Do you remember the world largest Plasma TV? The 152” monster released in 2010 was made to show the supremacy of PDP over LCD in the large screen TV market segment. As it turned out this did not delay the end of the PDP TV run as LCD got better and cheaper and finally took over the market.

While something similar is going on right now between LCD and OLED, I am turning my attention to the 146” Samsung microLED TV called the Wall. Similar to the 152” it is for sale and if your personal finances allow to upgrade your TV room without a second mortgage you may already own the 152” Panasonic PDP TV. In that case would the loss of 6” in the diagonal feel like a downgrade to you?

Besides the actual price, which Samsung has not released yet, PDP developed the ultimate large size TV as it was under pressure from LCD in smaller sizes, the Samsung Wall was a demonstration of a modular panel format based on microLED technology. While PDP was going big to show its superior technology, Samsung went big because of the limitation of the microLED technology. A fine but distinct difference.

Since the raised question involves me, I want to make this question a bit clearer. While I am planning to buy TVs for another two decades, assuming good health and wealth of course, the question boils down to the market chances of microLED in the TV market over the next two decades. If we consider the Samsung Wall announced in 2018 as the starting point of microLED TVs, we need to assess the chances of being cost competitive with LCD / OLED going forward. This requires a look at the technology.

Right now microLED is taking a little bit of the ‘Next Big Thing’ status away from AR/VR, which typically means it is great to write about it without being proven wrong within the next few years. In addition there is plenty of technology development going on in this field to allow speculation on a daily basis. There are plenty of small companies working in this field, suggesting new approaches to solve the cost restraints microLED has today. Let’s take a look.

Transfer or Pick-and-Place.

There are two major approaches in microLED. One relies on placing distinct LEDs with red, green and blue emission on predetermined positions of a backplane and connect them all to the display driver in a similar way as we do today with an LCD or OLED. This is shown in the report from Yole Développement as presented below. In the case of the microLED, we could drive the current similar to an OLED if the LEDs are showing all the same luminous output per amp. If this is difficult to achieve, we need to pulse the device to achieve brightness control. In general I would expect brightness uniformity to be a bigger issue for microLED compared to LCD or OLED.

YOLE Développement – microLED Report 2017

Pick and place has a yield as any other manufacturing step has. Putting down 3 x pixel resolution distinct LEDs and connecting them without any failure is not so easy. Remember the time when LCD screens came with faulty pixels? This is not really acceptable today and this is one of the issues microLED has to solve.

The other solution is a transfer approach of UV or blue emitting LEDs from a carrier substrates to the backplane. While the connection issues are similar to the pick and place scenario, the display area represents the same area on the carrier substrate. This means that the cost of making LEDs has to be low enough to compete with LCD cost. Since the backplane and drive scenario are very similar we can compare LCD / OLED material cost and the cost for the front plate with the cost of making LEDs in an epitaxy process and transfer them. It’s not so clear which will have the lowest cost in the long run.

Large or Small Displays – pick your poison.

Some insist that small displays are the optimal target for this upcoming technology while others believe that the large screen applications are easier to penetrate. Besides the technical issues as discussed above, we also have to consider the application requirements. For both market segments, small and large displays, microLED has something to offer but also has to overcome the position of other technologies. LCD and OLED display screens are very good by any means and with the addition of quantum dots the boundaries are getting even smaller.

While small displays have a form factor that would make either approach of transfer easier, they require a higher pixel pitch and by that notion, smaller LEDs as well. The smaller the LED device the more difficult the interconnect. The drive towards even higher resolutions in smartphone, for example, makes it difficult for microLED to be competitive from the get go.

The most straightforward idea is the use in wearable devices. The power consumption and outdoor view ability of microLED displays are expected to be very good and as a consequence they should be able to compete on performance and on price alone.

Others have suggested that developers should go after a large display application like TV and signage, where the high brightness and long lifetime together with great contrast should make them competitive, at least based on performance. But then there is the cost factor that plays an important factor in commercial and TV markets as well.

On the negative side, the wider the application choices for developing companies the greater the possibility of splitting the total development effort into smaller application specific efforts. Better to be first in an application segment than second in one that contains all developing companies, right? While that may be true for the individual development companies, it could be detrimental for the overall development of the technology. Competition is a strong motivator.

What makes me nervous.

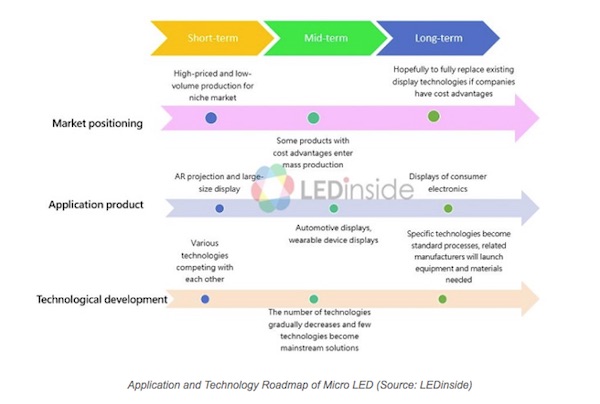

One of the issues with microLED is the absence of any industry understanding of where this technology is going. We are at a point where everyone is working behind closed doors without any glimpse on how far away from a commercially viable product they really are. For example the only microLED roadmap that is published on the internet comes from LED Inside. Not one manufacturer has published anything of substance. Even this one is less than forthcoming with any detail that would hint at a release date.

The chances of one company solving all the involved issues is not very large and until there is wider industry cooperation I am hard pressed to expect a microLED TV in my price range anytime soon. For example, home grown equipment and tools to make a display are typically the sign of a prototype stage and commercial success being still many years away.

Credit: LED Inside

Credit: LED Inside

The other issue is the absence of patent applications in this particular field. If we expect this technology to take over large display applications, you can be sure that IP protection will play a very important role in the success of specific companies. Technology needs to be protected and while the current patent situation is not very supportive for the developing companies per se (who wants to sue Samsung or Apple?), it is the only chance to protect your IP once products enter the market. I did show the patent trend in my last article ‘Apple and microLED – The Saga Continues‘ and it is not supportive of the idea that microLED will be the main display technology within the next few years.

Taking all this into account, I am hard pressed to say that the chances that I will ever buy a microLED TV are high. At least I can still hope or win the lottery and get the Samsung Wall anyway. NH