Verlase Technologies has patented its Chromover wavelength conversion technology. According to the company, Chromover enables full-colour micro-LED arrays for near-eye displays. The technology is said to be able to replace phosphors and quantum dots (QDs) for colour conversion in ‘key applications’.

Chromover can convert colours from inexpensive and widely-available blue and violet light sources (such as LEDs and lasers) to ‘any colour in the visible range’, such as optimal reds and greens. The colour’s spectral characteristics can also be tailored to the application; this means that the output can be designed for a laser, LED or hybrid; a single-colour of RGB projector light source; or a multi-colour micro-LED array.

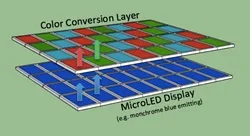

Near-eye displays present a challenge in the realistic colour projection of images onto a person’s field of view, writes Verlase. Most microdisplays used in such products today are OLEDs, which produce good colour but have limited brightness and lifespans. Displays using micro-LEDs would not face these challenges. However, until now, they have been monochrome; the phosphors typically used in LED colour conversions do not scale well to small size and have thermal issues; QDs have similar problems.

Chromover is a wafer-scale thin film technology using a resonator cavity, surrounding semiconductor quantum wells. The structure is designed to emit light at a desired wavelength when pumped with a known source, such as LEDs or lasers. The inorganic resonant structure ‘dramatically’ increases absorption of the pumped light; Verlase claims that it can withstand much higher optical power densities than other approaches. The output can be emitted as a spontaneous unidirectional light as an LED, to lase in stimulated mode as a vertical cavity surface-emitting laser (VCSEL), or an in-between state. The third option features tailored spectral properties to mitigate speckle.

A colour conversion layer for microdisplays can be manufactured as a passive, pixellated microarray, down to sub-10µ, with RGB colours per pixel as required. Conventional wafer-scale processes are used to form a monolithic film structure that can be integrated with active micro-LED arrays.

Verlase says that the technology can scale to larger displays, including projectors (from pico to large venue) and edge-lit screens. Power can be scaled for bright projectors up to cinema range (30,000 – 50,000 lumens) for high-intensity laser pumped applications, such as car headlights.