It’s no secret that OLED and QLED have battled head-to-head for the past few years for the top spot in display technology. Last week I was one of the few quantum dot representatives at the OLED World Summit 2019 held in San Jose. While I felt a little bit like a fish out of water, it was a welcoming crowd and I learned a lot (and hopefully was able to educate the OLED community as well). Here are 4 of my takeaways from the show:

-

Flexible/Printable OLED is gaining momentum

We all know about the various flexible mobile phones that have been introduced and re-introduced in the past year. You can debate all day long whether the impending flexible wave is necessary or not, but the fact remains that there are plenty of electronics companies working on these devices, and plenty of scientists developing new materials to make these devices better/cheaper.

In a future world it would be ideal to print displays like newspapers, on a roll-to-roll (R2R) process on either flexible ultra-thin glass or on plastic. But in order to do this some of the materials are going to have to change. It’s still expensive and wasteful to evaporate OLED materials onto substrates – flexible or not. There were some excellent talks on progress using printable OLED inks. Kateeva is looking at printing OLED devices and quantum dot materials in hopes of leveraging their ink-jet printing platform for next-gen displays. Industrial Technology Research Institute (Taiwan) shared a custom facility with a combination of evaporative steps and printed layers to achieve OLED lighting panels on a R2R process. Professor Choi from KAIST shared some incredible developments in OLEDs and solar cells on fabrics that can withstand washing machine cycles and remain functional (a necessary feature if wearable OLED is really going to take off). An impressive result he also shared was their progress on OLED fibers that can be woven into clothing.

OLED fibers in fabric (image from Nano Lett. 2018, 18(1), 347-356)

While not present, there were many mentions of the company Joled which has made fully functional displays (computer monitor-sized) in the past using printed OLED materials. Fully printed OLED displays of this type would cause a paradigm shift in the OLED supply chain and manufacturing. (they continue to be released EIZO Releases Its First Limited Edition 21.6-inch OLED Monitor for Private Entertainment of 4K and HDR Content – Editor)

-

Blue is a bottleneck

For materials to emit blue light, energy needs to be pumped into the material at higher levels than for red and green (blue wavelengths are higher energy than other visible colors). This means that not only does the emissive material need to change, but the adjacent materials as well. It’s not trivial to make a blue emitting OLED of the proper color, and even less trivial to make it efficient and long lasting. Both Cynora and Kyulux shared their strategies and struggles with producing the right blue with appropriate stability for commercial applications. In the end, something has to give – color, efficiency, or lifetime. The trifecta is still a challenge to realize.

-

OLED Lighting is still looking for the “killer app”

It was amazing to see all of the design concepts for OLED lights in offices, airplanes, cars, even on clothes. OLEDWorks and Acuity shared the spotlight for one presentation showing some unique designs and spaces where OLED lighting could really make an impact. The differentiation here was the design, light uniformity, and aesthetics of the fixture. It is tough to make a case for OLED lighting specs to beat LEDs in many categories, so the highlights tend to be the novel designs enabled by OLED. In one implementation they combine LED up lighting with OLED down lighting, presumably to capitalize on the design freedom of OLEDs and mature technology and efficiency of LEDs. While these lighting products look impressive, they remain niche products, in part due to the continued decline in the cost of LEDs.

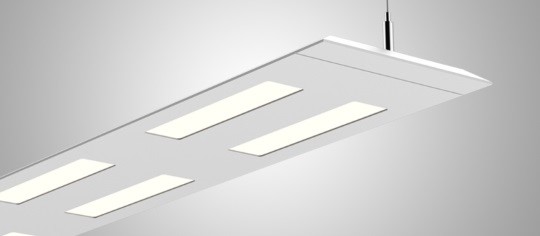

A combination product from OLEDWorks/Acuity containing LEDs (up lighting) and OLEDs (down lighting) in one unit.

A combination product from OLEDWorks/Acuity containing LEDs (up lighting) and OLEDs (down lighting) in one unit.

Another niche implementation is the use of red OLED in car taillights. Audi spoke about the success they have seen in this implementation in two of their models, which they hope to expand in the near future. Again, here the major benefit is the new design/look that can be achieved with OLEDs that are difficult to do with LEDs. While current designs are fairly simple and contain an array of <10 OLED pixels, future design options are really exciting, including a larger array of dozens of small triangular shaped OLEDs so that the tail lights can be a “display” of sorts. In this strategy, tail lights could share information like a caution triangle, or various patterns to alert other drivers the vehicle is in autonomous mode. Audi claims the demand was way higher than anticipated for these taillights, so they had to up their capacity and find new OLED suppliers to meet the demand.

Boeing presented a unique future in which a plane had no windows, only OLED illuminated sky above the passengers, complete with clouds and sun, or a starscape at night. There are various other implementations of OLED lighting and displays in planes, but I thought the windowless airplane was the most unique. And apparently there are real implications in fuel economy and weight if customers will tolerate the lack of natural light and are willing to forego the view of our planet from 30,000 ft. Not sure I’m ready to fly in a black box yet.

All of the very unique (but low volume) applications tells me that OLED lighting is starting to find it’s niche, but has yet to discover the “killer app” for this technology. OLED displays found this in mobile a few years back, and now is commonplace in our pockets. But I’m guessing very few of us see an OLED lighting module on a regular basis (unless you drive an expensive Audi).

-

QLED and OLED continue to collide

The OLED Summit invited two (potentially) competing technologies to the conference – QDs and microLED. From the microLED side, Plessey shared their progress on monolithic microLED displays. They rely on QDs to achieve full color using blue microLEDs.

In a workshop that preceded the conference, I spoke about the trends in electroluminescent QLED (EL-QLED) as well as unique photomedical applications of QLEDs and OLEDs. The team at Fraunhofer IAP shared some of their progress and challenges in realizing Cd-free EL-QLED.

Nanosys presented their work with LG on EL-QLED. They continue to improve performance and should catch the attention of those working on OLED printed displays. High efficiencies (>>10%), excellent color purity (now commonplace for QD technology), and consistently improving stability were some of the highlights. A special highlight for me was the progress in blue EL-QLED devices. Only a year ago there was virtually no Cd-free blue EL-QLED data available, and now lifetimes >100 hours are being reported with Cd-free blue QLEDs at 450 nm and peak widths <30 nm.

Although it was not a focus of any presentations, QD-OLED was mentioned by many speakers and in many networking discussions. Rumors about this approach have been floating around for years but the challenges in full blue conversion, blue OLED lifetime, and light management have resulted in delays to commercialization. I wrote on this topic in a past DD article found here.

Summary

OLED technology continues to impress customers with its excellent black levels, thin form factor, and flexibility. There are a lot of innovations still to come out of this community but leveraging the advantages of QDs could be key to realizing displays of the future. Thanks for welcoming this fish to your pond OLED community, I look forward to next year’s event! PP

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.