Porotech, which specializes in GaN-based semiconductor technology, has formed a partnership with Powerchip Semiconductor Manufacturing Corp. (PSMC), a semiconductor foundry in Taiwan, to focus on MicroLED production for display applications. The collaboration aims at using Porotech’s uLEDoS and dynamic pixel tuning (DPT) technologies, combined with PSMC’s expertise in semiconductor wafer manufacturing. This alliance is expected to enhance the commercialization of MicroLED displays for consumer applications.

Porotech, headquartered in Cambridge, UK, with facilities in Taiwan and the USA, wants to lay claim to developing small and efficient MicroLED chips that emit the full visible color spectrum from a single GaN material system. DPT is a display technology that allows a single pixel to produce light of any color in the visible spectrum based on the drive signal. This eliminates the need for separate red, green, and blue subpixels to create a full color display.

It works by tuning the drive signal to adjust the color output of each pixel. This tuning can be done very quickly allowing for dynamic adjustments. Porotech claims that DPT simplifies the manufacturing process for MicroLED displays used in AR/VR headsets by removing the need for a complex color conversion step. This improves yields and lowers costs. It also enables display designers to trade off between resolution and brightness and efficiency. The expectation is that replacing RGB subpixels with larger DPT pixels can increase brightness 3-5x while maintaining resolution. Or resolution can be increased 3-4x by shrinking pixel size while maintaining brightness.

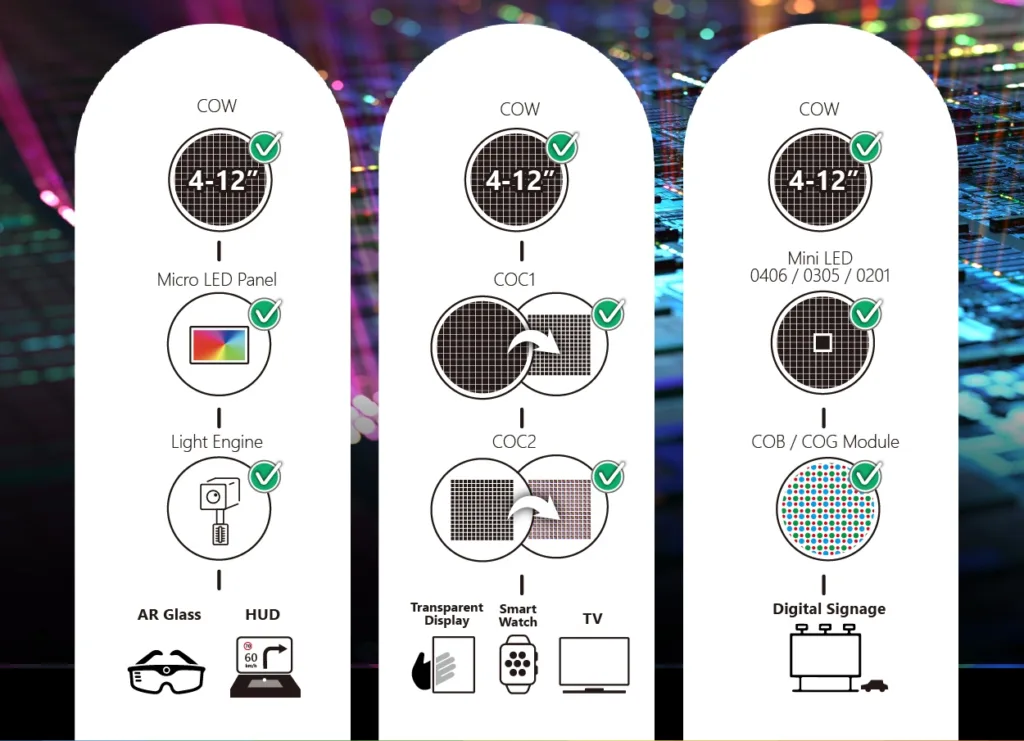

PoroGaN is an exclusive MicroLED material developed by Porotech using a patented formula. It is an InGaN material that allows for epitaxial growth on large 4-12 inch wafers, according to the company, while providing more manufacturing flexibility compared to the typical 4-6 inch wafers. PoroGaN enables all RGB colors to be made from InGaN, whereas normally the red requires a different material like AlGaInP. By using InGaN for all colors, the manufacturing process is simplified by having a consistent material set. This reduces costs by integrating optics, simplifying inventory, and improving conversion yields.

Additionally, PoroGaN’s InGaN red material has better thermal stability compared to AlGaInP red. This results in less brightness degradation over time and with higher temperatures. It also enables better color accuracy and consistency across RGB colors.