The auto industry is comfortable with LCDs. They survive 150,000+ miles of over-the-road vibration and pounding, and tolerate temperatures from Siberian winters to Arizona summers. (Well, most of the time. Mazda 6 sedans circa 2004 were well known for TAB failures in their monochrome combined climate-control/audio-system/clock displays, but the industry has learned a lot since then.) And pricing is attractive.

But the industry would like a better contrast ratio and and improved readability in high ambient light. “OLEDs!” screams the multitudes. (I can you hear you now.) But OLEDs still aren’t stable over the required automotive temperature range, and burn-in is a problem at the peak luminances OEMs and Tier 1 suppliers require. Some full-color OLEDs may soon be appearing in commercially available vehicles, but sources tell me this is a matter of down-specing, not improved materials.

Not surprisingly, vehicle display makers have explored LCD backlights enhanced with quantum dots and miniLEDs. But I was surprised to find two papers on dual-cell LCDs at the SID Vehicle Displays and Interfaces Virtual Conference sponsored by the SID Metro-Detroit Chapter on October 14th and 15th.

TV-sized dual-cell displays look superb head on, but they have issues with moiré patterns off-axis, reduced luminance off-axis, weight, thickness, and power consumption. As a result, their one successful application so far is in production monitors, where their OLED-like contrast and high luminance make them an ideal choice, and their deficiencies don’t matter. But they would matter in automotive applications, unless there’s a solution.

In Paper 5.3, Jonathan Huggins (Senior Engineer, FlexEnable, Cambridge, UK) discussed FlexEnable’s efforts to bond two of their flexible organic TFT (OTFT) displays into a very thin, flexible, dual-cell display. A dual-cell OTFT can achieve contrast ratios of a million to one, Huggins said. (Flexenable Boosts Dual LCD for Automotive (and….)

For several years FlexEnable has been reporting on its OTFT displays. Since the OTFT processing temperature is less than 100°C, the matrix can be fabricated on tri-acetyl cellulose (TAC) instead of glass. Since TAC is used for polarizers, it is very widely available and it is inexpensive, costing less than $1/m². An OTFT display was integrated into the Novares Nova Car #2 demonstaration vehicle in 2019, and small demonstration displays have been exhibited widely.

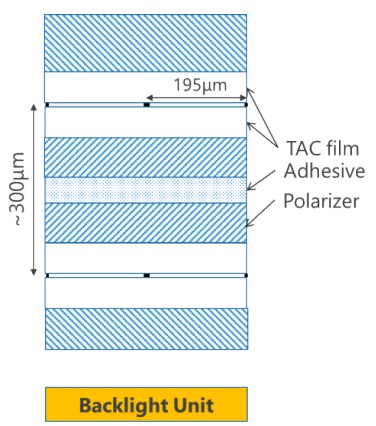

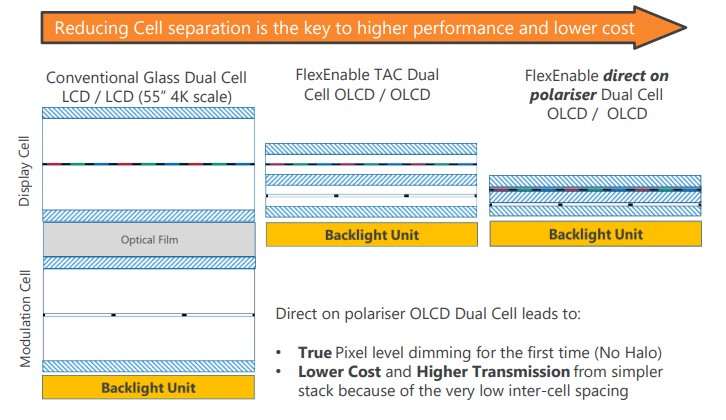

Now the company is working on a dual-cell version. Dual-cell problems, said Huggins, have been thickness, weight, brightness off center, mura, and moiré, all of which are related to the large separation between the modulation and display cells caused by the thick glass substrates. The entire thickness of the dual test structure is ~400µm, with an intercell separation of ~300µ (Fig. 1). The test structure black state is 0.015 nits and the white state is 3987 nits, said Huggins, for a contrast ratio of 266,000:1.

1. Since the TAC substrates of FlexEnable’s dual-cell test structure are only 40µm thick, the entire structure is only about 400µm thick with a 300µm inter-cell separation. (Figure: J. Huggins, FlexEnable)

1. Since the TAC substrates of FlexEnable’s dual-cell test structure are only 40µm thick, the entire structure is only about 400µm thick with a 300µm inter-cell separation. (Figure: J. Huggins, FlexEnable)

Huggins added that intercell separation can be further reduced to about 100µ by fabricating the OTFT matrix directly onto an ultra-thin TAC polarizer substrate. That would make the intercell separation “less than the pixel pitch.”

2. The current test FlexEnable test structure (center) offers a much small inter-cell separation than does a conventional glass-based structure (left). The next step is to fabricate the OTFT matrix directly on the polarizer film, for an inter-cell separation of about 100µm, less than the inter-pixel separation. (Figure: J. Huggins, FlexEnable)

2. The current test FlexEnable test structure (center) offers a much small inter-cell separation than does a conventional glass-based structure (left). The next step is to fabricate the OTFT matrix directly on the polarizer film, for an inter-cell separation of about 100µm, less than the inter-pixel separation. (Figure: J. Huggins, FlexEnable)

Visteon Also Working on Dual-Cell

Paul Weindorf is Display Technical Fellow at Visteon Corp. (Van Buren Twp., Michigan), one of the world’s major Tier 1 automotive suppliers. In paper 5.5, he discussed his company’s development of a dual-cell LCD it calls µZone™.

Weindorf noted that typical automotive TFTs have a background leakage of about 1 nit, which is the inevitable consequence of having a 1000-nit display with a 1000:1 contrast ratio. “OLED technology provides a black background,” said Weindorf, “but suffers from image burn-in, low luminance, and high cost. Full-area local dimming provides some black background improvements, but suffers from halo artifacts. Dual cell technology has excellent black background performance, but has historically suffered from large power dissipations until now…” Visteon’s focus in developing µZone was reducing power consumption.

Weindorf noted that the architecture produce a contrast ratio of greater than 100,000:1 on-axis and greater than 10,000:1 at a viewing angle of 60º horizontal.

Windorf was very cagey about revealing architectural details of the display but said that Visteon increased system efficiency by modifying the inter-cell diffuser, using a proprietary light-control method, improving the backlight efficiency, and applying special driving algorithms to the monochrome TFT to smooth edges, provide optimized and gamma function, and eliminate color-cell light leakage.

Most dual-cell technologies require 2X to 2.5X the backlight power of a single-cell LCD. The µZone display requires only 1.3X while improving the color gamut to 96% NTSC with an optimized color filter), compared to a gamut of 85% NTSC for the single-cell display that is currently in production. Weindorf concluded by immodestly saying, “µZone dual cell technology has solved the power dissipation entry barrier for automotive applications.”

I think we can make a high-altitude comparison of these papers by saying that FlexEnable directly attacks the cause of dual-cell artifacts by reducing the intercell separation, while Visteon compensates for some of them with its special driving of the monochrome cell. I would want to look closely at the Visteon display to see if its edge-smoothing produces artifacts of its own. On the other hand, Visteon is basing its µZone display on current production, and we might therefore expect it to reach volume production before FlexEnable.

But this is speculation. The matter will be resolved when reality raises its ugly head, as it always does. (KW)

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices, automotive, and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected] or www.nutmegconsultants.com.