A few days ago Ceres Holographics, the Scotland-based developer of holographic optical elements (HOE), announced that it has reached the next stage of development with a new machine that can bring production for automotive HUDs closer, so we took the chance to catch up with Andy Travers, CEO of the firm, to get more information.

I have previously met with the company at CES (remember when that was an actual event?) when it showed its technology and I was impressed by how good it looked. Let’s cover the basics.

This is not the best ever photo, but is an actual image of the Ceres technology that I captured at CES in 2020. Image:Meko

This is not the best ever photo, but is an actual image of the Ceres technology that I captured at CES in 2020. Image:Meko

Ceres has developed a way of designing the holographic elements that can be structured into a film at 16 per mm² and that can be laminated into a windscreen. The elements are wavelength sensitive and if light of the chosen wavelength hits the film, the light can be guided in a range of ways. In a windscreen, the light is reflected back to the driver (although it could be, for example, directed at a passenger). If the light is of another wavelength it simply passes through, so the film is highly transparent (up to 99%, Travers told us and, of course, the degree of transparency of windscreens has legal requirements that have to be met – a challenge for non-projection technologies).

From a display device point of view, it doesn’t really matter what the display device is, but Travers and his firm are working closely with TI which has devoted a lot of time and attention to automotive HUD applications and has qualified systems to provide the optics. He was very positive about the collaboration with the DLP maker. The DLP has particular advantages it extreme temperatures and TI’s designs for projection engines have well engineered solutions for projector alignment, which is critically important to ensure the correct eyebox.

Eyebox size is a challenge for HUDs because of the extreme range of human size and driving positions, unlike an AR/VR system which fix the display relative to the face. TI has also done a lot to work on the other challenge of HUDs – the volume taken up by the projection engine.

The new machine to make ‘master stamps’

The new machine that the company has acquired can make patterned areas of ‘just above A3’ at around 300 x 400mm (12″ x 16″). The limit of the size is just a limit of the machine – there is no theoretical limit to the size of the area. The machine will be used by Ceres to make ‘master stampers’. These masters can then be used to create further ‘production masters’. It’s a bit like making a vinyl record. First you make the master and then you create moulds for volume production. Part of Ceres’ ‘secret sauce’ is that it knows exactly how to create the master so that the production patterns work correctly.

The firm’s business model is based on NRE charges for design creation, sale of the master masks and with licences for production pattern creation and finally a licence fee for windshields. The company plans to supply those that make the windshields and their materials. Travers told us that a ‘typical windscreen’ costs around €60 before adding the safety interlayers etc. In an ideal world, makers would have the HUD layer in every windscreen as it makes warranty and production so much simpler, but to be standard, the added cost of the system has to be as low as possible. The idea is that the photopolymer (supplied by Covestro) is applied over the whole windscreen as part of the interlayers. Just the area where the HUD image is desired would be patterned, so the size of A3-ish is plenty at the moment.

Getting the HOE pattern film and element adopted as standard for particular models would be a real advantage. In the past, I have spoken about this with General Motors who told me they believed that, in time, the HUD would be the only display for controlling the car. However, the firm admitted that it would take years for the idea to be accepted by drivers, although those that got used to a HUD hated to go back to a car without. Ideally, you would equip all cars with HUDs, then gradually limit the dashboard functions until they disappeared. To do that, you have to make the HUD as low cost as possible.

At the moment, as Travers pointed out, HUDs are far from ubiquitous and are often part of a high cost ‘multimedia package’, which limits the numbers sold.

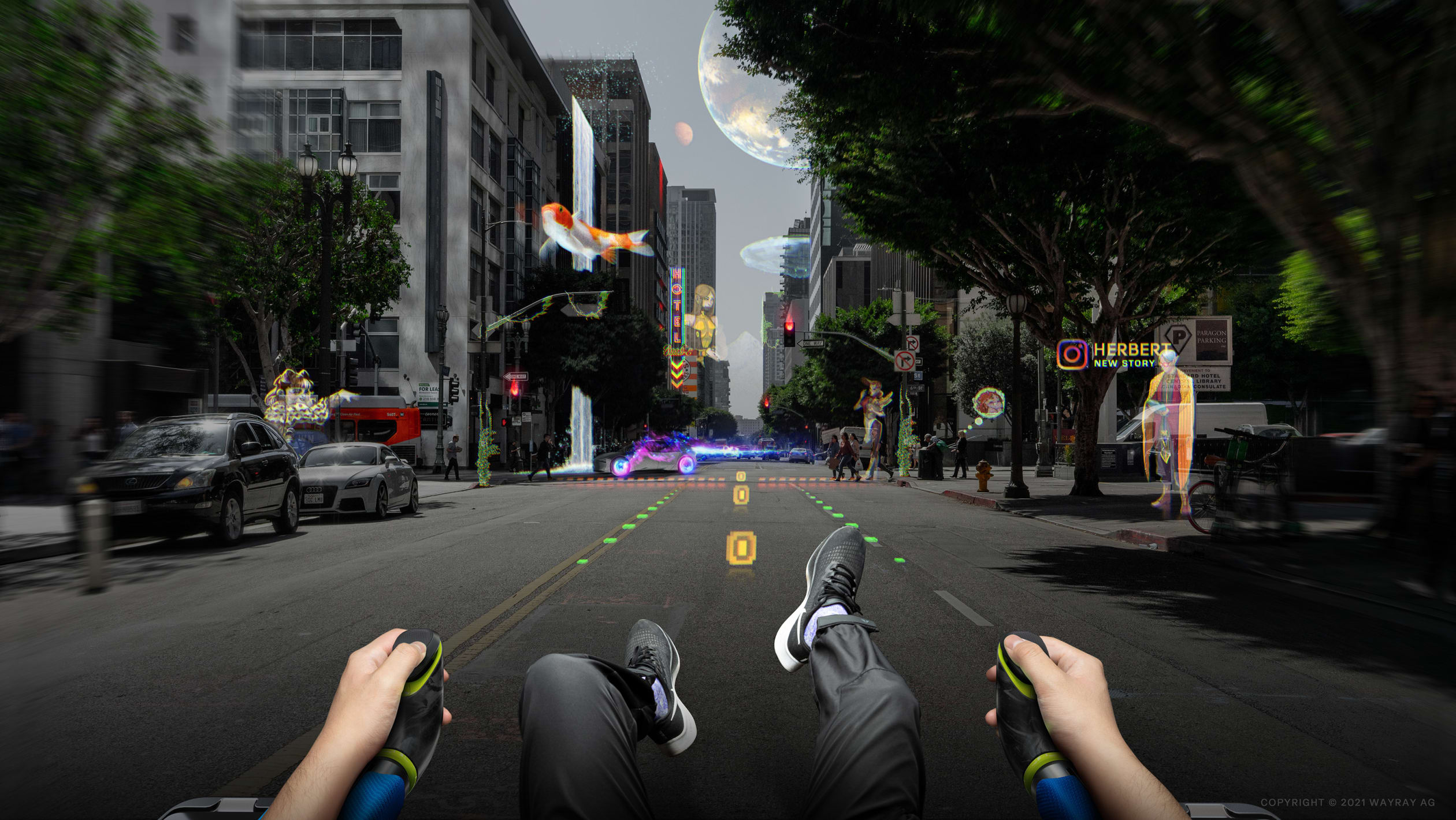

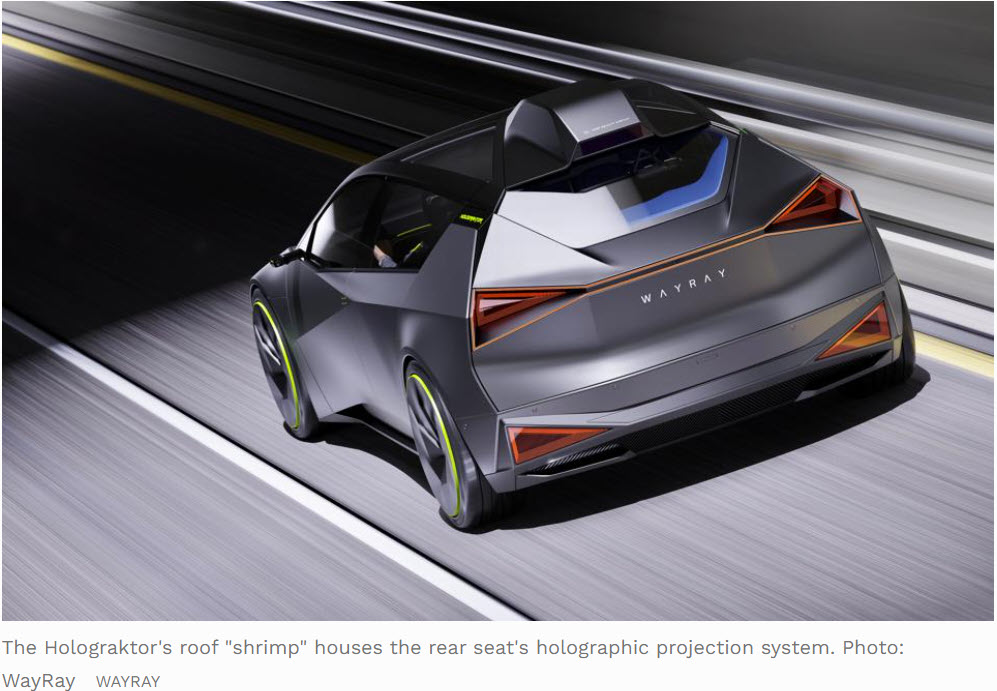

By chance, a couple of days after I spoke to Travers, I spotted the Holograktor concept car from Wayray. One of the features is a kind of pod that could be in the roof of the car and could hold projectors that show images on the rear windows. In this kind of case, the pattern would be over the whole of the window and could be enabled by technology like the Ceres film. (BR)