SolidEnergy Systems Corp. (Waltham, MA), a start-up that spun out of MIT in 2012, is using innovative materials to develop an “anode-less” lithium-ion battery technology that allows for the storage of considerably more energy than is possible in current rechargeable batteries.

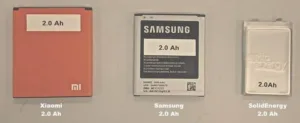

To put the company’s accomplishment into context, SolidEnergy’s prototype claims to store more energy than the battery in an iPhone 6, even though it is only half the size. Other examples of the battery’s energy storage capability are illustrated below.

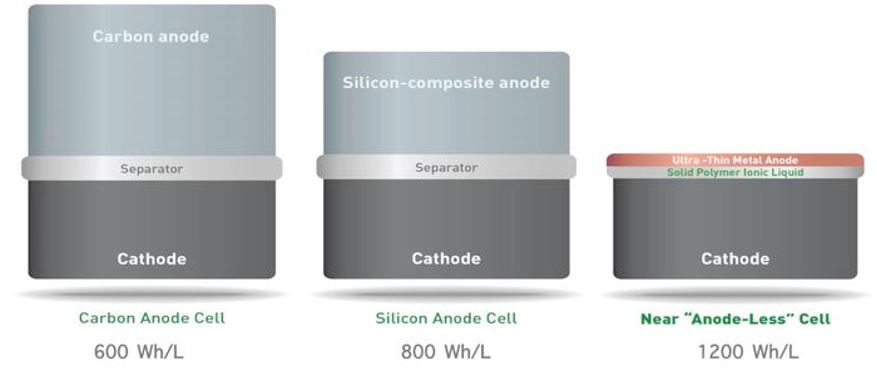

The means used to boost battery energy storage capacity is based on replacing graphite, the conventional electrode material, with an ultra-thin sheet of lithium+copper metal foil. Fragility in such a foil is reduced by applying a protective polymer coating to the foil. In addition, the new battery utilizes both a solid and a liquid electrolyte.

Although researchers have been investigating the use of lithium-metal electrodes in batteries for many years, up to now, various technical problems have prevented commercialization of the technology.

The first problem is that lithium metal tends to react with typical battery electrolytes. In such cases, compounds can be formed that trap lithium ions and prevent the generation of electrical current. This, in turn, results in a steady decrease in the energy storage capacity of the battery. The reaction also creates dendrites. These metal filaments can cause a short circuit that, in turn, can generate enough heat to ignite the flammable electrolyte.

The standard solution to these problems has been to replace the liquid electrolyte with a less reactive solid electrode. A solid material can also act as a physical barrier to prevent short circuits. The problem with this approach has been, however, that typical solid electrolyte materials do not conduct ions as well as liquid electrolytes with the result that battery performance is degraded.

SolidEnergy’s solution to this issue is to use both a solid and a liquid electrolyte. The solid electrolyte is applied to a lithium-metal foil. Given the thinness of the layer, ions do not have far to travel and, thus, there is little consequence to the fact that they move “slowly” while traveling through the solid electrolyte.

Once the ions transit the solid electrolyte, they enter the liquid electrolyte and move towards the opposite electrode. Unlike conventional liquid electrolytes, the material used by SolidEnergy is not flammable and functions well at room temperature. In addition, additives are included that prevent the lithium metal from reacting with the electrolyte and that, in turn, suppresses dendrite formation. Hence, the SolidEnergy approach seems to successfully address the short circuit/safety issues found with other approaches. Another important advantage of the SolidEnergy approach is that the company’s prototype is reported to have successfully demonstrated 100 recharge cycles while retaining 80 percent of its’ original energy storage capacity. This recharge capability is much more than competing, advanced Li-ion technologies. Nonetheless, the company is working to improve the manufacturing process, along with enhancements to the electrolyte fluid. The goal is to achieve the ~300 charge cycles that are needed for typical portable electronic device applications.

Another important advantage of the SolidEnergy approach is that the company’s prototype is reported to have successfully demonstrated 100 recharge cycles while retaining 80 percent of its’ original energy storage capacity. This recharge capability is much more than competing, advanced Li-ion technologies. Nonetheless, the company is working to improve the manufacturing process, along with enhancements to the electrolyte fluid. The goal is to achieve the ~300 charge cycles that are needed for typical portable electronic device applications.

This recharge capability result has been certified by A123 Systems (Livonia, MI), a battery manufacturer that is collaborating on this project. In fact, the prototype was assembled and tested at A123 Systems’ battery plant. SolidEnergy claims that this is significant because it makes the testing more realistic than the more common situation in which experimental batteries are fabricated and evaluated in a research laboratory.

The collaboration with A123 Systems is also indicative of a further advantage claimed for the SolidEnergy approach. Production of the new lithium-ion battery does not require new processing equipment and, thus, allows utilization of the existing, mature manufacturing infrastructure.

A video discussing the SolidEnergy Systems battery can be found at the end of this article.

The company hopes to bring its battery technology to a state of development such that it is suitable for portable devices by the end of next year. Beyond that, the company is working to negotiate arrangements to supply of the electrolyte and anode components to large battery manufacturers. – Arthur Berman

SolidEnergy Systems Corp., Qichao Hu, 617-972-3412, ??[email protected]