications. (Image: eMagin)

eMagin “color-by-white” microdisplays compared to the needs of VR and AR applications. (Image: eMagin)

The table compares standard eMagin full color microdisplays to the needs of VR and AR applications. As can be seen, these microdisplays meet the requirements for VR applications but are not bright enough for AR applications, especially outdoor AR applications. I feel the 2,000 cd/m² in this table is definitely a minimum for outdoor AR and I’ve been told 4,500 is a better target. Some people are talking as much as 10,000 nits for outdoor AR. As a comparison, however, Dr. Donoghue said monochrome green OLED microdisplays can have up to about 23,000 cd/m² brightness.

In addition to competing with the outside world, another reason very high brightness is needed from the microdisplay is because the optics of see-through AR optical systems are often very inefficient and up to 90% of the light from the microdisplay can be lost to the viewer. With an 80% loss at the color filters an and additional 90% loss in the optical path, only about 2% of the light from a color-by-white OLED gets to the viewer.

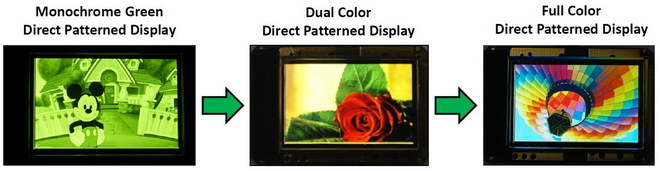

eMagin’s development path for direct-patterned OLEDs. (Image: eMagin)

eMagin’s development path for direct-patterned OLEDs. (Image: eMagin)

eMagin’s development path for direct patterned OLEDs started with patterning just green OLED materials. This involved three green sub-pixels on a standard eMagin silicon backplane. A direct patterned green OLED has little advantage over an unpatterned green OLED, other than teaching the patterning technology. According to Dr. Donoghue, the patterned green display was virtually identical to the eMagin standard unpatterned monochrome green microdisplay in terms of both color spectra and drive characteristics.

The next step was a dual color system with two red sub-pixels and one green sub-pixel for every pixel. This design achieved 8,000 nits output and, in fact, the military has interest in dual-color displays even if there is no consumer interest in two-color displays. The final development step was patterning all three colors of red, green and blue OLED materials. This design achieved about 3,500 nits output. Dr. Donoghue said that the direct patterned full color microdisplays are expected to reach 4,500 nits. Or perhaps they have already achieved 4,500 nits since the Army limits what eMagin can say publicly. The eMagin website product page currently says “over 4000 nits demonstrated” on an engineering prototype.

The stacks eMagin uses for its OLED microdisplays. Left: conventional “color-by-white” microdisplay. Center: Microdisplay with patterned red, green and blue OLED materials. Right: Sub-pixels size of a color pixel triad. (Image: eMagin)

This image shows the stacks used by eMagin for its OLED microdisplays. The one on the left is “color-by-white” with color filters to generate the red, green and blue. Note that “white” OLED material is actually two layers of OLED, one red-orange and the other blue-green. In the center image, the stack used by the direct patterned OLED is shown. Note there is no color filter in the stack. In both designs, the hole injection, hole transport and electron transport layers are unpatterned. Dr. Donoghue said this leads to a little crosstalk between the red, green and blue sub-pixels. Due to the exaggerated vertical scale of these stacks, this problem is not as bad as it looks: vertical dimensions are measured in angstroms while horizontal dimensions are measured in micrometers.

The development work for direct patterned OLEDs was done on WUXGA (1920×1200) backplanes on an 8” single crystal silicon wafer. eMagin used phosphorescent OLED materials from Universal Display Corporation for green and red and a fluorescent blue OLED material. Fill factor is about 70%.

As a conclusion, Dr. Donoghue said, “This technology will propel VR/AR wearables technology to new heights.” This is especially true for see-through AR because VR applications rarely need brightness levels beyond what can be achieved by eMagin’s color-by-white OLED microdisplays. Since this development work was done on standard WUXGA backplanes on standard 8” wafers, it should not take much to implement these designs in products for the US Army. Cost is not a major problem to the Army, but eMagin wants to expand its market into civilian applications (See eMagin Develops Night Vision Systems in this issue). For consumer applications such as these night vision systems, cost is a much more serious issue. – Matthew Brennesholtz