In the session on head-up displays, Olli Pekonen (Beneq Oy, Espoo, Finland) presented thin-film electroluminescent displays (TFELs) as being well-suited for vehicular applications. The operating temperature is -100ºC to +100C, there is virutally no latency, custom shapes are possible, and Beneq produces the Lumineq IGLT line of TFELs that are ready to be laminated into exterior or interior automotive glass.

A Beneq Lumineq thin-film electroluminescent (TFEL) display laminated into an SUV’s side window. (Photo: Beneq/Lumiteq)

Because TFELs are transparent, they are suitable for the top layer in a “3D” (really multi-layer) instrumentation display.

A Beneq Lumineq TFEL as the top display layer in this “3D” instrument module. (Photo: Ken Werner)

A Beneq Lumineq TFEL as the top display layer in this “3D” instrument module. (Photo: Ken Werner)

Evolving Display Technologies and Supply Chain.

Brian Rhodes (Automotive Technology Analyst, IHS Markit) was the second speaker, with “Evolving Display Technologies and Supply Chain.” He presented data indicating that for the center stack, sales of 7.x- to 8.x-inch displays are about double that of 5.x- to 6.x-inch, with sales of 7-to-8-inch increasing rapidly between now and 2023 and sales of 5-to-6-inch declining slightly. Sales of all other sizes are far behind, but Rhodes projects sales of 9-to-10-inch to grow significantly, and expects them to be a strong third beginning in 2018. By itself, Tesla will not be able raise 11-inch-and-above displays beyond fifth place through 2019, but the continuing decline of 4-inch-and- below displays will elevate them to fourth place by 2021. The three largest of makers of center-stack displays, said Rhodes, are Panasonic, Visteon, and Continental.

Brian Rhodes (Automotive Technology Analyst, IHS Markit) was the second speaker, with “Evolving Display Technologies and Supply Chain.” He presented data indicating that for the center stack, sales of 7.x- to 8.x-inch displays are about double that of 5.x- to 6.x-inch, with sales of 7-to-8-inch increasing rapidly between now and 2023 and sales of 5-to-6-inch declining slightly. Sales of all other sizes are far behind, but Rhodes projects sales of 9-to-10-inch to grow significantly, and expects them to be a strong third beginning in 2018. By itself, Tesla will not be able raise 11-inch-and-above displays beyond fifth place through 2019, but the continuing decline of 4-inch-and- below displays will elevate them to fourth place by 2021. The three largest of makers of center-stack displays, said Rhodes, are Panasonic, Visteon, and Continental.

In 2017, sales of windscreen HUDs substantially are about four times that of the combiner-type. Both types will grow rapidly (from the current, relatively small base) says IHS Markit, but the combiner type will grow more rapidly and nearly match the sales of the windscreen variety by 2023. The leading manufacturers in 2017 are Nippon Seiki, Continental, and Visteon.

Displays with curved front surfaces are appearing in vehicles such as the Audi A8, Range Rover Velar, and Subaru Impreza, but they are flat displays with curved cover glass.

AMOLED displays could grow to 2.5% of the automotive market by 2026 from essentially zero today. OEMs are very interested, but the supply base is limited, said Rhodes. And OEMs and Tier 1 suppliers are concerned about lifespan issues, automotive grading, and cost constraints.

Rhodes commented that digital side view mirrors could produce fuel efficiency (or battery life) gains of 3 to 6%. Regulations in the EU and Japan already accommodate digital mirrors, and he expects that the U.S. will join this club in 2018. Digital rear-view mirrors are already in use because, since they are switchable between their digital and conventional mirror modes, they get around many regulations.

Rhodes also observed that if touch is the primary HMI mode, the display must track with seat position.

Automotive Market’s New Opportunities for Touch Screen, Touchless Control, Flexible Display and Smart Windows

In her invited address, Jennifer Colegrove (Touch Display Research) noted that the many HMI technologies used in vehicles include touch, voice control, gesture control, face recognition, proximity sensing, photodiode, radar, lidar, ultrasound, and baby sensor. She reported that LGD has said it will have an AMOLED auto cluster in production in 2018, and forecast that automotive ADAS (advanced driver assist systems) and touchless HMI revenue will increase from about $16 billion this rear to $60 billion in 2023. This compares to automotive display revenue of about $7 billion this year growing to about $13 billion in 2023, Colegrove said.

Next Generation Augmented Reality Head-up Display with DLP Technbology.

Mike Firth delivered a presentation for the DLP (digital light processing) business at Texas Instruments. Firth was promoting the eventual use of lasers with DLP micromirror devices for vehicular use; “eventual” because lasers do not yet have the maximum operating temperature required for vehicles. Lasers are used in non-vehicular projections, though, and 70% of those systems used DLP technology, he said. Firth stated that using laser light sources rather than LEDs produces more collimated light cones, which result in less scatter and superior black levels.

Using a laser instead of LED light source with a DLP device produces more defined light cones, less scatter, and better contract ratio, says Texas Instruments. (Image: Texas Instruments/DLP)

John van Derlofske described a new 3M reflective polarizer with approximately 700 layers for vehicular applications. The film is laminated directly to the display’s rear polarizer. It is not free-floating, as is usually the case for films in a display’s optical stack. For HUDs, mirror systems, and LCDs, the new the reflective polarizer offers improved efficiency, reduced thermal loading, improved durability and ernvironmental stability, and reduced thickness, van Derlofske said.

Interpupillary Distance is Important

Joe Pullukat (Applications Engineering Dept., NSI) discussed the importance of interpupillary distance when aligning AR HUD graphics.

Because precise registration is required between tje virtual image and real objects of interest, misalignment can cause misinterpretation of information. Among these misinterpretions is difficulty in differentiating the AR data from the real world. So, to the many other AR HUD design requirements, we must add “driver head tracking systems to allow for re-alignment of the virtual image when the driver’s head moves, keeping the image on target.”

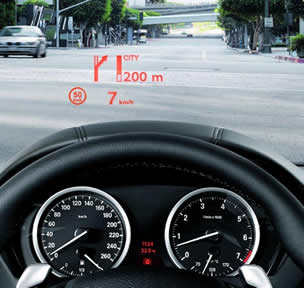

An NSI HUD used in a BMW 5 Series. Image:BMW

An NSI HUD used in a BMW 5 Series. Image:BMW

But (most) drivers have two eyes, and the alignment difference between the eyes can cause significant errors. Which eye should we align to? One might be tempted to align to the dominant eye. But two thirds of the population is right-eye-dominant and one third is left-eye-dominant, and there is “no practical way to input dominant eye position data into the AR HUD graphical output to align to the virtual image.” So AR systems will approximate the dominant eye position as the center of both eyes.

Pullukat concluded with a four-point summary:

1) The error caused by the dominant-eye mismatch must be quantified;

2) This error must be added to the overall error stack and compared against the HMI requirements;

3) This error may required more advanced AR HUD systems or compromised HMI strategies to prevent the driver from receiving misleading information;

4) 3D HUDs are an interesting way of addressing this error.

Why haven’t AR HUDs made it to producton?

The Daqri Automotive team offered a HUD tutorial that attempted to answer the question “Why haven’t AR HUDs made it to producton?” Among the reasons are significant integration challenges. Each vehicle platform has a unique windshield design that requires a specific HUD optical design. In addition, windshield surface variations can produce distorted images so windshields to be used with HUDs require more stringent manufacturing tolerances.

A large field of view (FOV) is required for a fully functional AR HUD, but the large the FOV, the more volume the HUD consumes behind the dashboard, which is a very crowded place. “The smallest HUD shown to date is 12 liters,” said Daqri’s Rich Sanders. But three promising solution to reducing HUD volume is polarized beam folding, a holographic optical element (HOE), and a laser holographic approach. The approaches are not mutually exclusive. HOEs seem to be Daqri’s chosen approach. They are working with TI to develop a practical system.

Daqri HUD Concept.

Daqri HUD Concept.