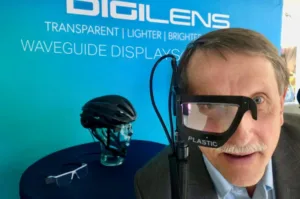

One of the more important developments that will be revealed at the 2019 SID Display Week event will come from DigiLens, a California-based company focused on waveguide technology for AR/VR and Head-up Display (HUD) applications. And what did they reveal: the worlds first plastic waveguide offering a full color image in an AR eyeglasses-type demonstrator.

I had a chance to take a look at the innovation on a visit to the company just prior to SID. While the image quality is still not perfect, it is the first prototype of this kind and I have no doubt the company will get to much improved image quality in short order.

Why is a plastic waveguide so important? “Weight, ruggedness, cost and compatibility with plastic optics are all compelling benefits for the technology,” said Dr. Jonathan Waldern, founder and chief technology officer for DigiLens. He explained that diffractive waveguides used in AR headsets are generally fabricated on high-quality glass substrates using a complicated silicon wafer type manufacturing process. The Microsoft HoloLens, and Magic Leap AR headsets use such glass-based waveguides and cost north of $2K. Waldern thinks their waveguide fabrication processes coupled with the plastic substrates can dramatically lower the cost of the waveguide component – and they will be nearly unbreakable. OEM’s are incorporating DigiLens waveguides and plan to offer a monocular AR eyeglass attached to a smartphone later this year in the $500 price range – probably a new low for a waveguide-based product.

Waldern said he believes this breakthrough technology could drive costs down and adoption up across a myriad of augmented reality display applications, including car HUD’s, motorcycle helmet visors, ski googles, smart glasses, prescription eyeglasses and, of course, gaming headwear.

What is also really exciting about the plastic waveguide is the ability to offer AR glasses that also include a user’s prescription. Low cost plastic optics, typically used in eyeglasses today, can now be cost effectively bonded to the plastic waveguide for customize AR eyewear.

While the waveguide is made of plastic, it is not flexible, but rigid. Its development is the result of a partnership with Mitsubishi Chemical Corporation. Development has been on-going for the last five month following participation in Series C round of funding by Diamond Edge Ventures, the venture capital arm of Mitsubishi Chemical Holdings Corporation, formed last year.

Mitsubishi Chemical got involved in the project because it is a leading producer of advanced plastic materials, and a supplier to the optical industry. Diamond Edge Ventures had been looking for a first project that would building on the company’s materials legacy and enable it to become an “active participant” in AR and VR. Patrick Suel, president of Diamond Edge Ventures, thinks the new plastic waveguide is a “significant development in the evolution of material science and engineering.”

According to the companies, the injection mold planarity and custom functional coatings needed for this technology can be configured with either all-plastic or hybrid plastic-glass optical waveguides. DigiLens says the biggest breakthrough, though, is that it was able to produce a design for plastic lenses that would approach the crystal-clear clarity, brightness and color of precision glass. That certainly seems to be the case as the prototype I observed had incredible transparency and the waveguide components were nearly invisible, which was very encouraging.

DigiLens employs a licensing business model whereby its technology and manufacturing knowhow can be transferred to a licensee to do in-house or merchant production. This model has already been used to set up production capabilities with Continental (auto HUDs), Collins Aerospace (avionic HUDs) and Young Optics (mobile HUD and AR eyewear). Waldern was quick to point out that, “This new plastic waveguide is really a big deal,” said Waldern. “Our photocopy process basically allows companies that license it, to now leap-frog their competition very quickly.”

Waldern then claimed that Apple is thought to be developing a similar manufacturing approach to DigiLens for use in HUDs, including its long-rumored but un-announced Apple AR Glasses, but he did not think they yet had the plastic waveguide capability. Apple has created an ARKit platform to encourage developers to write AR programs for iOS devices, which can then theoretically transition to use on an Apple AR headset.

For their part, neither DigiLens nor Mitsubishi Chemical pulged whether they have any AR equipment manufacturers signed up to make products based on their plastic specification. But Waldern said he’s heard enough from current and prospective customers to suggest there will be plenty of interest.

“We’ve already proven with our AR motorcycle helmet HUD that we can deliver holographic waveguide displays small enough for use in motorcycle and bicycle helmets,” he said in reference to a design showcased with BMW Motorrad. “Now, with this plastic material, which we developed with Mitsubishi Chemical, we think we’ll see significant pickup in a range of industries and a wide variety of AR applications. It could even become relevant for things like the upcoming Google Maps AR feature. The possibilities are endless.”