One hot topic that we have been following over the years is flexible displays. The topic is of course related to the advent of OLED displays challenging LCD screens as the display of choice for mobile devices.

For sure everyone has seen the following image (or one just like it) where we were promised a fully flexible display from the roll, all that was left to do was to package this in some form of flexible container and we have flexible devices. It may surprise you that this image was published in early 2009 and now, eight and half years later, we are still not anywhere closer to a fully flexible device than we were almost a decade ago.

Flexible Display – Published by the The Economist in 2009

Flexible Display – Published by the The Economist in 2009

One may say ‘good things take time’, but we don’t really know if a flexible mobile device is actually a good thing nor do we show any patience when to comes to technology development in the display world. In the same time frame, OLED displays have moved on their way to become the dominant display technology by 2020 (as IHS Markit is predicting) but flexible displays are not really on the horizon, for now. There are some devices available that use shaped displays, meaning their flexibility is being used once in one direction.

So what is the hurdle here? Is it more difficult than expected to make flexible displays or is the real issue with the flexibility of all components? A flexible display screen with a rigid PCB and battery does not make much sense, or does it? I think that the reality lies not with one answer but with all of them. It turns out that making flexible display screens is actually well in the realm of technical possibility, while flexible PCBs and flexible batteries prove to be a little more difficult to achieve. While printed electronics on flexible plastic substrates do exist, their performance does not even come close to that of today’s PCBs used in mobile devices (and they are themselves moving to higher technologies – Man. Ed.). The demand for high computing power has grown dramatically faster than the improvements in flexible electronics through R&D.

When the leading smartphone brands fight on the level of computing power for video editing on your phone for example, waiting for a flexible PCB that can support that is just not on the cards. This does not even include a flexible processor for example.

At the same time flexible batteries are also being researched and some results are promising, but we are still far away from going to your closest electronics store and picking one up any time soon. Researchers are still evaluating different types of rechargeable technologies as they are not sure what type may be the best solution, going forward. If you are familiar with university-driven research today, R&D is not a self contained entity that looks at research from a pure science perspective. Instead application driven research has a higher chance of producing patents that can be licensed to technology and manufacturing companies, and that is a major source of funding for the universities.

A recent publication from the Shanghai Jiao Tong University group of Xu Chen et al about the development of high performance electrodes for Zn – Air batteries demonstrates this very well. This program goes back to a contract awarded by DOE to Argonne National Laboratory in 2006 with an expiration date of 2026! It seems they did not really expect any form of immediate success that would be needed for the release of flexible devices any time soon. Of course this is not the only government agency awarding contracts for flexible batteries, nor is Zn – Air the only battery technology supported in such contracts.

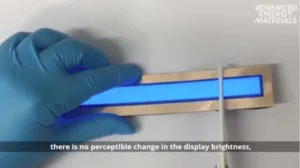

The reason this publication caught my eye is the fact that the developed electrode for the battery that is possibly attached to the backside of a flexible display panel as is demonstrated in a video published by Advanced Science News. While the ‘display’ is more of OLED light source, the fact that they cut into the device with a pair of scissors and the device still functions is pretty impressive. As it seems the researchers are using a copper foil as the backside electrode and I wonder if the ‘display’ will also work when it is cut into two parts? This would give the term screen sharing a complete new meaning!

Flexible ‘display’ electrodes still functioning after damage

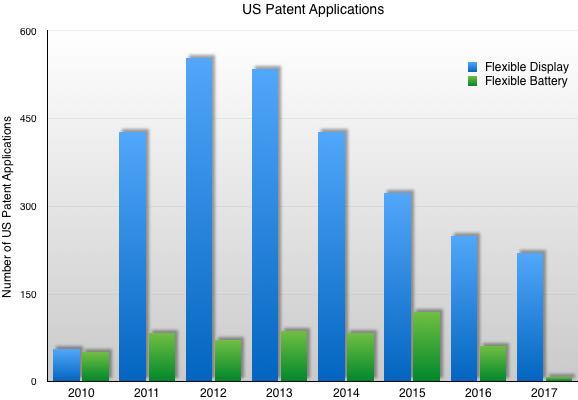

The remaining question is when we will actually see flexible devices in the field? Mounting a flexible display behind a strengthened glass panel does not count in my opinion. One way to judge where we are standing today is to look at the amount of research going into these particular fields. A way to measure this is to look at the number of patent applications that each topic creates. This is no easy feat as one would have to read every patent application published to judge its relevance. An easy way around this complete information overload is to use the use of buzzwords in the patent applications. This is exactly what the following chart shows.

US patent applications using the terms ‘flexible display’ and ‘flexible battery’ in the abstract.

US patent applications using the terms ‘flexible display’ and ‘flexible battery’ in the abstract.

There are two things we can learn from the graph. First, the research activity is much larger for flexible displays than for flexible batteries. Secondly, the height of research activity seems to have been reached and already passed for both topics. Interestingly the height of research for flexible batteries was a few years after flexible displays reached their peak. Do not forget that we are still in 2017, so the number of patent applications is likely to rise for this year.

Flexible displays for flexible devices seemed such a straight forward idea for the proponents of OLED displays. As it turns out, while slightly bendable displays can be achieved in manufacturing quantities and consumer quality today, really flexible displays are something else altogether. Today’s flexible displays are best described as rollable displays. They can be rolled up in direction or the other, but never at the same time. This form of really flexible displays requires some form of stretchable displays similar to a fabric that remains intact even if its original shape is distorted*. Try doing that to a flexible OLED.

The answer to this problem may come from micro LED displays that combine very small light emitting dots with a lot of empty space that can be made up by some form of stretchable carrier. This carrier could be like a woven fabric that uses distinct wires connecting the pixels to the controller and power source. This would require a rethink of the drive schematic among a lot of other things. That’s definitely a topic that we can write about for years to come. (NH)

* Samsung Display showed a genuinely stretchable display at the SID Display Week Event this year.