AR is finally arriving, but future growth needs more development. Bay Area SID’s one-day AR/VR conference “Seeing Is Believing” in November gave a glimpse of the current state of the technology and requirements for future development. Seeing display-based AR glasses being sported by some speakers and even some attendees, one could conclude, “AR has arrived”.

As the keynote speaker Jason Hartlove, VP, Optics, Photonics, display and imaging of Meta Reality Labs said, “AR may finally be arriving. Today’s AR display systems are highly complex. Once they reach scale, they will be hard to displace. There are many opportunities for innovation”. Meta officially launched its first pair of AR smart glasses, the “Ray-Ban Meta Display” at its Meta Connect event in September this year. As Jason Hartlove pointed out, “We are in a new era. AI changes the way we interact with information and data. It will demand a new way in which we interact as well. AR is very well poised to be that new way we interact”. Some AI capabilities are already possible with AR glasses such as real-time subtitles and other features such as being a guide for individuals with visual or hearing challenges. He concluded “AR has the opportunity to be the next communication device. The display is a critical accessibility feature; it will create a world that was not possible before.”

Need for Technology Breakthrough & Lower Cost Manufacturing

Ludovic Godet, Managing Director, Head of R&D and Engineering Photonics Platforms Business from Applied Materials focused on the “Photonics platform for invisible AI eyewear”. He presented that mainstream smart glasses require breakthrough display plus breakthrough UX. Consumers expect premium performance displays in an eyewear form factor. He emphasized the need for breakthrough in waveguide display technology, scalable + low-cost manufacturing strategy, co-optimize eyewear design with partners, and personalized eyewear with invisible technology. Display requirements to enable brand-worthy smart glasses are:

- Great cosmetics (frame design)

- Rainbow-free

- High brightness plus beautiful image quality

- Mass manufacturing capability

Applied Materials has jointly developed a system that integrates Applied’s 3.4-gram etched waveguide with integrated lenses, with Avegant’s AG-20 co-optimized light engine into a lightweight and compact MCU-based processing platform. It has completed a prototype of a 43g wireless AR glasses with a monocular full-color 20 degree, 38 PPD, 3,000-nit display as per his presentation and the AI SmartGlass platform was unveiled at the conference. Applied has a strong road map for higher performance products. The company is ready to accelerate a XR1 70-degree display with SiC (Silicon Carbide). As Ludovic Godet pointed out, the cost of SiC substrates must be further reduced to achieve target product cost requirements. Applied Materials also announced in September that it will develop waveguide components with GlobalFoundries (GF) as its high-volume manufacturing partner in Singapore.

Need for More, Faster and Better Pixels

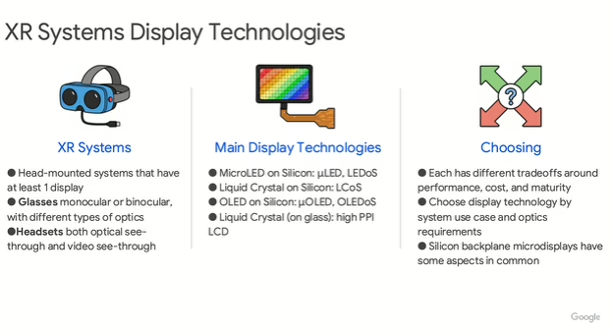

Carlin Vieri, Staff Engineer at Google, gave a detailed overview of XR display technology. He presented that there is a need for more pixels, faster pixels, better pixels as well as other requirements including lower costs, high reliability and lighter weight. He said key performance indicators (KPIs) for XR display technology are:

- Field of View (FoV),

- Pixels Per Degree (PPD)

- Latency

- Brightness to the eye

- Volume, weight, power

- Costs.

Depending on product requirements the display technology can be selected for AR smart glasses and VR headsets. Each display technology has different tradeoffs around performance, cost and maturity. Smart glasses generally use MicroLED and LCoS technology. MicroLED is an early-stage technology whereas LCoS is a mature display technology. MicroLEDs are inorganic LEDs arrayed on a silicon backplane.

Three main types of MicroLED:

- Single color per panel: optimized materials per color

- Single substrate-RGB; Blue LED + Quantum Dots

- Single substrate RGB without QD

As he summarized, “MicroLED is progressing quickly, LCoS is improving, MicroOLED resolution is great, and high-PPI LCD is reaching sweet spot”.

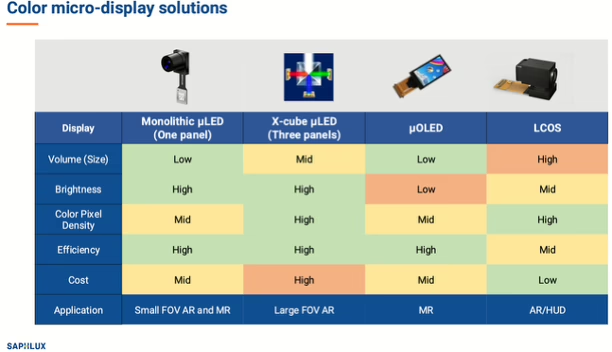

Need for One Panel Color MicroLED Displays

Chen Chen, CEO and co-founder of Saphlux focused his presentation on monolithic one panel MicroLED color displays for AR and MR. According to him, “Smart glasses could be the fastest-growing wearables in the next decade”. Saphlux has introduced a hybrid QD MicroLED full color display solution for AR glasses (0.13”, full color, 90% DCI-P3, 320×240 resolution, 0.7lm max luminous flux, 25-degree FoV, 0.2cc volume (targeting 0.15cc in 2026)). They have started shipping in small volumes of this one panel display product. Saphlux recognized that there are limitations in both quantum dot (QD) and MicroLED. The company developed a native blue emitter with QD green and red color conversion process (NPQD®), but as green QD sizes are smaller than red QD, they are more prone to defects and reliability is more difficult.

Saphlux has upgraded the process to native blue and green emitter with red color conversion layer (Hybrid-QD®) using Indium blue and green and QD red. This improves reliability and greatly helps with brightness and efficiency. He also reported that they have migrated to an all silicon-based system. Now it is feasible for them to shift towards a mass-producible lower-cost production. Saphlux’s 6-inch fab is already ready in China (5 million units/year capacity) and they are planning to shift to 12-inch fab in 2027, which can enable higher throughput and lower-cost displays. He said that when they shift to a 12-inch wafer, they can get larger size displays (1.4” display, 4Kx4K, 400K brightness, and high efficiency) for MR and other applications. In the next few years MicroLED display can also bring benefits to MR application. Chen Chen said, “We see that many companies have introduced single-panel MicroLED displays for AR glasses. Our goal is to bring monochrome, single-color AR glasses to full-color one-panel display, and give people a compact low-cost solution for that”.

Meta showed a prototype of its AR smart glass Orion in 2024. It was a concept product with MicroLED displays and Silicon Carbide waveguide (70-degree FoV). The recent Ray-Ban Meta Display glasses use LCoS display instead of MicroLED. Jason Hartlove said, “Even though there are some MicroLED-display-based AR glasses in the market, most are monochrome. For MicroLED displays to reach prime-time AR market, it will probably take another 8 to 9 years, as MicroLED displays today still have many challenges, especially in terms of image quality”. The industry has focused on efficiency and brightness in the past but now there is a need to focus on “more pixels and higher yields”. Fabs are not ready yet, and it will take time.

Need for Miniaturization of Display Panels

Mike Lee, technical Director, Display architecture at Meta focused on “miniaturization of display panels for AR”. He said, “AR glasses allow you to mix real and virtual. VR optics have been progressing towards more compact form factors. But we need to get the panel out of the way and into the frame for AR. What we need ultimately is the smallest set of display panels that we can fit in that frame”. He pointed out that “Pixels need to be in Silicon. Not only do transistors get squeezed as pixels get smaller, so does available metallization to bring power into the array”. Industry needs solutions. He explained that there is more to it than just array.

Traditional displays are static. In AR, display is attached to one’s head. When display is moving with the head, both real and virtual images can get distorted. In many devices, the array is only a third of the die area, with the rest devoted to pixel voltage/current management and processing logic. When Meta developed Orion prototype with MicroLED display they could lower voltage front-plane materials to enable silicon scaling with digital driving technology. They could leverage techniques from silicon industry to find ways to incorporate Through-Silicon-Via (TSV) processing in the display assembly process, enabling use of backside of silicon. These processes need to be industrialized for future development.

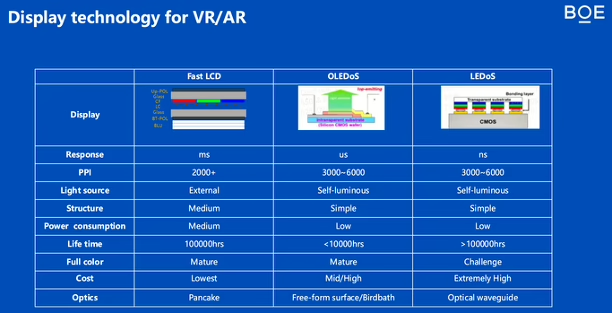

Need For Better Visual Experience

Hao Zhang, AR/VR CTO of BOE, focused on AR/VR high-resolution solutions. He said that higher Pixels Per Degree (PPD) in displays lead to better clarity and that higher FoV leads to a more immersive experience. He said the main challenges for AR/VR displays are high resolution (for clarity and fine details), accurate color (true-to-life colors), and excellent brightness (for clear visibility in bright environments). For displays: LCD has PPI limitation, OLEDoS (MicroOLED) has cost issues, and LEDoS (MicroLED) has full color limitations. There are also optical challenges such as color separation, ghosting interference and uneven brightness. There are system challenges such as extreme pressure on bandwidth and real time rendering.

Tomas Sluka, CEO and Co-founder of CREAL said in the conference that AR glasses today have inadequate visual experiences. There is a need to bring missing key performance indicators (KPIs) (Focus cues, Classic prescription lens), improve critical KPIs (See-through clarity, brightness per watt, affordability) and preserve other KPIs (FoV, resolution, form factor, color, compute.). CREAL focuses on light field display technology that incorporates vision care requirements and traditional eyewear features for AR. According to the company, “by projecting real 3D depth, CREAL’s unique light field display allows digital content to blend seamlessly into the real world, delivering a natural and correct visual experience”. Tomas Sluka presented that the FLCoS micro display they are using has unique strengths for AR: no motion blur, no color splitting, the smallest pixel pitch with low-cost process, high brightness (laser illumination) and maturity (low-cost CMOS process).

Kehan Tian, CTO of GoerOptics, focused on progress in diffractive optical waveguide technology for high-performance, large-view FoV. As he said, a waveguide can have many challenges: performance (high brightness, high uniformity), human factor (rainbow, light leakage, lightweight) and cost (materials and processes). Each substrate material (Silicon Carbide (SiC), Lithium Niobate (LiNbO3), glass or polymer) have their own capabilities and challenges. Silicon carbide substrate can provide a 70-degree FoV but multiple layers add complexity and trade off on weight, cost and rainbow. The industry has opportunities to improve material, process, equipment and optical performance.

Future Growth Needs Technology Development

- AR has finally arrived but higher adoption requires breakthrough in optics, displays and manufacturing at scale.

- MicroLED has the potential to be the leading display for AR, but it is not ready yet in terms of performance, yield, scalability and cost.

- AR success will depend on solving these challenges to become a truly immersive communication device.

Sweta Dash is the founding president of Dash-Insights, a market research and consulting company specializing in the display industry. For more information, contact [email protected] or visit www.dash-insights.com.