On the face of it rollable displays look as though they have a number of key advantages over foldable displays. With foldables, there is a very tight radius at the ‘crease’ area and it would seem as though it would be better to have a more even curvature as you roll a display around some kind of cylinder. Early device ideas tended to show devices like scrolls that started out round, but out of which a display is pulled. There might be devices like that in the future although they will probably need a clever support structure to work well.

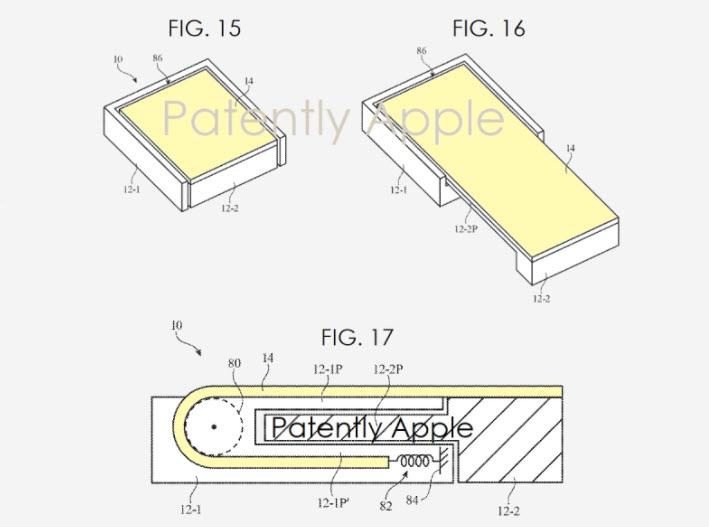

On the other hand, as we have seen with foldable displays, users like to have an ‘always on’ display on their devices that can be viewed without opening the device. With in-folding devices, like Samsung’s Galaxy Z3 Flip and Fold that means a complete second display on the outside. An alternative would be to simply have one side of the display as rollable so that the device could increase in size in one direction. You could roll the display around a cylinder on one side, or in an alternate configuration, you could simply loop it around a roller and store it behind the device. LG raised a lot of expectations by showing a smartphone like this at CES this year. Sadly, however, the firm has dropped out of the smartphone handset business altogether, although LG Display remains in the smartphone display business (along with plenty of other parts of the LG business). Oppo has also shown a prototype concept and Apple has a patent on a rolling mechanism.

So, why have rollables not made it into actual production devices so far? There are a number of reasons.

It’s likely that, like the LG prototype, users would want a motor to automate the unrolling process. This would also have the advantage for the handset maker that they could control the speed and stress on the display as it opened up. Allowing the user to do it manually could lead to too much force being used. However, adding a motor and mechanical support would add complication, weight and bulk and operating the motor would use valuable battery power. Moving parts would also add to potential concerns over reliability.

Stress is Distributed – Good News, but Bad News Too

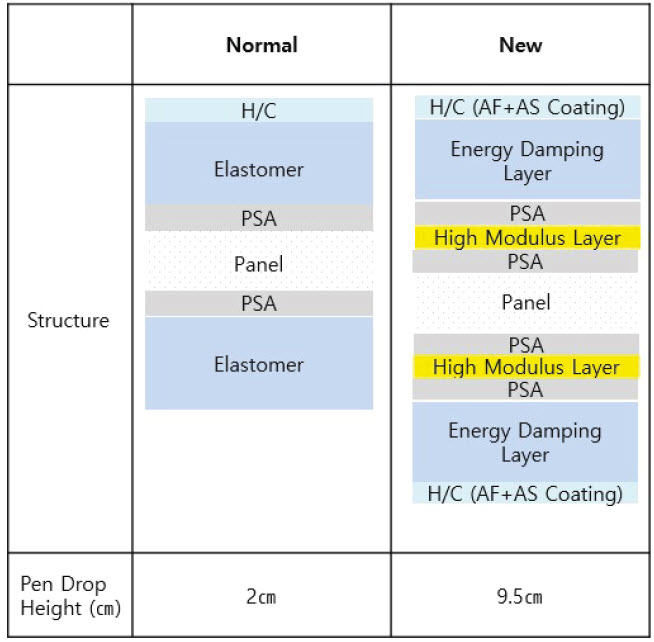

Although the stress would not be concentrated as it is in the crease of folding handsets, a large area of the display would need to be capable of standing a lower level of stress. DSCC’s Ross Young has pointed out that this could be a particular challenge for polariser layers. Another issue is that the inside and outside surfaces bend by different amounts. The display is composed of lots of layers that are typically separated by pressure sensitive adhesive and these layers are subject to a lot of strain during rolling – much more than a foldable display according to a paper by Samsung Display that was published at the SID Display Week this year¹ Because of the stresses and strains, it is hard to get a display that has been rolled up to return to its original flat state after rolling, as there is some ‘creep’ between the layers. There can also be damage from electrostatic forces created by the movement of the layers (like rubbing a balloon on a jumper), although this can be mitigated by anti-static treatment.

Rolling the display tightly (R5) moves the position of the maximum strain from the centre of the display towards the start end (that is attached to the roller).

A nicely flexible display panel needs restorable and resilient elastomer materials. Unfortunately, they may not be hard enough to resist the critical ‘pen drop’ test. To offset this potential damage, Samsung proposed a more robust structure, but you can see how much more complicated it is. Samsung tested the structure after 20,000 rolling operations at R10 and found it was robust. The firm made a 12.4″ rollable display to demonstrate the idea. R10 suggests a big device thickness, however, so smartphones wouldn’t be in the frame. Nobody would go back to smartphones of over 20mm thickness, although the firm sees applications in pull-out displays from smart speakers.

Samsung showed the pen drop height could be improved, but at the expense of more complexity.

Samsung showed the pen drop height could be improved, but at the expense of more complexity.

There are also other challenges. There needs to be a big aperture for the display to go through into the casing. That will provide particular challenges in waterproofing and small particles caught in the aperture might scratch the display as it goes in and out. Also, the ‘always on’ display will be the flexible one that is on the outside. In that position, it will not be protected and is likely to be more easily scratched and damaged than in-folding designs.

Balancing these challenges, a rolling phone might be thinner than a foldable and although there might be wrinkles from the rolling, they will be most visible along the edges of the display protector and the edges could be hidden under the frame.

So, all things considered, rollable smartphones are likely to make an appearance and DSCC has said that it expects a rollable device from Samsung in Q1 2023. (BR)

¹ Paper 68.1 Extremely Robust Rollable AMOLED Display