Metasurfaces are 100 times thinner than liquid crystal cells, offer a ten-fold increase in resolution, and consume half the power.

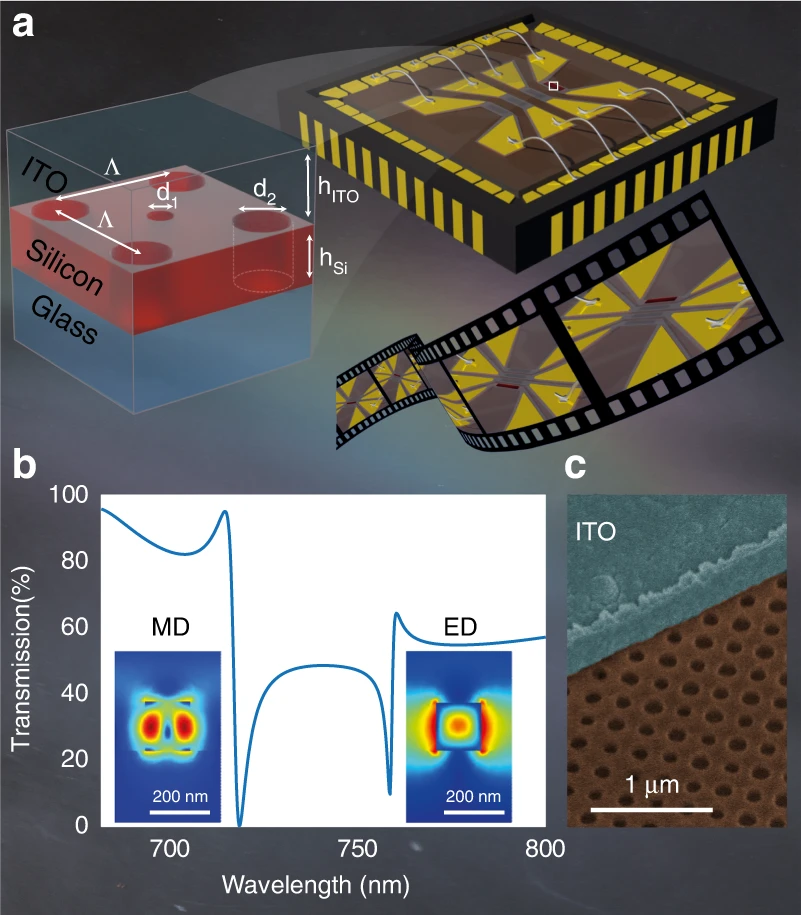

Metasurface technology is a type of engineered material that can control the propagation of electromagnetic waves, including light, in ways that are not possible with traditional materials. It is made up of a planar array of sub-wavelength-sized structures, which can be designed to manipulate the phase, amplitude, polarization, and direction of the electromagnetic waves that interact with them. Metasurfaces can be used to create flat optical components, such as lenses, beam deflectors, and polarizers, that are much thinner and lighter than traditional optics. They can also be used to manipulate the color, intensity, and direction of light in new and exciting ways, making them useful for a wide range of applications in fields such as telecommunications, imaging, and sensing. Researchers from Nottingham Trent University in the UK, the Australian National University (ANU), and the University of New South Wales (UNSW) Canberra have created metasurfaces that performance better than current LEDs and LCDs.

“We have paved the way to break a technology barrier by replacing the liquid crystal layer in current displays with a metasurface, enabling us to make affordable flat screens liquid crystal-free,” lead researcher Mohsen Rahmani, Professor of Engineering at Nottingham Trent University, said. “The most important metrics of flat panel displays are pixel size and resolution, weight and power consumption. We have addressed each of these with our meta-display concept. Most importantly, our new technology can lead to a huge reduction of energy consumption – this is excellent news given the number of monitors and TV sets being used in households and businesses every single day. We believe it is time for LCD and LED displays to be phased out in the same way as former cathode ray tube (CRT) TVs over the past ten to 20 years.”

The new technology exploits the large thermo-optical effect of silicon, which means that the material’s optical properties change when it is heated or cooled. By embedding tiny transparent heaters on the metasurface, the researchers were able to locally heat specific regions of the metasurface and switch its optical properties in response to an applied voltage.

The new technology has several advantages over existing methods of tuning metasurfaces. First, it is very fast, with a modulation time of just 625 microseconds, which is more than 10 times faster than the detection limit of the human eye. Second, it is polarization-independent, meaning it works equally well for light with different polarizations. Third, the metasurfaces are miniaturized and fully solid-state, meaning they can be easily integrated into other devices. Fourth, the tuning can be achieved with very low biased voltages (<5V), making it compatible with standard CMOS electronic devices.

The researchers demonstrate that this technology has important applications in various cutting-edge gadgets, such as flat panel displays, virtual reality dynamic holography, or light detection and ranging (LIDAR). These devices require fast, solid-state, and transparent optical switches, which are precisely what this technology provides.

Dragomir Neshev, Director of the ARC Centre for Excellence in Transformative Meta-Optical Systems (TMOS) and ANU Professor in Physics, said: “The capability of conventional displays has reached its peak and is unlikely to significantly improve in the future due to multiple limitations. Today there is a quest for fully solid-state flat display technology with a high-resolution and fast refresh rate. We have designed and developed metasurface pixels that can be ideal for the next-generation display. Unlike liquid crystals, our pixels do not require polarized lights for functioning, which will halve screens’ energy consumption.”

It’s worth noting that metasurfaces are a relatively new and still-evolving technology, so their performance characteristics and manufacturing costs may change as research continues. Additionally, LCDs and LEDs have a long history of development and refinement, and may also continue to improve over time. However, this is a CMOS-compatible, silicon-based chip, therefore, based on mature and inexpensive technologies. With the addition of AI techniques in future development, the researchers believe that they can achieve even better results.

Reference

Zangeneh Kamali, K., Xu, L., Gagrani, N. et al. Electrically programmable solid-state metasurfaces via flash localised heating. Light Sci Appl 12, 40 (2023). https://doi.org/10.1038/s41377-023-01078-6