This was a record breaking year for the iZone at the annual Society for Information Display Display Week. Launched just seven years ago, the innovation Zone or iZone has grown to almost 50 booths and split into two different sections on the Display week show floor with lots to explore in cutting-edge technology. For example the prototype winner this year is a new very fast field sequential color display that could replace IPS or FFS modulation for portable mobile market.

Probably the most sought after technology of DisplayWeek, microLED was represented, but also light-field displays, transparent, low cost printed color displays and chip on display technologies. There was even nano-based electrode printing for high value device repair.

Here are some highlights from the innovation zone space on the show floor.

Hong Kong University of Science and Technology

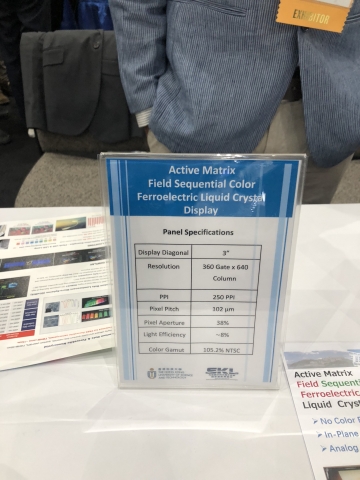

This group had a 3″ diagonal, 250 ppi active matrix field sequential color display panel based on electrically suppressed helix FLC (ferroelectric liquid crystal or ESHFLC)

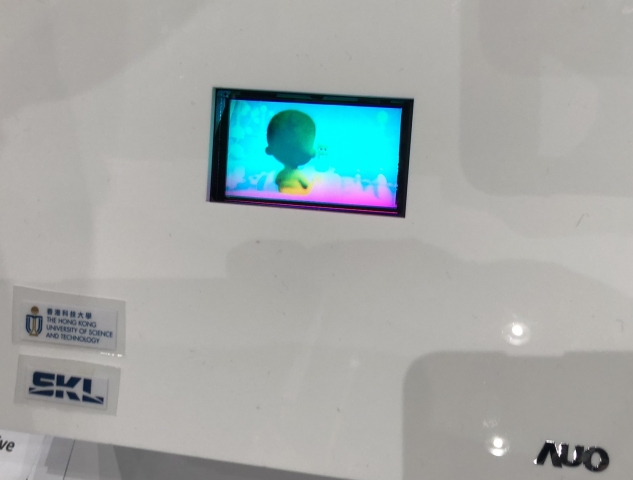

3-inch diagonal, 250 ppi active matrix field sequential color display, Source: Sechrist

3-inch diagonal, 250 ppi active matrix field sequential color display, Source: Sechrist

The group demonstrated a 3″ color display operating with an ultra fast response time (~10μs ) at very low voltage (6.67V/μm) that enables a 60 Hz frame rate with a 360-Hz FLC drive frequency. The photo-alignment technology provides ESHFLC with optimal “anchoring energy” which contributes to a high contrast ratio over 10K:1.

The delivered prototype shown includes a 3T1C pixel circuit that’s designed to convert the analog drive signal to run in a pulse width modulation mode. The field sequential color ESHFLC display is achieved on LTPS TFT panel resulting in an active matrix FSC ESHFLC integrated display system Benefits include

- No color filters

- In Plane switching (IPS) with color shift better than traditional IPS LCD

- Analog graysale

- High light efficiency panel (8%)

- 3X resolution (360 gate x 640 column) without any sub pixels

- Wide color gamut at 105.2% NTSC.

Team sent to iZone 2018 from Hong Kong University of Science and Technology, Source: SechristThe display offers the possibility to replace IPS or FFS modulation in the portable mobile market. The high resolution FSC ESHFLC can also find more applications in emerging virtual reality displays. The group won Best Prototype in the iZone, along with a distinguished student paper in the 58-4 session given at Display Week, titled: Active Matrix Field Sequential Color Electrically Suppressed Helix Ferroelectric Liquid Crystal for High Resolution Displays.

Team sent to iZone 2018 from Hong Kong University of Science and Technology, Source: SechristThe display offers the possibility to replace IPS or FFS modulation in the portable mobile market. The high resolution FSC ESHFLC can also find more applications in emerging virtual reality displays. The group won Best Prototype in the iZone, along with a distinguished student paper in the 58-4 session given at Display Week, titled: Active Matrix Field Sequential Color Electrically Suppressed Helix Ferroelectric Liquid Crystal for High Resolution Displays.

To demonstrate that the FSCD quality depends on LC switching speed,the group compared four different LCD modes used for field sequential color displays, including IPS, TN, VAN-ECB, and FLC on the single pixel level. Comparisons included the color shift, color triangle, viewing angle and other attributes.

For more details, contact: Hong Kong University of Science and technology Abhishek Srivastava [email protected] ;

Dimenco

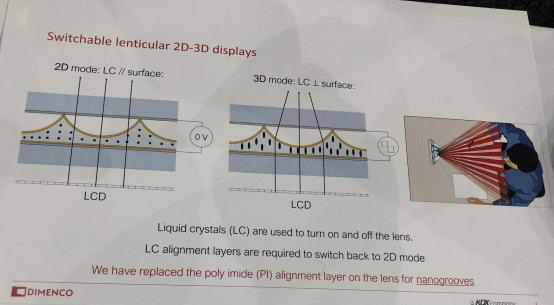

Dimenco showed their newest LC alignment layer for switchable lenses. Their glasses-free 2D-3D switchable displays are made by applying lenticular lenses on top of a display (Philips method shown in 2010 – earlier? – actually Steve, since 1996!). The lenses are turned on and off by switching the orientation of liquid crystals.

What’s new is that they replaced the conventional polyimide alignment layer on the lenticular lens with nanogrooves, that improves the alignment of the liquid crystals. In doing so, they could eliminate the polyimide layer which simplifies the production process and improves the optical quality of the lens, while reducing cross-talk “significantly,” according to Maartin Tobias, of Dimenco.

Glasses free 3D 2D switchable display using lenticular lens on top of a liquid crystal display using an alignment layer for the switchable lenses., Source Sechrist

Glasses free 3D 2D switchable display using lenticular lens on top of a liquid crystal display using an alignment layer for the switchable lenses., Source Sechrist

This company has been around since 2010 and founded by Philips 3D display engineers. Perhaps the real question is to what significance is a glasses free 3D display in the age of VR, AR and 8K devices? Some would say very little on the commercial side, but 3D continues as a niche display with many commercial and medical applications.

Contact: Huub Kuringen, [email protected] ;

Newest Dimenco 3D panel shown at SID Display Week 2018 iZone, Source: SechristBJD

Newest Dimenco 3D panel shown at SID Display Week 2018 iZone, Source: SechristBJD

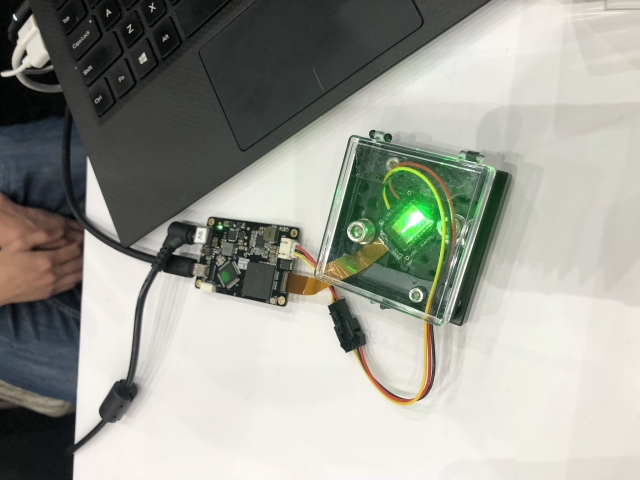

Hong Kong Beida Jay Bird Display (BJD) showed an active matrix microLED in a chip format with 5K pixels per inch and 1 million cd/m² of brightness.

JBD high bright green micro LED on IC, shown at iZone, Source: Sechrist

JBD high bright green micro LED on IC, shown at iZone, Source: Sechrist

The micro LED on IC panel specs include 640 resolution, 20µm pixel pitch, R/G/B single color, 256 gray levels, more than 500K cd/m² (green) brightness, at an operating voltage of 5.3V with typical power consumption of 6W at 60Hz refresh.

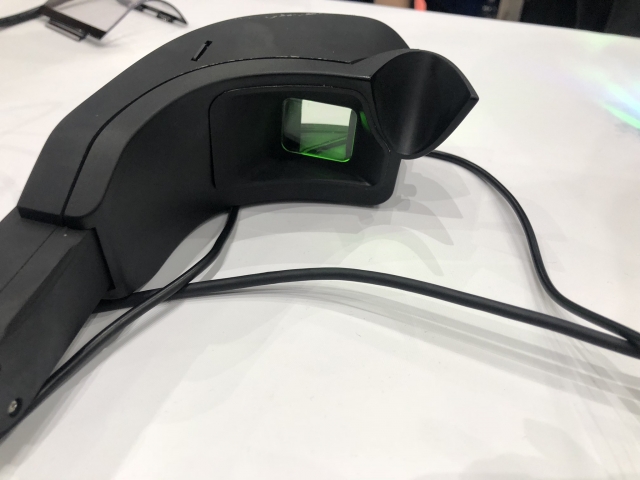

JBD micro LED integrated into NTE device, shown at iZone, Source: Sechrist

JBD micro LED integrated into NTE device, shown at iZone, Source: Sechrist

This microLED was based on monochromatic red, green, and blue micro-display panels. They also showed application demos using their panels. The microLED microdisplays were made using a “monolithic hybrid integration technology” with exceptional brightness and resolution characteristics.

Application areas include a portable projector with ultra-high brightness microLED microdisplays in excess of 3 million cd/m² (for the green color), and AR goggles (augmented reality) using an ultra-high resolution microLED microdisplay (with a pixel density of higher than 5K ppi.)

Contact: Hong Kong Beida Jade Bird Display Ltd., Fang Ou, [email protected] ;

PlayNitride

PlayNitride Inc. created a transparent display using a unique process to transfer its RGB microLEDs on to the backplane substrate.

The group showed a 3.12″ diagonal 256 x 256 resolution transparent full color RGB microLED display with a brightness of more than 800 cd/m² and color gamut of 113% of NTSC. The pixel size is 0.219mm and the group claimed it represented the equivalent of section of a 76″ diagonal 8K display. The mass transfer process is characterized as 8 shot per color and 24 shots per panel with microLED quantity at 262K chips / color and 786K chips per panel.

Three demo displays were shown,

- a 0.8″ 230 ppi display with 128 x GGG x 128 pixel resolution and transparency at 20 to 30%;

- the second, a 103 ppi display, had a 0.89″ diagonal 64 x RGB x 64 pixel resolution, with more than 600 cd/m² brightness, 100% NTSC color gamut and 50% transparency.

- The final and largest display demo was of a 68 ppi 2.65″ 128 x RGB x 128 resolution panel at >800 cd/m² brightness, with 113% NTSC, and 48% transparency.

Contact: PlayNitride Inc. Falcon Liu [email protected] ;

3.12-inch diagonal transparent micro LED display, Source: Sechrist

3.12-inch diagonal transparent micro LED display, Source: Sechrist

XTPL sa

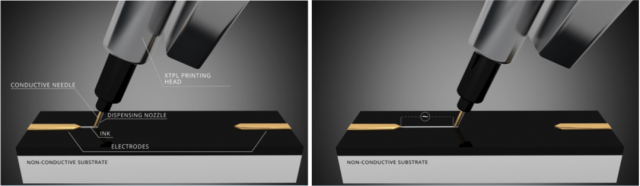

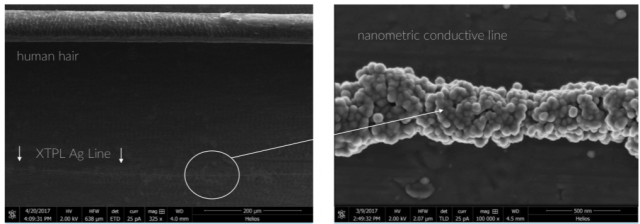

This company has developed technology that enables ultra-precise printing of nanomaterials. The XTPL solution allows users to repair the interrupted thin conductive lines in the production stage, without complicated, slow and expensive vacuum processes, the company says.

To get there, XTPL created an innovative process for printing electrodes that are several hundred times thinner than a human hair, with conductive lines (less than 100nm) Initial use is for corrective procedures in high-cost manufacturing.

XTPL created a unique printing-head and dedicated nanoinks for repairing defects in electrical connections at micrometric & nanometric scale (conductive lines from 100 nm to 3 µm). There is also an optical detection systems that is already used on the market to provide a full technological solution the company can implement on production lines.

Target markets include solar cells, LCD/OLED displays, PCBs, MCM multichip modules & integrated circuits.

Contact: XTPL S.A., Marta Ziobrowska [email protected];<br

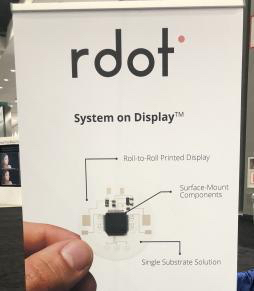

rdot AB

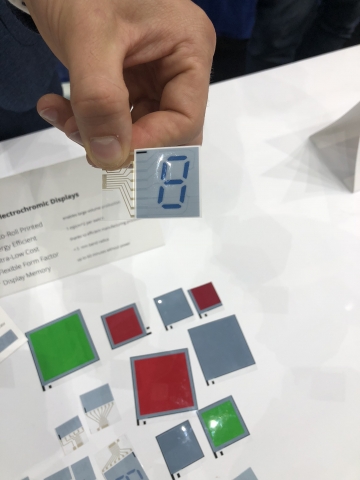

rdot AB has a low cost printed electrochromic color display

Displays National Institute of Technology, Sendai College, Sendai 981-1239, Japan

The group is working on developing and commercializing an ultra-low-cost and energy efficient reflective electrochromic color display. Manufacturing goals for the printable electrochromic display include small and large format and multiple shapes, and forms. The group said they have close-to-market prototypes including segment displays, and we demonstrate an RGB pixel currently in development. On their roadmap, this full color reflective display is their next generation target.

What was shown: A chip component that is surface mounted on an roll-to-roll display This represents a single substrate solution

Benefits: Roll to roll enables large-volume production, with benefits that include energy efficiency (1mj/cm² or millijoule 1/10,000 of a joule per sq. cm) per switch, ultra low cost due to mature manufacturing processes, flexible substrate with a less than 5mm bend radius and offers a static display memory that lasts up to 60 minutes without power.  Applications include iOT (internet of things) display, medical devices, wearable technology, smart cards, ESL (electronic shelf labels), digital signage, including smart packaging, smart home devices and even a reflective indicator light.

Applications include iOT (internet of things) display, medical devices, wearable technology, smart cards, ESL (electronic shelf labels), digital signage, including smart packaging, smart home devices and even a reflective indicator light.

For more details contact: Kalantar Kalil, [email protected]

Fovi3D Light-field display

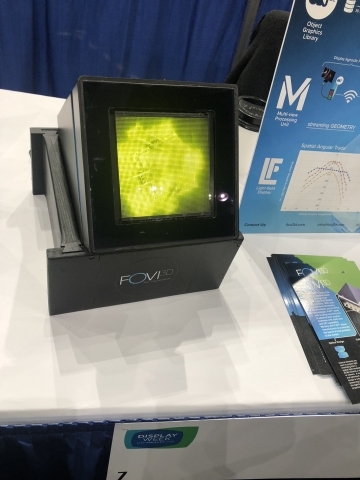

FoVI3D showed its glasses free 90 x 90mm full parallax, horizonal light-field display (DK2) with a 90º projection frustum. The technology projects a 3D aerial image with all the expected depth cues required to create a “natural visualization experience.”

Light-field display from Fovi3D includes entire ecosystem, Chips, API’s, Dev kits and calibration to create total solution, Source: Sechrist

Light-field display from Fovi3D includes entire ecosystem, Chips, API’s, Dev kits and calibration to create total solution, Source: Sechrist

Optical elements are used to project light from a spatial light modulator (SLM) toward the viewer. Fovi said it is critical for the optical design to be correct and optimized so they focused on both calibration and developing their own set of agnostic API’s (application program interfaces) an independent processor that minimizes support and interconnect needs and is scalable to specific display architectures. Fovi calls this a new display rendering paradigm.

For example they have a patented process to calibrate light-field displays that analyzes thousands of images from multiple perspectives and uses advanced algorithms (ok, math) to optimize the light-field projection.- Exciting.

Light-field technical specs include:

- Enclosure dimensions: W:15.5cm x H: 22.0cm x D: 15.5cm

- Display interface, Raw hotel stream API, ObjGL with FoVI3D render

- 9cm x 9cm x 9cm active light field volume

- 60-degree field of view (fov)

- 0.5mm hogel diameter

- 180 x 180 hogel display

- 50 x 50 views per hogel

- Five USB 3.1 gen2

- Power: 120/240 Vac, 75W

The developers kit 2.0 supports multi-user visualization by projecting thousands of perspective correct rays of light.

The company is also working on a graphic language and hardware to support for multi-view rendering.

Fovi3D said they are working to help develop the entire pipeline, from data distribution to the visual experience.

Contact: Amy Lessner [email protected]

Information College of Nankai University, Tianjin, China

Personal Stereoscopic Cinema Comes to the iZone

This group showed a patented technology using “non paraxial axis optics” that delivers a 3D experience without the passive polarizing glasses, or active LC shuttering more commonly used. Called a personal stereoscopic cinema device, the technology was shown earlier this year at the ICDT International conference in Guangzhou, and made it to the iZone exposition this year. it came from a development initiative under Dr. Ding Shou-qian, and China’s 4G/5G communication initiative with the promise of high-definition, full color, and high brightness with quasi naked eye stereoscopic display.

Dr Ding said his purely optical system can reach 4K level output and the system shown at the exhibition used a dual screen with a resolution of 2560 x 1440. —Impressive.

Contact: Dr Hui-Zong-one Jai CEO, Voidsee Technology Co., Ltd. [email protected]

Summary

This year’s iZone did not disappoint with an extended number of new and emerging technologies on display. We saw some game changing and horizon prototypes, devices and applications in displays, and even harbingers of the past including new updates on 3D passive displays and even an optical 3D solution.

Past, present and future were all here with some exciting prospects for the future, and yes, it was shown first in a humble 10 x 10 innovation display booth as part of SID’s Display Week. So hats off to the hard working iZone committee and most of all, E-ink with their visionary charter membership and ongoing generous sponsorship of some of the most interesting technology at Display Week. – Steven Sechrist