This week, I had the chance to catch up with SiliconCore, an LED developer and display maker that I have always enjoyed talking to. I have also always enjoyed looking at their displays – for me they are one of the ‘A’ list supplier of LED displays in terms of visual quality. But they also have their own technology.

I didn’t get to Infocomm this year, but some of the most interesting news announced there was from the company, so I set up a follow-up call with Jim Wickenhiser, Senior VP, Strategic Initiatives.

I didn’t get to Infocomm this year, but some of the most interesting news announced there was from the company, so I set up a follow-up call with Jim Wickenhiser, Senior VP, Strategic Initiatives.

The release that caught my eye in particular was the announcement that the firm had decided to license its Common Cathode Technology. As its name implies, SiliconCore was founded as a developer of chips and designed controller chips for laser diodes. It initially had a market in making chips to drive the lasers in DVD-RW drives – and these were in more than 100 million devices. During the development of the technology, it patented a method of driving the LEDs, called “common cathode” technology that is substantially more efficient than the common anode technology used by others. This is how the company describes the technique:

“In traditional Common Anode LED panel designs, the terminals of all 3 (red, green & blue) LEDs are wired together and an external ballast resistor is added in series with the red LED to maintain a constant voltage and equalize the voltage drop across all three LEDs. This subsequently reduces available space for the LEDs making fine pixel pitch harder to achieve, while it is also an additional heat source and accelerates the aging process and reduces the lifetime.”

Now, to correctly quote the oft-misquoted phrase, “the proof of the pudding is in the eating”. In SiliconCore’s case, its use of Common Cathode technology has allowed it to be a pioneer of very small pitch LEDs and also to achieve much higher brightness than most of its competitors. Very few of the narrow pitch makers can achieve high brightness at the same time as the fine pitches (which is why many focus their promotion on the pitch and not the brightness). Heat dissipation is a considerable problem if your LED driving is not as efficient as possible, and heat causes many issues with LED performance.

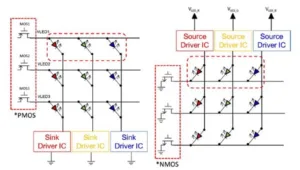

Macroblock showed this diagram of common cathode technology last summer

As is so often the case with displays, it’s not the brightest part of the images that is always the challenge, but the detail in the shadows which can be revealed when you have very accurate low grey levels (which is why there are so many very, very bright LEDs at trade shows). To handle accurate low level driving, the firm has its ZACH driving technology.

Now, part of the reason that I picked up on the news of the licensing was that founder, CEO and President, Eric Li has always highlighted to me that he wanted to build the company by keeping the technology ‘in house’. However, the momentum and market opportunity behind the LED display market has grown and grown and that means a big opportunity. Other companies have also been talking about their own common cathode methods over the last year or so (we reported on Macroblock‘s developments last summer). This increased activity has meant that there are good reasons for SiliconCore to exploit its ip.

I was reminded that some 30+ years ago, when others started to develop technologies to compete with its Trinitron CRT technology, Sony decided to license the aperture grille technology to Mitsubishi, allowing its competitor to develop DiamondTron CRTs. This made it a lot harder for others to develop a successful alternative, while making lower cost aperture grille CRTs available to monitor makers.

The other factor, as Wickenheiser acknowledged, is that there is a lot of interest in driving microLEDs. Although I have heard a number of developers saying “there won’t be a problem driving microLED”, my own experience is that there are always challenges in driving LED displays if you want high image quality. SiliconCore can licence its IP and patents for microLED driving, without any significant impact on its display systems business.

As well as the news about the IP licensing, the firm also launched the EZ-HD series of 110″, 130″ and 165″ monolithic displays (1-2-3 said Wickenheiser – one wall, two technicians, three hours to install). Despite costing from $100K and up, he told us that interest is very, very strong, especially for meeting rooms that want displays over 100″. The firm’s 0.83mm pitch Lotus display, which reaches 2,000 cd/m², was also launched. Most competitors at around this pitch are less than half this, in my experience. (BR)