Display companies are getting onboard with sustainable manufacturing, the process of designing and producing products in an environmentally responsible and resource-efficient manner. Products are being built with a view to energy efficiency, the use of green and recyclable materials, and better management and oversight of the supply chain.

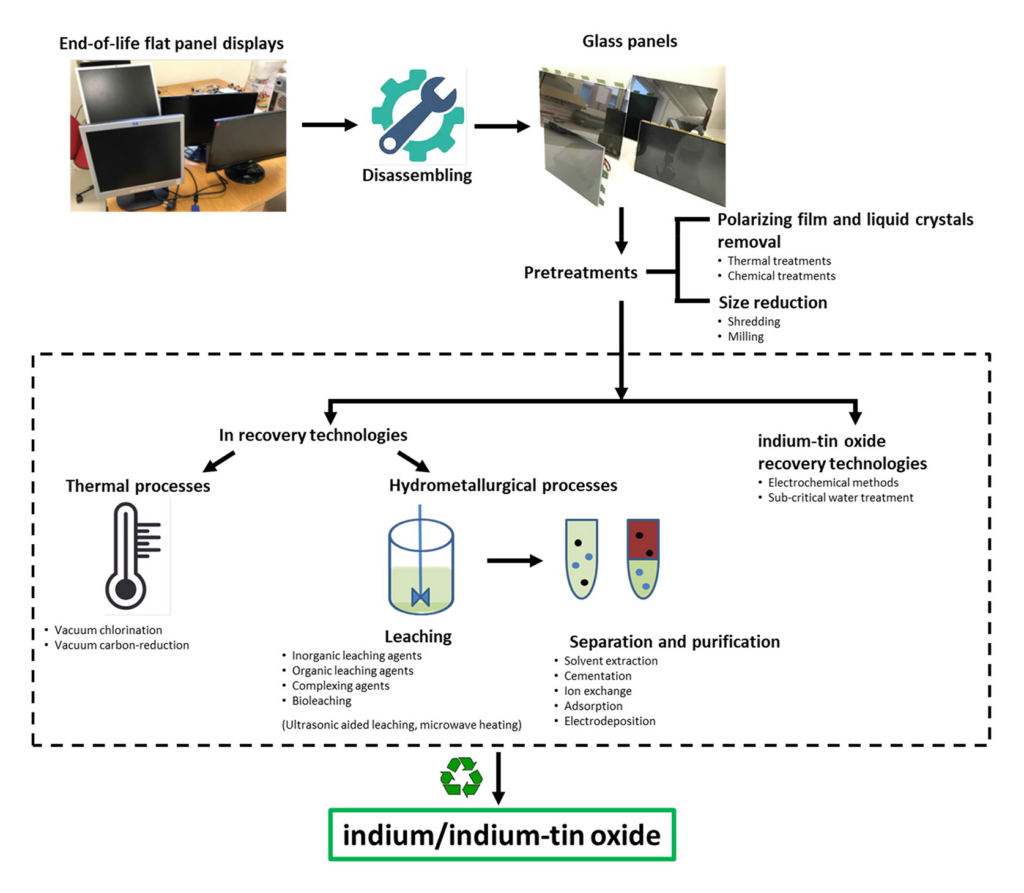

Back in 2017, Vizio was awarded a Sustainable Materials Management (SMM) Electronics Challenge Award by the EPA. Only last year, eLoop unveiled a process for end-of-life flat panel TV reclamation that using a robotic AI processing system. Samsung and LG have been very vocal in their support of sustainable manufacturing.

There are a lot of standards, processes, and initiatives for sustainability. We’ve seen IT monitors that have TCO certification. Some of the most important standards and certifications for sustainable manufacturing include:

- ISO 14001: a framework for environmental management systems. It sets out requirements for an organization to minimize its environmental impact and continually improve its environmental performance.

- LEED: The Leadership in Energy and Environmental Design (LEED) certification is a rating system that evaluates the environmental performance of buildings and manufacturing facilities. It covers a range of sustainability criteria, including energy efficiency, water conservation, and waste reduction.

- EPEAT: The Electronic Product Environmental Assessment Tool (EPEAT) is a global registry for electronics that evaluates products based on their environmental attributes. It considers factors such as energy efficiency, material selection, and end-of-life management.

- Fair Trade: The Fair Trade certification ensures that products are produced in a socially and environmentally responsible manner. It covers a range of sustainability criteria, including fair wages, safe working conditions, and environmental protection.

There are also regional initiatives. The South Korean government has launched several initiatives to promote sustainable manufacturing and reduce greenhouse gas emissions. These include the Green New Deal, which aims to create jobs in the green sector and transition the country to a low-carbon economy. South Korea has also established a voluntary carbon trading scheme, and introduced a carbon tax in 2021.

The Chinese government has set ambitious targets for reducing carbon emissions and promoting sustainable development. The country’s 14th Five-Year Plan includes targets for energy efficiency, renewable energy, and emissions reduction, as well as measures to improve air and water quality. China is also home to the Green Supply Chain Initiative, which aims to promote sustainable practices throughout the supply chain. Japan has the Cool Earth Partnership, which provides support for developing countries to reduce emissions and adapt to climate change. It has also established the 3R (Reduce, Reuse, Recycle) Initiative, which aims to promote the efficient use of resources and reduce waste.

In addition to these government-led initiatives, there are also several private sector initiatives in these countries that promote sustainable manufacturing. For example, many Japanese companies have adopted the concept of “mottainai,” which means to reduce waste and make the most of resources. In China, the China Business Council for Sustainable Development (CBCSD) promotes sustainable development among Chinese businesses, while in South Korea, the Korea Green Manufacturing Industry Association (KGMA) works to promote sustainable manufacturing practices. In Taiwan, the Industrial Technology Research Institute (ITRI), has an extensive set of resources and processes to help local manufacturers doing everything from reclaim waste water to recycling LCDs.

Obviously, all of the efforts in display manufacturing sustainability go beyond TVs – there’s a world of smartphones and laptops and tablets out there. One thing is for sure, that no matter how long TVs last, and there’s some debate about the reliability of some, we are scratching the surface of what can be done to make the circular economy go round and round for displays. In the meantime, we’ll have to wait on RTings to come up with the answer to the question, how long will they last?