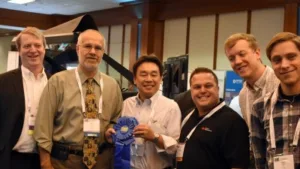

1. Bob O’Brien (left) and Silviu Pala (next to O’Brien) present the best booth in show award to an apparently delighted 3M team. (Photo: Ken Werner)

1. Bob O’Brien (left) and Silviu Pala (next to O’Brien) present the best booth in show award to an apparently delighted 3M team. (Photo: Ken Werner)

On the second day of the exhibits, Silviu Pala, Director of the SID Metro Detroit Chapter (which sponsored the event) announced that 3M had won the award for the best exhibit in show (Fig. 1). 3M’s winning effort was a mock-up of a vehicle’s dash and windshield that managed to demonstrate many of the company’s featured products (Fig. 2).

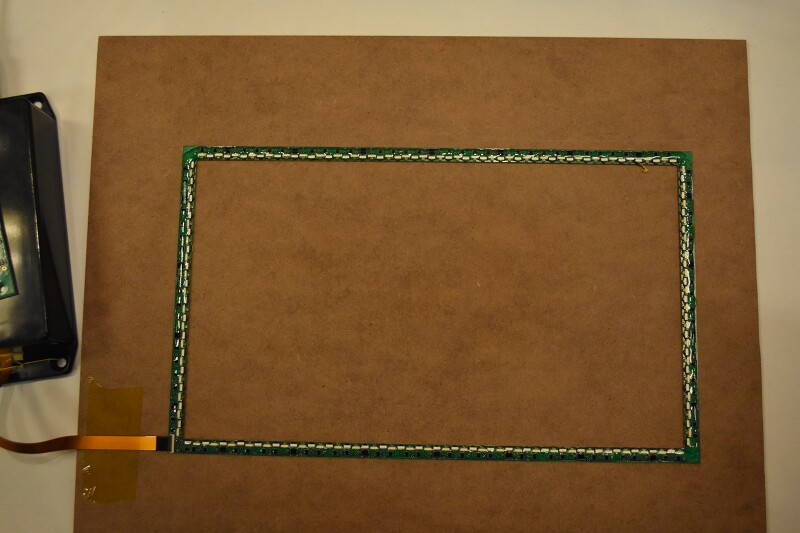

2. The prize-winning 3M mock-up, which managed to show off 3M’s combiner film, IR rejection film, advanced light control film, and “camouflage flim,” all at once. (Photo: Ken Werner)

2. The prize-winning 3M mock-up, which managed to show off 3M’s combiner film, IR rejection film, advanced light control film, and “camouflage flim,” all at once. (Photo: Ken Werner)

In the upper part of the demo, a HUD display image is reflecting off of 3M’s combiner film. The film is laminated inside the windshield glass to avoid the typical HUD double image. The current solution is to incorporate a wedge shape in the windshield, which OEMs and Tiers would like to avoid. The industry is responding very positively to the new film, said 3M Senior Research specialist John VanDerlofske. Another product is an IR rejection film, which 3M would like to combine with the combiner film.

3M also used the demonstrator to show its “advanced light control film,” which incorporates a louver structure in the film to limit instrument reflectons in the windshield. This film offers design freedom, said VanDerlosfske. For instance, designers to not have to include a “brow” over the instrument cluster to block light from reflecting off the windshield if the film is doing it. Also shown in the demo was the film being used to limit side reflections from electronic side view mirrors.

Also shown was a “camouflage film” which can be printed with a desired pattern and hide an IR camera while being transparent to the IR light.

3. Harman’s auto-qualified 13.3-inch QLED display with 1100 cd/m² and 110% gamut using cadmium-free QDEF materials. (Photo: Ken Werner)

3. Harman’s auto-qualified 13.3-inch QLED display with 1100 cd/m² and 110% gamut using cadmium-free QDEF materials. (Photo: Ken Werner)

Harman/Samsung‘s new international UX Group introduced a “production-grade, auto-qualified” QLED display (Fig. 3). The display was derived from a 13.3-inch notebook PC panel with 67% gamut and 400 cd/m² luminance. With the addition of a much brighter blue-LED backlight, luminance rose to 1100 cd/m² (typical). The gamut increased to 110% with cadmium-free QDEF materials and no change in the color filter.

Also new was the glove-sensitive touch instrument display introduced in a Harley-Davidson motorcycle three weeks ago. The display took three years to develop, said UX Group Director Rashmi Rao. The touch screen has to be sensitive enough to work reliably when the user is wearing a glove, and yet not give false activiations in the rain. “This was challenging,” she said.

In addition, there was a comparison of touch screens using silver nanowire, copper nanowire, ITO, carbon nanotubes. There were noticeable differences in transparency, black level, white level, and white-level reflection off the nanowires. The one-box demonstrator will allow Harman to conveniently show customers the differences and help them choose what is best for their applications, said Rao.

4. AUO America laminated a single piece of 1.1-mm cover glass laminated over three separate displays to provide an integrated look. The central display is drilled knob shafts. (Photo: Ken Werner)

4. AUO America laminated a single piece of 1.1-mm cover glass laminated over three separate displays to provide an integrated look. The central display is drilled knob shafts. (Photo: Ken Werner)

AUO America showed three displays in the same plane with a single piece of 1.1-mm cover glass laminated over all three (Fig. 4). The right-hand displays used LTPS and had in-cell touch. Center display, which was drilled accommodate knob shafts, used gate circuits in the active area.

5. Sharp demonstrated its “progressive super-low reflectivity” (PSV) AR film, which reflects only 1% of incident light, said Sharp. (Photo: Ken Werner)

5. Sharp demonstrated its “progressive super-low reflectivity” (PSV) AR film, which reflects only 1% of incident light, said Sharp. (Photo: Ken Werner)

Sharp showed a 10.1-inch demo module that was curved vertically and had full in-cell touch. In addition, the company demonstrated what Sharp’s Yoshihiro Naka called “the next generation in anti-reflection technology.” The film features “progressive super-low reflectivity” (PSV), reflecting only 1% of incident light (Fig. 5). A side-by-side comparison was impressive.

Sharp’s free-form displays were being shown elsewhere, but one is now in a vehicle, said Naka.

6. Kyocera’s autostereoscopic HUD eye tracking and two eye points delivered a stable 3D image. (Photo: Ken Werner)

6. Kyocera’s autostereoscopic HUD eye tracking and two eye points delivered a stable 3D image. (Photo: Ken Werner)

Kyocera Display showed an autostereoscopic HUD that used one of the company’s TFT-LCD displays intended for HUD applications (Fig. 6). There was visible pixelation, but the 3D image was stable and seemed as if it would actually make navigation easier. Kyocera said the HUD monitored driver eye position and “minimized reduction of resolution by two eye points 3D display.” There was an improved version of Kyocera’s “Haptivity” display, which is now 18 months from commercialization, a Kyocera rep said. There was also a new, larger (3.1-inch) member of the company’s TFT for HUD line.

7. This is Tru Vue’s sputtered multi-layered AR coating with 0.3% reflectivity per surface. (Photo: Ken Werner)

7. This is Tru Vue’s sputtered multi-layered AR coating with 0.3% reflectivity per surface. (Photo: Ken Werner)

Tru Vue showed its multi-layered sputtered AR coating with 0.3% reflectivity per surface (Fig. 7). There was also a curved plastic, 1920 x 720, anti-reflective OLED display using an LGD panel. Tru Vue does its own bonding. The OLED display does not yet meet automotive temperature specs, which is an industry-wide issue.

Luminit was showing a laser-based HUD that reduced the volume of the engine to less than 1.5 liters. That would permit a wide-FOV, large-eye-box HUD to fit under the dash of a vehicle smaller than a Chevy Suburban.

Tianma showed a 12.3-inch instrument cluster display with 1920 x 720 pixels and direct local dimming. Luminance was 1000 cd/m², gamut was 75% of NTSC.

8. AD Metro’s linear correlating infrared (LCIR) touch touch frame is guarantee to be reliable in bright sunlight. (Photo: Ken Werner)

8. AD Metro’s linear correlating infrared (LCIR) touch touch frame is guarantee to be reliable in bright sunlight. (Photo: Ken Werner)

AD Metro (Ottawa, Ontario) demonstrated its linear correlating infrared (LCIR) touch technology (Fig. 8). Because reception of the IR pulses is correlated with their transmission, the system is reliable in bright sunlight and in the presence of strong RFI, said Sales Engineer Sabastian Coloma. The preliminary data sheet specifies full immunity to sunlight, 0.08-inch touch resolution, and the use of a compact USB 2.0 controller. The current system offers two-touch capability, and is usable with glove or stylus. NVIS versions are available. Response time is less than 10ms.

GE showed its TriGain potasium fluorsilicate Mn++ (PFS) RadiantRed phosphor. This is the same basic phosphor as the previous version but it now exhibits better environmental resistance. The phosphor has a narrow emission characteristic, and TV and smart phone displays using blue LEDs enhanced with red and green phosphors in the package can produce excellent color gamuts. A GE rep said RadiantRed provides a red that is superior that from quantum dots. As is well known, GE doesn’t have have a companion green phosphor yet. The rep said GE’s customers obtain their green from another supplier, but GE is working on it. For now, GE is happy. Sales are up sharply up, the rep said.

Incidentally, it is hard to get customers to say whose phosphor they are using. It is likely that Samsung uses RadiantRed in their NU series of TVs, which is the series just below the quantum-dot containing Q series. It is possible that Sony’s Z9 also uses the phosphor. You can find out for yourself if you have a spectrophotometer. The emission characteristic of RadiantRed has three closely spaced peaks, which are distinctive. You can see the waveform at http://www.geradiantred.com/about/.

Radiant Vision Systems demonstrated a sparkle detection and measurement system. Radiant’s Shaina Warner said Japanese car manufacturers are using it for all anti-glare displays and layers. She said the company has developed a lens that enables a 120° view for testing AR/VR headsets.

The new development from TFEL-maker Lumineq was a TFEL touch display embedded in curved glass. The company patterns the ITO to prevent the high TFEL voltage from interfering with the touch panel.

Global Lighting‘s new offering is a 50k cd/m² backlight unit that is thin enough to couple with a 0.25mm-thick light guide. The ring light guide that is used in an aftermarket surround for the Chevy Volt’s charging port hasn’t found other automotive applications, but the technology is being used in Simple Human make-up mirrors.

9. Neonode’s Airbar™ linear IR touch technology is now included in 30 Chinese auto models, including the Volvo S90. (Photo: Neonode)

Neonode showed the latest version of its Airbar IR LED touch sensor. The Airbar is linear, with its LEDs and sensors side by side. Transmission and reception are correlated. Thirty Chinese car models already incorporate Airbars, including the Chevrolet New Cruze and Volvo S90 (Fig. 9). Michael Blicher, Neonode’s business development head, said the company is in serious discussions with OEMs and all tiers, who like the idea of a touch technology that does not produce finger smears on the display. An interesting application, said Blicher, is to use a curved version of the Airbar on or in the periphery of a steering wheel. The device can sense not only that the driver’s hands are on the wheel, but also where on the wheel. Neonode also had a demo (not working when I saw it) of holographically generated spatial buttons that used the Airbar to sense a spatial “touch”

E-Skin Displays “has invented the world’s first full-color plasmonic structural color paint/display, angle-independent, structural color paint that never fades,” said CEO Nagendra Nagarajayya. The color is structural in that it uses iridescent structures instead of pigments. Therefore, the color doesn’t fade. Reflectivity can be as high as 95%, he said. Since the paint can be made in high volumes at reasonable cost, it can be used for cosmetics, printer ink, plastics, and dyes, as well as for automotive finishes. With the addition of a thin layer of liquid crystal, the application of a voltage can change the color and pattern of the plasmonic flakes, said Nagarajayya. Their “plasmonic display” uses subtractive CYM subpixels to map the entire CYMK color space.

In an email communication, Nagarajayya wrote that it took Lexus, inspired by the Blue Morpho butterfly, 15 years to develop their structural color blue. “Lexus uses a painstaking process to make the 300 billion nano flakes, taking more than eight months to make the paint. We…can make these flakes at scale; while Lexus can only make Lexus Blue, we can make…all colors in the CYMK space.” (KW)