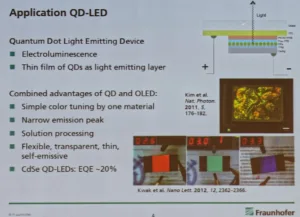

Christian Ippen is from the Fraunhofer IAP and he also talked about QDs, which the Fraunhofer is researching. His introduction covered some of the ground that 3M had been over. The Fraunhofer uses an OLED-type structure to directly excite the QDs with electricity, rather than using QDs for colour conversion as 3M is doing. Work is being done in Korea as well as Germany in collaboration with KIST. Broadly, the Fraunhofer approach is to use an OLED-type device structure, with QD materials replacing the OLED materials. Materials can be solution processed.

Ippen said that the QDs based on CdSe should be able to reach 20% EQE. As Patz had said, the narrow emission peak of the QDs depends on the distribution of particle sizes.

CdSe is used by QDVision and Nanosys as the main material for QDs, but Fraunhofer wants to use other materials. The organisation has worked mainly on Indium Phosphor (InP) which is “not so difficult” to make, Ippen said, and can be tuned by controlling the production conditions.

Synthesis of the compounds is by a “heating up” method with surface passivation.

There are different structures possible with a “conventional” approach, but there is also an “inverted” structure that can use oxide layers (zinc or magnesium oxide) After making some devices, the next move by the Fraunhofer was to try to optimise the colours. It turns out that the particle growth is an important part of the process for getting the right size of particle.

InP could not be used for blue because the particles are too large, so a ZnSe QD has been developed for creating blue. At the moment, the maximum brightness of the blue QD devices has been 30 cd/m2 and at 0.02 cd/A.

Fraunhofer is working with KETI and has made flexible, transparent QD segmented devices and passive matrix displays have been fabricated.

One of the main challenges is optimising the FHWM to control the size distribution.