Crystalplex Corp. announced that it has been awarded US Patent No. 9,425,253, “Passivated Nanoparticles,”. The patent, which claims the fabrication and use of Sapphire quantum dots, or passivated quantum dots with improved stability, was granted to inventors Lianhua Qu and Gregory Miller.

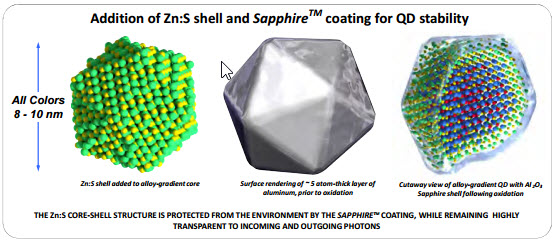

The patent is directed to processes for synthesizing an alloy gradient nanoparticle with a Zn:S shell and an outside coating of aluminum oxide that provides a barrier to environmental degradation. In addition to providing improved photo, thermal, and environmental stability, the quantum dots demonstrate longer lifetimes, as the optically transparent aluminum oxide outer layer serves as a shield against degradation by humidity and oxygen. The passivation technology is applicable to Crystalplex’s alloy gradient cadmium-free quantum dots, as well.

“The protection provided by the Sapphire quantum dot shell makes passivated nanoparticles particularly well suited to the demanding requirements of optoelectronic applications,” said Dr. Qu, Chief Technical Officer at Crystalplex Corp. “They have proven to be quite resilient.” In August, Dr. Qu presented his findings on the use of passivated quantum dots in a thermally processable matrix at the 26th International Liquid Crystal Conference (ILCC) at Kent State University in Ohio. (See Dr. Qu’s technical paper www.crystalplex.com and click on Technological Developments)

“The granting of the passivation patent further strengthens our robust patent portfolio,” said Crystalplex CEO Matt Bootman. In addition, these air-stable quantum dots have been melt processed in polymer substrates. To our knowledge no other manufacturer’s quantum dots can withstand such extreme heat.”

Crystalplex Corp. is a private firm with 12 years of R&D directed to quantum dot technology. The company maintains a fully integrated synthesis and pilot application plant in Pittsburgh, PA, USA.

For more information about Crystalplex Corp.: www.crystalplex.com

Source: Crystalplex

Source: Crystalplex

Analyst Comment

Crystalplex said that it has a video of quantum dot/polymer composite being co-extruded with PMMA at over 200°C, but the link was wrong, and we hadn’t got a good link at press time.

The development of air-processable quantum dot materials is an important one as it potentially allows the replacement of the colour filter by a colour conversion layer. Crystalplex is, as far as I am aware, the second company to publicly say it can make them, after Nanosys.

In the case of LCDs, if you can put the QDs in inks for inkjet printing or materials for photolithography (neither trivial challenges), you can use QDs in the same processes currently used for making filters. For LCD makers it means having to put the polarising layer inside the LCD cell (as the light being converted would lose its polarisation, so you need to put the analysing polariser before the QD layer), and this is an engineering problem but not a problem of the basic physics.

In large OLED manufacture in the method used by LG, if you could change the colour of the OLED layer to simply blue, and replace the filter with a conversion layer, what looked like a ‘bodge’ that Kodak invented to get around the problem that it simply couldn’t pattern large RGB OLEDs (the same problem that Samsung had) suddenly looks a very clever and efficient architecture! (BR)