eLux said that it has been awarded a US patent 9,825,202 titled “Display with Surface Mount Emissive Elements” for a microLED display based on assembly using massively parallel fluidic assembly. The company is aiming to develop displays that can exploit the performance of microLEDs with the infrastructure of TFT LCDs.

eLux claims that it can assemble microLEDs at 50 million per hour.

“We believe that the fluidic assembly methods developed at SLA and eLux will enable low cost µLED displays for video walls and ultimately television,”

explained Paul Schuele, eLux’s CTO and an inventor of the technology.

The company has previously acquired twenty patent families related to fluidic assembly from Sharp.

Patents acquired from Sharp which are most closely related to the technology covered by US 9,825,202 are:

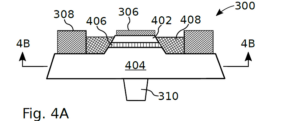

- US 9,722,145 covering a direct emitting display with vertical µLEDs manufactured by fluidic assembly methods.

- US 9,755,110, which covers the well structures used to precisely position the assembled µLEDs in an array.

- 15/190,813 (allowed) is the foundational patent for the structures that can be used to orient µLEDs (or other components) with one polarity.

- 15/266,796 (allowed) covers the use of through-hole vias to enhance the yield and selectivity of fluidic assembly.

- 15/197,266 (allowed) is a color conversion structure using quantum dots to generate red and green colors from blue µLEDs.

In late May 2017, Hon Hai Precision Industry and Sharp Corporation in partnership with CyberNet Venture Capital, Innolux and Advanced Optoelectronic Technology announced investment in eLux, Inc. (Sharp Buys eLux)

Analyst Comment

Although 50 million microLEDs per hour sounds like a lot, if the LEDs are single colour that only means around two UltraHD panels!

We’ve been reporting on FSA since the launch of the concept in displays by Alien Technology at the SID in 1999, before getting the “curse of an SID award” with the Gold Display Component of the Year award in 2002. The idea is that chips are suspended in a fluid which flows over a substrate and some of the chips precipitate out to stay on the substrate. The plan was to create tiny crystal silicon transistor chips that would be used in place of the TFTs in LCD substrates. Alien found it difficult to compete in displays and pivoted to become a supplier of RFID technology. (BR)