Ivan Wu is from AUO and he talked about curved LCD. He compared LCD to OLED in cost, performance, reliability, curved an multi-function. LCD increasingly can challenge OLED in performance. He identified that there are three stages of flex; fixed curve (e.g. monitors & TVs); flexible; and rollable. Of course, LCDs are generally made of glass and where the bend radius is >100mm, then glass is OK for curved applications. However, if the radius is <100mm, then you need plastic substrates.

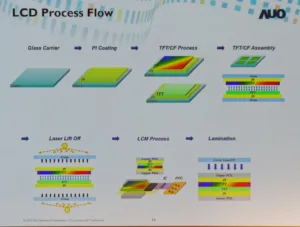

In its testing of glass flexing, AUO found that the edges of the glass are the key weak point for bending glass. Turning to plastic, AUO tested polyimide (PI) which is used coated on glass to make LCDs. He showed the process flow for the LCD processing of PI LCDs. The LCD is made using plastic fixed to glass for processing and then removed after manufacture, using lasers.

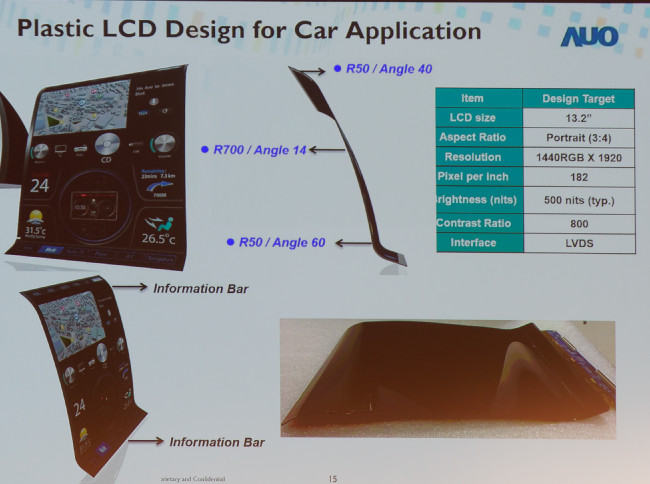

AUO is trying to design an IPS platic ‘design’ LCD for automotive in the future as in this application, designers are looking to get away from flat rectangles. LCD has advantages over OLED in automotive, but needs this flexibility to respond to competition.

AUO is developing flexible LCDs for automotive applications.

AUO is developing flexible LCDs for automotive applications.

Analyst Comment

We were a little disappointed that Wu did not go into more detail about what AUO is doing to revise the design of LCD cells to improve their performance when flexed as we have heard that some good technology is being developed. (BR)