A couple of separate press releases related to the same topic popped into my inbox this week and gave me a good theme for my Display Daily today. That topic is screen glare or reflections from displays.

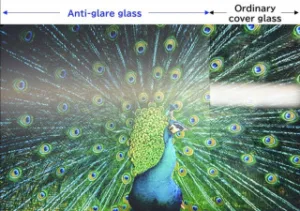

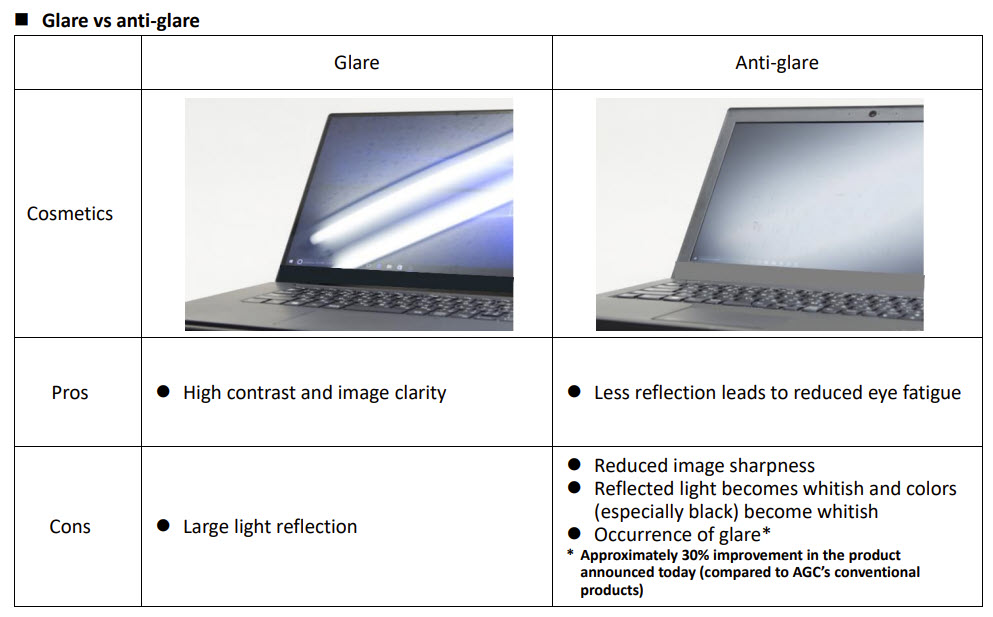

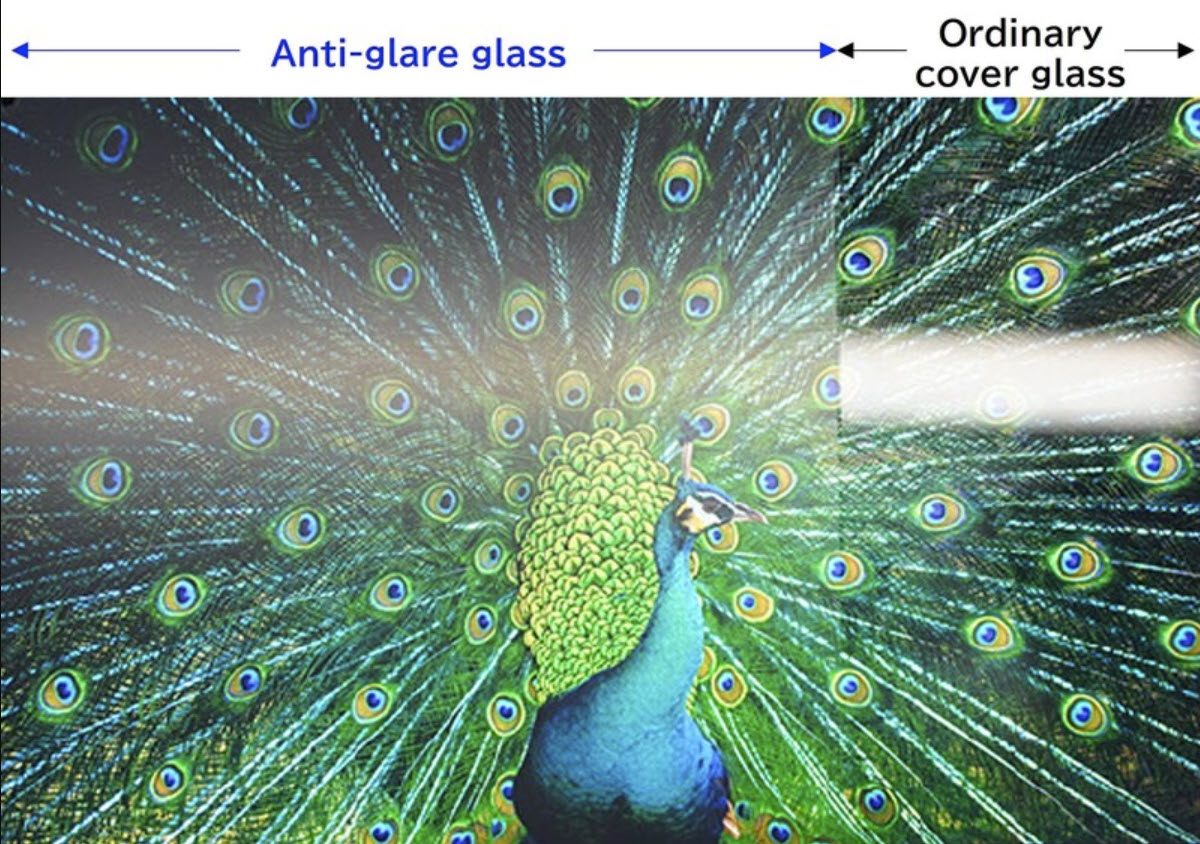

First, glass maker AGC of Japan said that it has developed a new anti-glare glass for 4K high definition displays that reduces glare on displays by 30% while reducing light reflections.

Reflections Have Always Been a Challenge

Glass front surfaces have always been a challenge for display makers – and I learned about them four decades ago when I first got professionally involved with displays. Light reflects back off shiny glass surfaces, which is distracting. However, shiny glass surfaces allow the light going through the glass to pass very cleanly, so they tend to make the image look much sharper and crisper. In an ideal world, you would find a way to stop the reflections, but keep the surface flat. But for office work, especially, you have to eliminate reflections as much as possible.

In my early days, I first came across etched glass surfaces. This process simply roughened the surface of the glass causing the light to be reflected in different directions and reducing the reflections back into the eye. However, they were difficult to control and sometimes resulted in a kind of granular, ‘sugary’ look to the displays as the pattern in the glass reacted with the pattern in the pixels.

A Good Solution

The best way to solve the problem was to use the kind of three very thin layers of metallic compounds that were just a quarter wavelength (?/4) thick that are used to multicoat lenses. Each layer blocks one colour. The layers cause the light to be out of phase when being reflected and achieve cancellation (let’s ignore quantum mechanics for now!), eliminating very nearly all of the reflections, but without distorting the light coming through the panel. They gave an excellent result, but the process of depositing the layers was tricky, especially as most monitors were spherical on the front. The layers are also prone to troubles with fingerprints as the oil from the finger is thick enough to make a difference to the thickness of the layers and have an optical effect.

Typically, the anti-reflective coatings were put onto a separate panel and then this was bonded onto the front of the CRT using an optically compensated adhesive between the panel and the tube, to avoid internal reflections. Sadly that was expensive, but it’s one of the reasons that Sony’s Trinitron CRTs had such a good reputation in the workstation market as they had that kind of technology.

Other Coatings

To do something better than etching, but cheaper than AR panels, companies developed coatings (silica was often used) that could be applied to the tube to roughen the surface in a more predictable and even way than etching. They were applied to tubes directly, but could also be put on films. Unfortunately, the films were hard to apply to spherical surfaces, but not so hard for Sony’s Trinitron or the derivative Mitsubishi Diamondtron CRTs which had a cylindrical face (or Zenith’s FTM CRTs which were completely flat). I remember hearing, second hand, that at one time Nokia, which used to have a high end monitor business, was buying Trinitron CRTs from Sony in Japan and having them shipped via the US to have optical films attached before building them into monitors in Europe.

Of course, flat panel displays made things a lot simpler with respect to shape!

Finer & Finer Patterns

The idea of finer and better patterns to reduce glare and reflections was further developed and Sharp was, I think, the first to apply what it called a ‘moth eye’ pattern. This kind of micro-pattern imitated the way the eye of a moth works and was very very good at suppressing reflections. Unfortunately, it seems to have been expensive to produce and disappeared from that firm’s range. I dug into moth eye approaches after SID this year (Reflections on Display Week) and in recent years, I think it is Samsung that has most impressed me with its anti-glare technology for TVs.

The interesting point about the AGC announcement is that the new approach is said to be enabled by a ‘special mechanical process’. That, it seems to me, ought to make it cheaper than adding a special microstructure film. Making the technique cheaper is critical in getting wider adoption and should also eliminate the addition of an extra film which is always an advantage.

Second Announcement – We Love Glare!

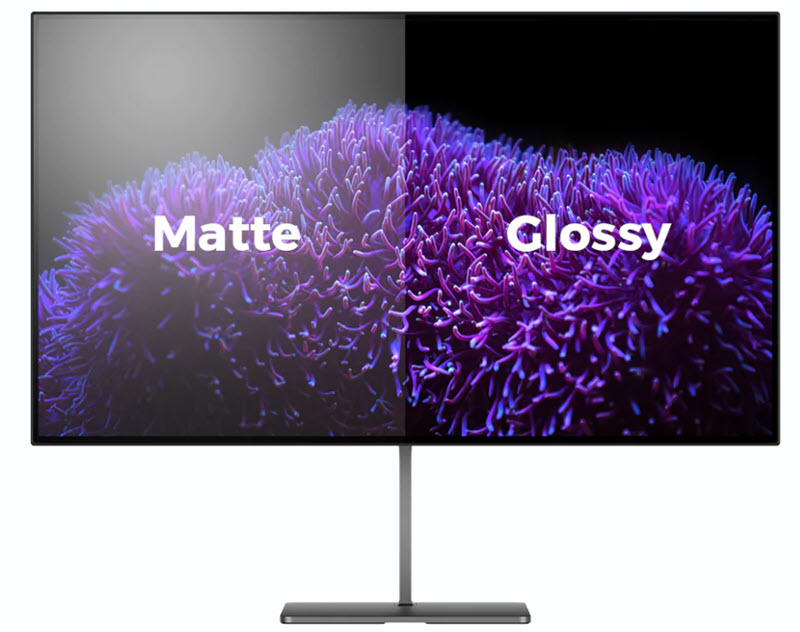

Anyway, the second announcement was from a ‘crowd-developed’ monitor from Dough Spectrum which is developing a 27″ glossy OLED monitor. This uses a glossy polariser to minimise the effect of any anti-glare treatment and deliver the crispest possibly image quality. The monitor is said to have a low-haze anti-reflective coating and is a QuadHD unit with 150cd/m² typical/1,000 cd/m² peak output and up to 240Hz, using a WOLED panel (which will be from LG Display – editor). It is certified to DisplayHDR 400 True Black and has 98.5% of DCI-P3 coverage. It will sell for $649 for pre-orders, but won’t ship until July.

This decision to ignore glare reminded me of a change in notebooks in Europe some years ago. One of the notebook brands decided to put a glare display on one of its consumer notebooks (commercial use of glare displays is not allowed under the EU Display Screen Directive). The notebook stood out in store and gained good sales, so rapidly other brands switched. However, over time they all switched back to non-glare as being better for the user. (Writing this made me realise that it’s a while since I did a store visit to have a look at this kind of topic – Editor)

Personally, although I love the punch of glare displays for a minute or two, but I certainly wouldn’t buy one for long term use! (BR)