During the last few days several news outlets have reported on a new wonder glass developed by Japanese Scientists that is “nearly unbreakable”, “almost as strong as steel” and “will be ready for commercialization” within five years.

As a long time glass guy, I surely wanted to know what this is all about. Spoiler alert – there is no evidence that any glass maker should be alarmed about a major shift in glass making based on these results.

The background of the research as well as the results were published in Scientific Reports in detail and describe what the authors (Gustavo A. Rosales-Sosa, Atsunobu Masuno, Yuji Higo, Hiroyuki Inoue, Yutaka Yanaba, Teruyasu Mizoguchi, Takumi Umada, Kohei Okamura, Katsuyoshi Kato & Yasuhiro Watanabe) wanted to achieve. Here is the short version.

Glass is an amorphous solid or a frozen liquid, which pretty much means the same thing. In scientific terms it acts like a solid material and has the structure of a liquid. Characterizing glass materials differs in some way from other materials, as the behavior of glass is somewhat unique. For the most part, one function of glass is that it is typically transparent in the visible region of the electromagnetic spectrum allowing the use as windows and the like. One could actually think of the front panel of a display as a window that allows us to see the image created by the underlying electro-optical structures.

The differences between the glass types in production today are based on the different compositions used in the synthesis, but most current glass types are highly tuned to the demand of specific applications. Window glass is cheap and very flat to avoid optical distortions; display glass combines a number of properties that are important like controlled thermal expansion, surface quality and many others. To be clear, the surface quality depends on the manufacturing process not so much on the composition. However, one may argue that the composition defines the melting temperature which has a great impact on the manufacturability of the glass.

If you feel that I am making it sound that it is hard to come up with something new, you are right. It is very hard. Typically, glass development proceeds by small steps towards a better glass composition and steps in the manufacturing process that includes material development in the refractory materials containing the glass melt. Overall, glass development is a very capital intensive process development and it is very rare that we see a big leap in glass manufacturing, although one big jump in glass manufacturing was the introduction of float glass many decades ago.

The new glass type proposed by the Japanese group is a play on seeing how much stronger a glass can get. Strength in this context is defined by the Young’s Modulus and the Vickers hardness. From a material standpoint, the Young’s Modulus describes the strain a materials shows in the direction of an applied stress. In glass materials, this material constant is influenced by the atomic packing density and the atomic bonding strength (dissociation energy per volume). It is known that alumina bonds have high dissociation energy, so it seems logical to try to put as much alumina in glass composition as possible. Unfortunately this creates other issues for glass makers, such as a high melting temperature and a higher tendency to crystallization.

The research group overcame these issues by adding roughly half of the composition as tantalum oxide (Ta2O5). In addition they melted the pellets in mid air by firing CO2 lasers at the particles. At around 2,000°C the powder formed a molten glass that was quenched at very high rates (300°C/s) and later annealed at a lower rate after reheating to just above the Tg (glass transformation point). If this does not sound like a cost effective manufacturing method, you are spot on.

Their experiments resulted in small glass like pellets that were used to measure the physical properties. The results showed the expected trend of a very high Young’s Modulus (158.3 GPa) and Vickers hardness of 9.1 GPa. These values are at the high end of all glass types and would be great for applications like smartphone cover glass as suggested by some articles. On the other hand, the new material also has a high density (6 g/cm³) and high refractive index of 1.94. Neither is a much desired property in a cover glass.

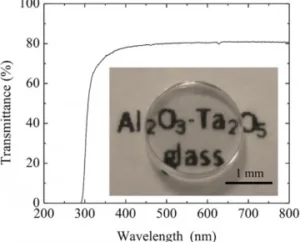

As the image shows, the new glass has a high internal transmission based on the lack of any impurities over a wide range of the visual spectrum. The UV edge of the transmission edge may actually be a little too wide open, as UV photons may lower the life expectancy of the underlying display components.

All in all this seems to be a case where some material properties of a new glass type induced wishful thinking among some analysts, without looking at the complete picture. While such glass types may have perfect properties for some applications, I just don’t see this for display glass in general. Just the price pressure alone will basically eliminate this option.

From my perspective this was a great story about the display glass that is “nearly unbreakable”, unfortunately the reality is telling us something very different. As I said before science is often such a spoiler for a great story. (NH)