Markus Ries of Lang Ag in Germany liked the slide from Compound Photonics (DS6 Compound Photonics Challenges Projector Makers) that said that projector makers do not listen to customers. He explained that Lang is a rental and A/V company based in Germany, near Cologne. The company works with flat panel displays, but is also interested in projection. The company has worked on Laser Phosphor projectors for a long time, but there are no single chip L/P projectors that can do a ‘proper Rec.709’. That is a big problem for Lang. LP also produces more rainbow effects because of the segmented colour wheel, combined with the segmented phosphor wheel. The image quality of three-chip DLP projectors is good, but they are big, heavy and expensive compared to lamp-based units.

Laser phosphor + 3LCD is a good combination, as 3LCD has better colour quality than sequential DLP. Size and weight are important for rental – Lang’s projectors spend 95% of their time on the road. Sony made some good 3LCD projectors, but they were not designed for rental and staging. 65% of Lang’s inventory is 10K or 20K lumens – the bigger ones are more profitable. 99% of the products that Lang has in its inventory are based on DLP, but only 0.9% was 3LCD. So, Lang started talking to Seiko Epson.

Ries said that his own staff thought he was ‘crazy’ to consider going to 3LCD. Why did it disappear from the rental market? 10 or 15 years ago they were good products, but they disappeared as they used to be XGA and maintenance costs were high. They were air cooled, which meant that they got dirty, so the cost of ownership was high and the organic components degraded. It wasn’t image quality that was a problem, it was cost & reliability.

So what do you need? Several features are really necessary, such as 50% lens shift. No special modes are required, but pre-calibrated Rec 709 and sRGB would be very useful. The optical block has to be sealed for low maintenance. Ries said that there are two new product lines from Epson, the L25000 series (launched at Infocomm) and the L1000 series (launched at ISE). More products are coming with higher resolution and brightness.

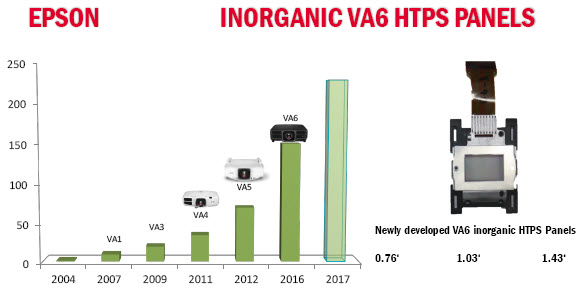

Epson’s VA6 panels have inorganic alignment layers, prolonging the useful life

Epson’s VA6 panels have inorganic alignment layers, prolonging the useful life

New inorganic HTPS panels are a significant improvement and Ries showed a chart of good improvement in panel reliability. Add that to a Laser Phosphor (LP) light source. With LP there is no UV or IR light, so you don’t need to worry about the effect of U/V on the reliability of the panel. Also, Epson has developed its own ceramic phosphor that gives better long term reliability than wheels from other vendors. You can make these phosphors on top of a reflective surface, boosting the light output. The light path is similar, in broad concept, to traditional models, but there are a lot of details – e.g. using a reflective wheel to reduce speckle, compared to diffuser wheels.

Ries doesn’t like ‘virtually maintenance free’ products, he wants completely maintenance free.

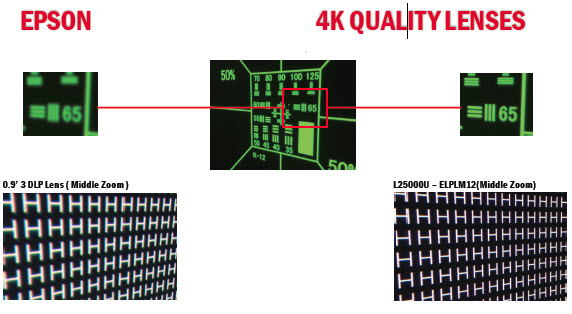

Ries said that lenses for DLP were not good enough for data, although OK for 4K cinema

Ries said that lenses for DLP were not good enough for data, although OK for 4K cinema

Another point of concern is the lenses. Ries said that DLP lenses are not really good enough for 4K data, but the Epson has a genuine 4K lens. He said that the 4K chip from TI is big and so lenses have to be very big to really get good images. The Epson lenses can cover even 8K – and they can cover the full lens shift. Next year Epson should produce units with native 4K panels.

Ries believes that eventually all projectors go fully laser, while L/P will have a life of 3-6 years. Laser with high brightness will be expensive in the shorter term. Engine design becomes much simpler with direct RGB laser. The analogue sunset is coming.

The chip sizes used are 0.76″, 1.03″ and 1.43″ in WUXGA – the new 4K LCD will be the largest.

In questions, Ries said that for Lang, 25K lumens with 50/60 Kg is fine. In terms of lifetime, 5K to 6K hours is about the limit because of technology creep and obsolesence (e.g. inputs change over time). Reis said that Epson’s warranty covers 20K hours and five years, which is enough.

Analyst Comment

Later in the week, Lang said that it had placed a big order with Epson for projectors. Epson Works on Laser With Lang