AGC, the Japanese glass company is offering an infrared transparent glass that would work well for automotive LiDAR and infrared touch panel applications. (Cars, Yes; Display Technology, Not So Much)

As was demonstrated by AGC during CES, the new glass enables LiDAR sensors to be put behind the glass without interfering with the functionality of the infrared laser, so the laser assembly could be put inside the car if the windshield was made entirely of the new glass. Alternatively the sensor could be put behind a cover glass made from this glass type. The car companies would prefer to avoid the ‘lump on the roof’ design constraints if a behind glass solution is not used.

AGC Infrared Transparent Glass – Credits: AGC / Wideye

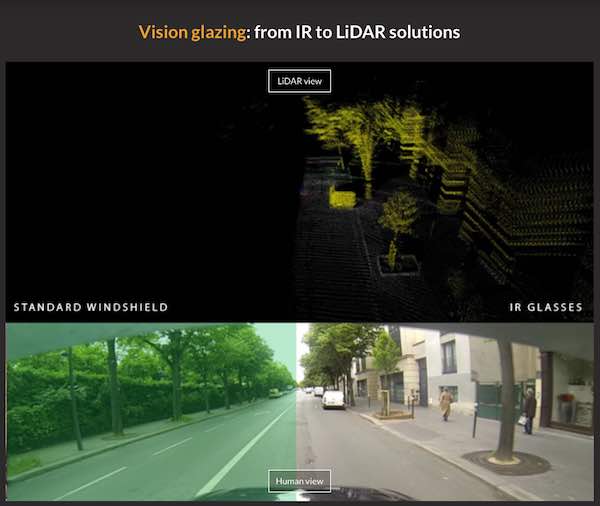

AGC Infrared Transparent Glass – Credits: AGC / Wideye

The picture demonstrates how the IR laser is absorbed in the standard windshield on the left (even though the green tint is a nice touch no windshield is that green these days) and the Wideye solution on the right. In the upper part of the image is the resulting 3D form the LiDAR system. It is clear that the AGC glass offers a big advantage for this technology.

Wideye is a subsidiary of AGC (the legal form is not quite clear) that is focused on supporting the automotive industry in designing and manufacturing prototypes.

Another technology that needs such glass is the infrared touch technology as the one developed by FlatFrog. With the reduced IR absorption the panels can be larger and the resolution of the touch panel is better based on reduced losses.

Analyst Comment

IR transparent glasses are not new, but have been used so far for optical applications such as laser windows and optical components. They were expensive and often difficult to work with. Existing borosilicate glasses use very low iron raw materials (i.e. sand) which makes the glass more expensive than soda lime glass and limits its range of applications.

AGC’s new glass is based on the float process and uses an Al-Borosilicate glass type that is cheap compared to most optical glasses, but still more expensive than the standard soda lime glass that is used today in car windshields.

The issue with silicate glass types and IR transmissivity is the presence of iron (Fe) in the raw materials. Small amounts make the glass green or absorb in the IR region, depending on the redox state of the iron in the glass. While Fe (III) absorbs in the short wavelength region of the visible spectrum and the near UV, Fe (II) absorbs in the IR region. AGC uses trace amounts of Cr-compounds to push the Fe contamination into the Fe (II) state. This has to be done carefully as Cr itself is also coloring the glass as an undesired side effect. This way AGC can use cheaper raw materials and further reduce the cost. The glass seems to be described in the patent application US2016015968120160159681. (NH)