It has been a few years since Corning announced a new glass type for the display industry, This is changing this year with the announcement of Astra, a new glass type for the LCD and OLED industry.

For many years, display glass has been dominated by glass specifically designed for amorphous Si – TFT LCD panels. As an alternative LTPS panels became more common in high end mobile applications. With the much higher electron mobility achieved by the LTPS-based TFT back panels, mobile displays achieved a much higher display performance. Since it is difficult to apply the LTPS process to a large panel and also more costly, TVs are still dominated by amorphous Si. With the advent of OLED technology entering the TV market and the move to higher pixel counts at higher frame rates, faster switching TFT backplanes are required.

Corning Astra glass for high end TVs; credit: Corning

Corning Astra glass for high end TVs; credit: Corning

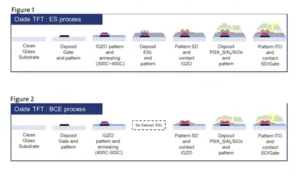

According to Han Yim, Business Director of Corning’s High Performance Display Division, these requirements can be fulfilled through the deployment of oxide TFT technology. The most common form of this technology is IGZO (Indium Gallium Zinc Oxide) technology. While IGZO does not reach the same electron mobility as LTPS, it is still much better than a-Si by a factor of ten at least. On the positive side, IGZO is applicable also to substrates up to Gen 10.5. On the negative side oxide TFT reliability questions led to the need for an ESL (etch stop) process, which includes a process requiring an additional patterning step, thus making the production more complicated and costly

The BCE (back channel etch) process is quite similar but eliminates one patterning step making the overall process complexity comparable with the a-Si process. On the negative side the BCE process requires a high temperature annealing step reaching 400°C – 500°C. In this temperature range existing backplane glass compositions tend to reach their stability limits by becoming too soft. This is where the new Astra glass from Corning comes in.

Oxide TFT processes; Credit: Corning

The challenges for backplane glass are to minimize elastic distortion caused by the applied film stresses. This happens in annealing steps at temperatures in the range of 400°C. A high viscosity of the glass composition at these temperatures is required to avoid deformation. At the same time it is also required to minimize compaction or shrinkage at these annealing temperatures, which requires a sufficiently high viscosity of the backplane glass.

Besides the high temperature characteristics, the glass plate has also to achieve a very low total thickness deviation and waviness, which is achieved by Corning’s fusion process. There are many more physical and chemical attributes that make a glass a good backplate material. In a new glass type you have to optimize all these properties while increasing the viscosity at high temperatures. For your understanding, this means that the glass has to be produced at much higher glass forming temperatures as the forming step requires a certain low viscosity to make the glass flow easily.

Astra glass is an alkaline earth boro aluminosilicate glass type similar to the the existing EAGLE XG type, but raises the working point (defined as the temperature where the glass reaches a viscosity of 107.6 poises) from 971°C for Eagle XG to 1013°C for Astra. The temperature increase for Astra is about 42°C at the working point and increases to 56°C at the strain point (1014.5 poises). The composition also manages to increase the Young’s modulus from 74GPa for the Eagle XG glass to 81GPa for Astra. All in all, Astra is a glass that takes a higher temperature load without deformation which is just what the IGZO BCE process requires.

Astra is available now for Gen 7.5 to 8.5 with support for Gen 10.5 the future. The thickness ranges from 0.5mm down to 0.25mm, which is still too thick for mobile applications, even though Astra glass offers the same advantages for mobile devices as it does for TVs. While mobile displays are made on Gen 6 lines instead of Gen 10.5, the glass is still too thick for today’s smartphone requirements and are etched down to thinner thicknesses. Astra glass is also optimized for faster etch rates with minimum sludge creation. That makes it an optimal candidate for mobile displays as well.

All of this assures Corning that Astra will be a major step forward for the display industry and provides them with an industry leading glass material. -NH