Recently I had the opportunity to have a chat with QNA Technology CEO, Artur Podhorodecki. QNA is a startup company in Poland focused on developing blue QD technology. As those in the display industry can attest to, blue has always been a challenging color to tame in emissive devices, for both OLED and QD-EL (Quantum Dot Electroluminescence, also known as EL-QLED, NanoLED, QLED, among others). Artur and I talked about QNA’s technological development and what is in store for the future. Here is a summary of our chat followed by my commentary on their impressive QD-EL results.

Tell me about your company, QNA Technology.

QNA was established in 2016 by me and my academic colleague Mateusz Bański. There were 3 of us at the beginning and for a long time we didn’t exceed 10 people. Now, we are 25 people with 19 R&D members and 9 PhD on board. At the beginning we were funded based on our own money and from commercial service of synthesis of various QDs.

In Poland the number of VCs who can help to go through “death valley” who can accept the high risk of a project like ours is very limited. Fortunately, in Poland, we have an alternative stock exchange market, called New Connect, which helps companies such as QNA get to the next level. So, in the second half of 2023 we closed successfully pre-IPO and in December 2023 became a public company. Now, as a public company, we are in the process of transitioning from New Connect market, to main fully regulated market on the Warsaw Stock Exchange

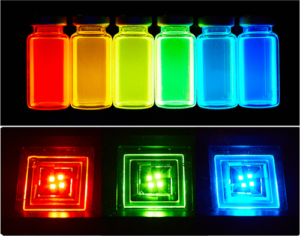

We focus mainly on blue light emitting QDs for electroluminescent devices. We also develop inks based on our blue QDs which can be used for a special kind of MicroLED.

Can you tell me more about the special kind of MicroLED that would use your photoluminescent QDs?

In this case one would use UV MicroLEDs in the backlight. There are many advantages to this. When you use UV, the absorption of red and green QDs increases significantly. In addition, you would need to have blue QDs though. Another big advantage is that there is no blue light leakage. Using UV light avoids this problem as only one filter for UV light is required. There are some advantages at the small pixel sizes of UV MicroLED compared to blue ones from an electronic performance perspective. These are three main advantages to using UV MicroLED with blue, red, and green QDs.

Does QNA work with Cd-based materials or heavy metal-free materials?

Our PureBlue quantum dots are Cd-free materials. No cadmium and no lead was our goal from the beginning. We also select our technological approach to minimize the harmful effects of processing.

Blue QD-EL and photoluminescent blue QDs with Cd-free materials are some of the most challenging colors, applications, and materials sets I can think of. Why did QNA go after these materials and applications first?

In 2017 we found out that some people start to work seriously on QD-EL technology because the potential amazed us. But we also knew that to make this technology commercialized, you need a very high-quality quantum dot first. We knew that the bottleneck for QD-EL technology would be blue QDs, as blue QDs are one of the biggest challenges in QDs synthesis. So, there was a big business opportunity, exciting technology to develop, chance to contribute to displays development in a visible way and a big risk, therefore we couldn’t resist to take this challenge and develop a product with a big market need in future. We knew there were other companies working on red and green, but only two companies working on blue at that time. As a small company we felt this could be a good technology to start on to open the door to cooperation with other companies and help them do great things. Of course, this brings with it risks and challenges.

Speaking of challenges, what is it like being a small startup in Poland?

Startups are still a new way of business in Poland. This means there are a lot of opportunities but also a lot of challenges on many levels and not so many people are open to these challenges. This means you can only move forward by working close with your entire team, together taking lessons from failures and together enjoying the successes. The number of problems we had to solve over these years together is tremendous, so I am quite confident about getting to our recent goals. But achieving ambitious goals takes time.

To be honest, funding was and still is the most important challenge for us. These materials are difficult to develop, as is working with the display industry. You need time to solve the problems and build trust with your partners, and you need money for this.

What products are available now from QNA?

Regarding photoluminescence we deliver PureBlue.dots which can emit light with a peak position from 445 up 460 nm. We can deliver this material in several types of solvents such as toluene, octane, and others. We can also deliver in monomers and in the form of UV curable ink. We also offer DeepBlue.dots with the emission from 445 down to 420 nm which also can be delivered in different solvents and monomers.

How do you differentiate your products from other QD companies?

First of all we do heavy-metal free QDs which makes our materials different from the few other companies working on blue Cd-based QDs. Secondly, what I can say is that our technological approach we are using for synthesis is quite unique. Also, we develop our own unique purification process which allows us to keep reproducibility and quality of our materials high. Our approach also allows us to customize our materials to the needs of our customers relatively easily. Thirdly, we also provide the final product to our clients. From the core, shell, ligand, surface engineering, and inks allow us to ensure the client gets what they want. There is an advantage to having this all under one roof instead of using multiple companies. We can customize our inks to the needs of the device and printers requiring certain rheological properties, which sometimes requires going back to the QD design itself.

The last aspect is that for sure we are different compared to other startups. Many focus on material development only. In QNA from the very beginning we were also focusing on technology development and scalability. In consequence, early this year we build our first pilot line which is now under optimization. This allows us to ensure our customers that we will be prepared to take our material to the next scale in short time if needed. Our goal is to deliver a product, not just a sample.

Can you share some recent results of your development on blue QD-EL, if you are willing to share?

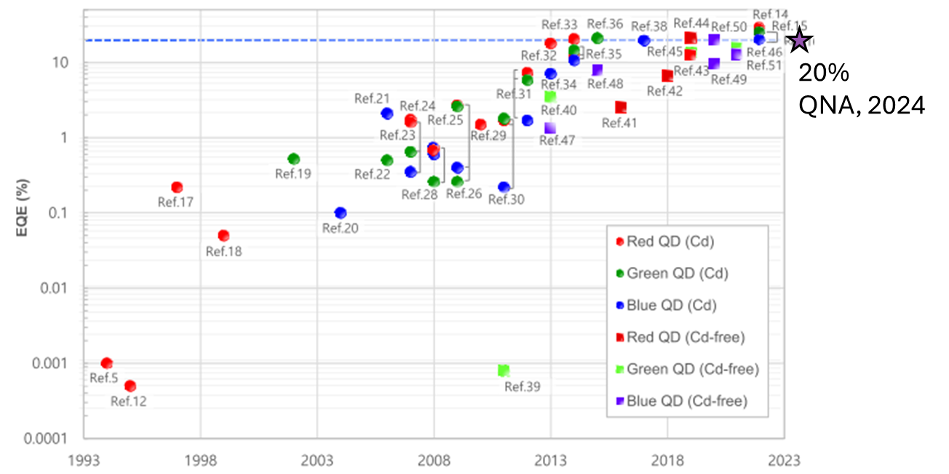

As you know, the device performance depends on many different materials and processes, some of which are well-beyond the QD properties. Some quantum dots companies decided to develop their QD-EL devices in house, which is good for speed, but there is a risk that you don’t get to the next level since there are so many other components to optimize. So we focus on working with external partners experienced in this field. We cooperate with many partners to solve the problems statistically. We send our materials to partners and improve it based on their feedback. This process we only started about a year ago achieving initially ~1% EQE, but even in this short time I am happy to tell you that we have started to get results from our patterns with EQE = 20%. This was, for us, a very important result as we know it’s possible to get high efficiency using our materials.

Impressive EQE numbers, thank you for sharing this with us. Can you speak to lifetime of the devices that were tested?

It was important to get first the confirmation that with our QDs we can get a high EQE and device reproducibility. Now is the time to play with ligands and other QDs parameters to improve the lifetime at 1000 nits. The next step for us will be to combine a high efficiency and long lifetime of blue QD-EL devices. I hope I will be able to give you some exciting news next year before SID 2025.

What can we expect from QNA in the future?

Better QDs in larger quantity. Significant progress in UV curable inks based on our blue QDs. These are our goals. We will also be working to develop more device data, not only EL devices, but also with the UV-MicroLED concept. It will be interesting to see how this approach compares to a more traditional blue MicroLED approach. We are also hoping for more cooperation. QD-EL is a fascinating but complicated area, and without close cooperation between materials companies and display makers it is going to be very hard to bring QD-EL to the market in a short period of time. We are hoping to have more friends working on this and we are always open for cooperation.

Thank you Artur, it was a pleasure speaking with you and I wish you the best of luck and thank you for sharing your results with me.

Thank you Peter for having me.

After my discussion with Artur, I dug into the data to see how QNA’s results stack up against the competition. It turns out 20% EQE is quite good for blue QD-EL devices. In a recent review article, authors from Samsung summarized the status of the EQE of QD-EL devices in one graphic showing steady improvements in the past few decades. I took the liberty of adding the data point from QNA to this chart, and as you can see it shows that 20% EQE is in line with the best performing blue Cd-free data points on the chart (purple squares).

In general, historical data like this gives me hope that technologies like QD-EL will continue to advance to reach commercialization stage. And it’s sometimes the small companies like QNA that can help make this happen.

I’ll be at SID Display Week 2024 all this week to see what other developments have taken place in the display industry. Hope to see you there!

Peter Palomaki is the owner and chief scientist at Palomaki Consulting. He is widely recognized for his display teardown videos and scientific approach to helping clients. He utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.