Since Apple bought Lux Vue, the interest in micro LED display technology has increased sharply. Recently several rumors around Apple’s involvement with the micro LED technology have been giving a good reason to reflect about the status of microLED displays.

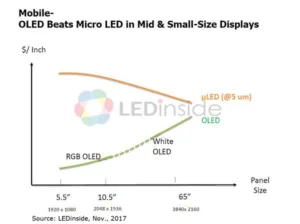

In an article by LED Inside (Where Micro LED Can Possibly Go After Apple Downsizes R&D Team), a rumor about the downsizing of Apple’s R&D activities within Lux Vue seem to indicate that Apple is reevaluating its strategic options in the display field. The article goes into more detail about the issues with the technology and comes to the conclusion that microLED technology is not cost competitive in small to midsize displays for mobile applications. In their cost chart they show that the cost of a micro LED display actually goes down with increasing display size and is closing the gap for large display sizes. This aligns beautifully with Sony’s and Samsung’s apparent intent to get into larger sized microLED based TVs.

LED inside – Micro LED versus OLED cost as a function of the display size

This rumor seems to go back to a Digitimes article (Apple reportedly whittles down micro LED R&D team in Taiwan) that also mentions the downsizing of Apple R&D activity in Taiwan. Nevertheless they come to different conclusions. They mention that Apple may be shifting their micro LED R&D activities back to the USA (there is no indication if this is just their opinion or based on inside information) as the short term application in mobile consumer devices seems be unrealistic. Of course, this could also indicate that there are difficulties with the microLED technology that are not easy to overcome.

In the same article, the writer also mentions cooperation between Apple and Taiwan Semiconductor Manufacturing Corporation (TSMC) to use Si wafers as backplanes for microLED displays. They note that this would solve the issue with placing the LED chips, which seems to be one of the issues with microLED technology. This might not appear to make a lot of sense at the first look, as the LED chips are based on other semiconductor substrates. On the other hand it would make it easier to manufacture the necessary drive electronic and possibly creating the interconnect.

All in all, this is another stumbling block for the microLED technology and indicates that creating a new display technology to take on LCD and now OLED is a pretty daunting endeavor even for Apple.

Analyst Comment

The development of micro LED technology was always about replacing typical display manufacturing based on semiconductor and clean room processing with a pick and place process based on the idea that the development of better LED chips would be driven by general lighting providing the high volumes needed to establish semiconductor manufacturing.

It now appears that both the micro LED and OLED approaches have their difficulties. In addition the market development for small to medium display panels is driven by an ever increasing pixel density requirement for smartphones. I believe that the difficulties in making a zero fault (remember pixel defects in TFTs?) display increases dramatically with the pixel density caused by placing ever smaller LED chips and connect them with an ever finer backplane. Since smartphone displays have almost the same display resolution as TVs today, it has to be much more difficult to place and connect this chips on a small backplane with much smaller leads. This compares to the same amount of chips placed over a much larger TV display panel. Both will certainly have their hurdles, however, at a first glance it seems that the processes for making small and large micro LED panels maybe indeed quite different and even more problematic in the case of small high resolution panels.

The latest rumors of Apple scaling back the micro LED R&D efforts in Taiwan may also hint at a quite different hurdle that they were not able to overcome. What if the manufacturing issues are caused by the interconnect and backplane in general? Such issues would make the cooperation with TSMC much more palatable as s solution pursued by Apple. (NH)