Now that consumer electronics companies have decided the world is hungry for smartphones that fold, display makers have developed an equal appetite for ultra-thin glass (UTG). Since it is glass, UTG has admirable optical qualities for the front layer of an OLED display, and it’s ultra-thinness makes it flexible. In addition UTG, like thicker glasses, is an effective moisture and oxygen barrier, without which OLED displays rapidly deteriorate.

In pre-historic times, in order to save weight, the cover glass and substrate of phone displays was thinned from the then-standard 0.7mm thickness to 0.3 or 0.4mm by etching the glass, but this thinned glass was many times thicker than UTG. Surprisingly, LG’s well-publicized but little-sold rollable OLED-R TV is also made on glass etched down from the now typical 0.5mm to an UTG thickness of 70µm, as reported by Bob O’Brien and Jayden Lee in the March 23 issue of DSCC Weekly Review. O’Brien and Lee went on to say they believe the thinning process contributes to the very low yield on these screens. Clearly, this is not the way to manufacture UTG in high volume and at relatively low cost.

At the moment only one glass company has this capability: the 136 year old specialty glass maker Schott AG of Mainz, Germany. Schott has been making UTG since the mid-1990s. One of the early applications was cover glasses for microscope slides. Schott is now heavily involved in making UTG for foldable OLED displays for smartphones, and reached out to Display Daily to tell us — and you, dear readers — what they are doing and with whom.

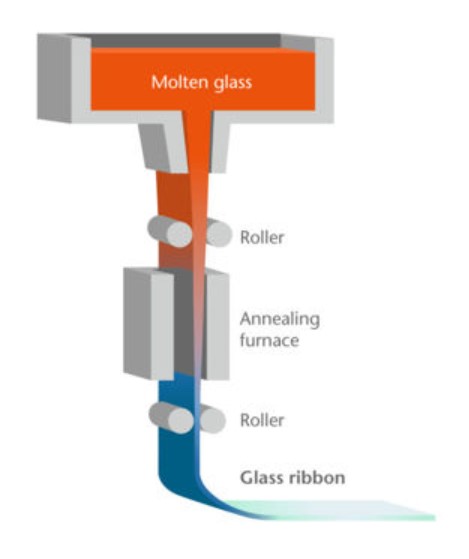

Fig. 1. Schott’s down-draw process produces a ribbon of glass with surface roughness of less than 0.5nm and thickness from 1.1 to 30µm. (Graphic: Schott AG)

Fig. 1. Schott’s down-draw process produces a ribbon of glass with surface roughness of less than 0.5nm and thickness from 1.1 to 30µm. (Graphic: Schott AG)

Uniquely, at least for now, Schott can make UTG in commercial quantities using a melting process, specifically a proprietary down-draw process that directly produces an ultra-thin glass ribbon (Fig. 1). Schott calls its UTG line Xensation®, and the flexible version, Xensation Flex, can attain a bending radius less than 2mm. Shott calls Xensation Flex “the first generation of foldable glass.” Mathias Mydlak (Schott’s Global Business Development Manager for Special Flat Glass & Wafer), said via email that “Schott is the only company to provide ultra thin glass which can be [chemically] toughened.

Schott is currently delivering Xensation Flex to the Korean company Dowoo Insys, which “performs the cutting, edge processing, chemical strengthening, and cover film lamination,” reports DSCC’s Ross Young. Samsung is using the final cover-glass assemblies in its Galaxy Z Flip and other foldable phones. I have been skeptical of the market appeal of foldable phones, particularly at their very high prices, but Young reports that shipments to Korea may already have exceeded 100,000 units, with global shipments perhaps have reached 500,000, which numbers are greater than Samsung’s expectation.

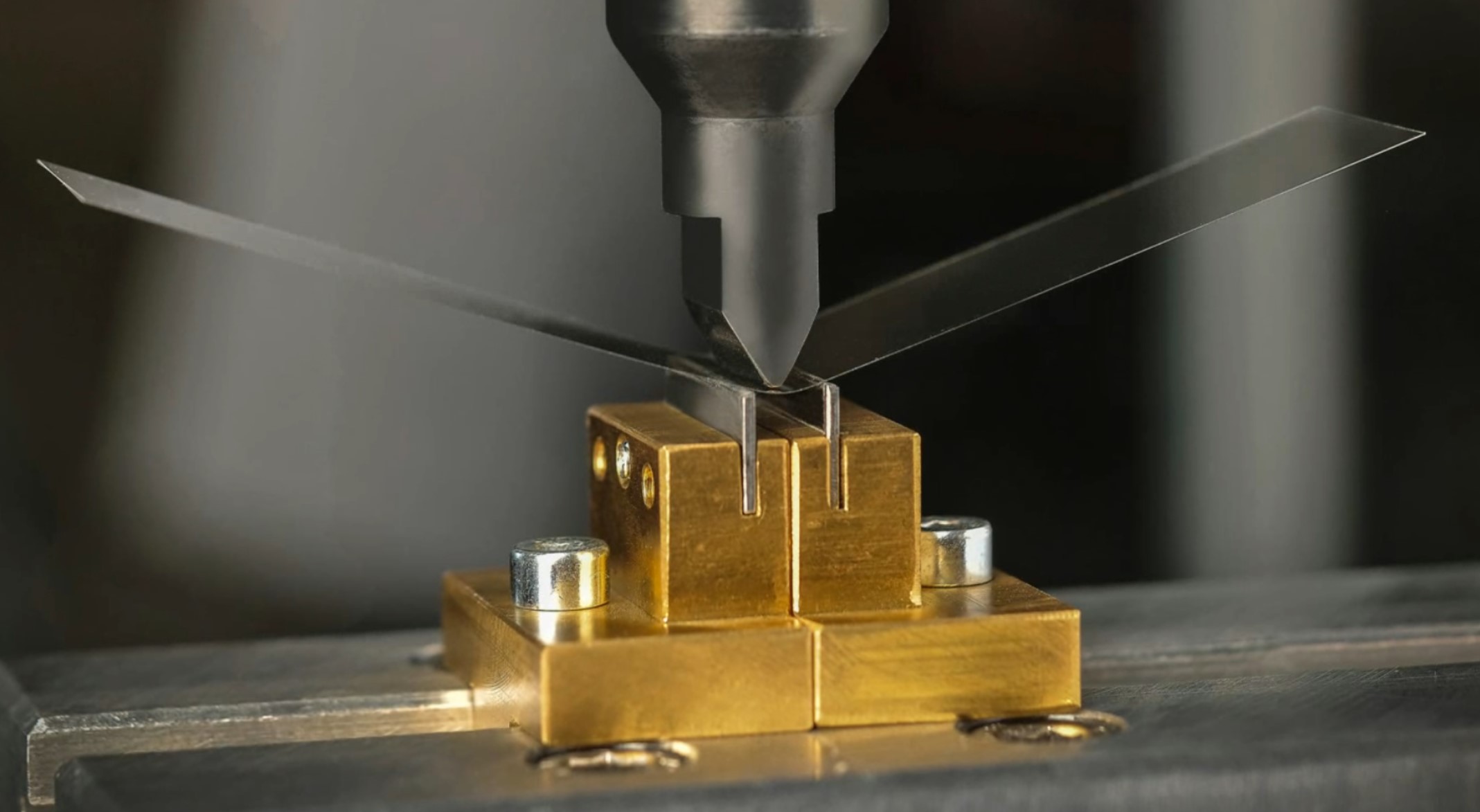

Fig. 2. An impact test on Xensation UTG. (Photo: Schott AG)

Fig. 2. An impact test on Xensation UTG. (Photo: Schott AG)

Schott’s Mydlak said that non-flexible Xensation cover glass is being incorporated in phones by Vivo and in the OPPO Smart Watch.

With the market established, both major and minor glass makers are working to catch up. I reached out to Corning, the most major of the major glass makers. Marketing Communications Manager Sarah Pakyala said this via email:

“What I can share is that Corning believes that today’s material sets of plastic options and glass options do not meet all of the desired attributes of a bendable device. Corning is currently working on several glass-based products that may be the ultimate solution. To date, the technology has demonstrated success in a range of thicknesses (30-100µm) in R&D. This developmental glass-based solution can bend >200,000 times without damage while maintaining its flatness. This is compared to alternative materials which can begin to crease and deform significantly at around 200,000 bends. We are working with our customers on this challenge and are currently sampling our development glass with them to optimize the product for their design requirements. While we can’t put a specific timeframe on it right now since the glass is still in development, we believe that our glass solution will be ready in the next 12+ months.”

Schott does not seem intimidated. Said Schott PR account executive Lexie Harkness:

“Schott’s extensive UTG portfolio, now officially housed under the Xensation product line, is paving the way for the future of flexible glass in mobile displays and could loosen Corning’s grip on the market.

(KW)

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices, automotive, and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected] or www.nutmegconsultants.com.