At CES, I was impressed with the development-stage company Novasentis and its electro-mechanical polymer (EMP) haptic actuators. Yesterday, Novasentis and Kemet Corp. jointly announced they would collaborate on the production of film-based haptic actuators for wearable devices. “Novasentis will provide the core technology and haptic actuator film,” the announcement said, “whereas Kemet will develop the manufacturing process for final assembly.”

Kemet is a well-known global supplier of electronic components, particularly capacitors, and they currently manufacture a line of polymer capacitors. Kemet is a good fit for Novasentis because Novasentis actuators incorporate 30-50 film layers, and some of Kemet’s capacitors also use dozens of film layers. Kemet also manufactures conventional piezoelectric actuators, so that business isn’t new to them.

Kemet SVP and CTO Philip Lessner, said “Our expertise in film-based capacitor manufacturing is a perfect match for the needs of the Novasentis haptic technology. We will be able to use our existing manufacturing lines to develop mass production quantities of actuators.” Okay, but is there something more strategic in this than a logical addition to Kemet’s portfolio of product lines? Yes. “The collaboration with Novasentis allows Kemet to further its reach into emerging markets including wearables,” Lessner said.

What’s so interesting about EMP? After all, phones and smart watches already contain haptic actuators. The actuators in most of these devices produce their vibrations by using a tiny rotary motor to spin an eccentric rotating mass (ERM). This vibrates the entire device at a single frequency of vibration. This is obvously useful as silent ring or alert, but it constitutes a very limited haptic repertoire. In addition, although I just said the motors are tiny, they wind up being very large and heavy in the context of a smart watch — and somewhat large and heavy even for a smartphone.

Apple has improved on the ERM approach in the iPhone with its Taptic Engine, which is a linear resonant actuator (LRA). This approach delivers a faster a more subtle output with, I have been told, a choice of two frequencies instead of one. However, Apple’s LRA is still (in the context of portable devices) large, heavy, and probably expensive.

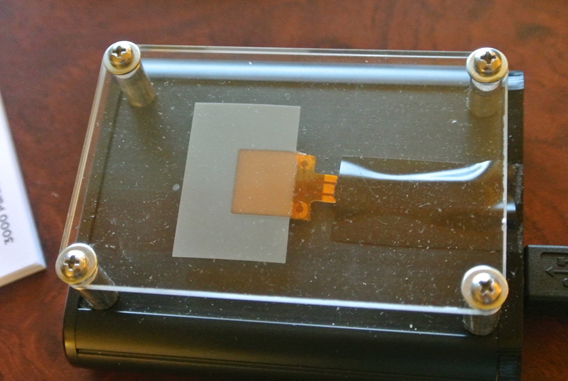

This demonstration of the Novasentis polymer-film haptic actuator was shown in the company’s suite at CES 2016. The actuator has a polyimide-like orange color. It is attached to a card to make its movements more obvious. (Photo: Ken Werner)

This demonstration of the Novasentis polymer-film haptic actuator was shown in the company’s suite at CES 2016. The actuator has a polyimide-like orange color. It is attached to a card to make its movements more obvious. (Photo: Ken Werner)

With that background, we can now appreciate the benefits of EMP actuators: They are light, very thin (150 micrometers thick), reasonably small in footprint (10x10mm), and can deliver a haptic stimulus at anywhere from zero hertz to 20kHz. One of Novansentis’s concepts is to place two of them in a smart watch’s band, one on either side of the watch. This provides directional information. Think of silent turn-by-turn directions depending on which actuator was actuating. In addition, a large range of information can be communicated with different frequencies, intensities, crescendos, and frequency sweeps. I got a very small taste of this in Novasentis’s CES suite, but that was a simple technology demo. Product designers will have a field day with this new palette, and will need to call upon human-factors people, neuro-scientists, and, very likely, musicians for help.

Is there a downside? Yes. The Novasentis EMP device requires approximately 200 volts for actuation, but in our era of switching power supplies that should be manageable.

Novasentis and Kemet certainly think so. They plan to deliver production prototypes this summer, with volume production beginning in early 2017.

– Ken Werner.

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. You can reach him at [email protected].