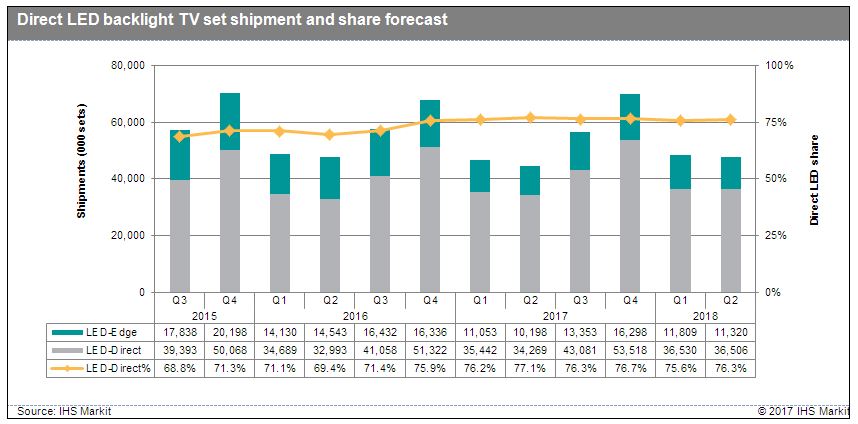

In a blog post, David Hsieh Research & Analysis Director within the IHS Technology Group at IHS Markit has pointed out that direct lit architectures dominate the TV LCD panel market, hitting a peak in Q2 2017, but with the firm expecting similar penetration as we go into 2018. The direct-lit panels (where LEDs are directly behind the cell) use fewer LEDs than edge-lit panels, and do not require Light Guide Plates. However, they are thicker than the slim sizes possible with edge LEDs.

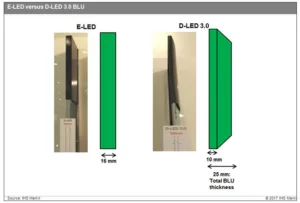

The thickness of direct-lit LCDs has been reducing, with optical distance (OD – the distance from the LED to the diffuser) going from 25mm to 50mm in the past to 15-18mm now. The latest technology has an OD of 10mm, giving a total module thickness of just 25mm.

Direct-lit modules have the advantage that they can support HDR by backlight modulation. Although there can be some large area modulation in edge-lit panels, HDR cannot be supported.

As the market develops, the number of LEDs is going up to give better control and uniformity.

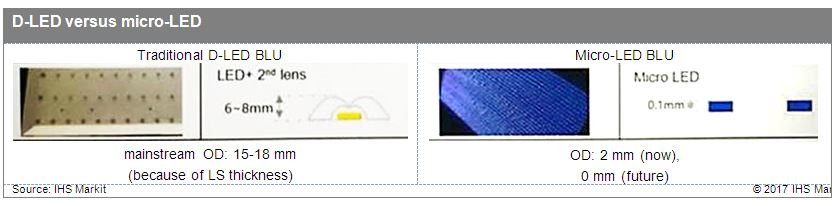

Taking this further, LCD makers are investigating the use of microLEDs in backlights as it will be hard for direct MicroLED to compete with LCD and OLED in the short term, especially with the development of 8K. The use of microLED backlights could both improve panel performance and reduce the thickness of LCDs in the size range from 65″ to 80″. MicroLEDs would not be used with lenses, which typically may be 6-8mm deep, and the LEDs themselves are just 0.1mm thick, so there is a belief that the entire backlight module could be as thin as 10mm.

The secondary advantage is in the boost in the number of local zones for HDR, which should reduce haloing effects and give better uniformity. Finally, Hsieh said, MicroLEDs made with flip-chip-on-module technology might be cheaper than traditional LEDs. Hsieh also pointed out the following additional issues:

- Micro-LED technology requires the use of more LED chips, translating into higher power consumption. While a 75-inch 8K television may need 1,000 direct LED chips as the light source, at least 70,000 chips would be needed in micro-LED, with power consumption 1.5 times greater than that used by direct LED backlighting.

- Given the high number of micro-LED chips that must be installed on the back of panels, heat dissipation will be critical.

- Although not a major issue when it comes to color binning—as micro-LEDs for backlighting are white in color and therefore have no color function—luminance uniformity could still be affected. Color binning is the process in which LEDs are tested and sorted.

- The key technology for producing micro-LEDs is the transfer method, in which equipment constraints and an immature process are known limitations. Production time for micro-LED could be 10 times longer than that for a direct LED, raising costs as a result. And because the technology is comparatively new, overall reliability remains to be proven.

Analyst Comment

As Ken said in his Display Daily, Samsung had some very impressive direct lit sets in its closed innovation zone at CES and which will be in high end sets later this year. I thought that the performance was probably only the second LCD that I had ever seen that could look better, when side by side with an OLED. (BR)