The ET Times said that Samsung Display has changed from using excimer lasers to using diode-pumped solid state (DPSS) lasers to separate flexible OLEDs from the glass substrate that is used as a carrier (also known as laser lift-off LLO). The use of DPSS means that a curing process for the polyimide film is not needed and costs are reduced.

The OLED Association has said that AP System, which has previously dominated the market for LLO, has been developing machines to support DPSS, but that Philoptics has also been added to the list of suppliers and is increasing its share. Philoptics is reported by the OLEDA to be importing laser sources from Trumpf in Germany and to have won 70% of Samsung’s business for LLO in 2016, rising to 100% this year. The company is planning to expand its facilities to meet demand.

Lantechnical Service Co Ltd, of Japan, has developed a process by using non-laser de-bonding based on the use of silicon. The company said that it has run tests with international display makers.

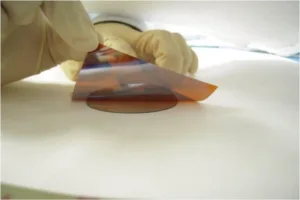

Lantechnical Service has non-laser debonding technology based on a silicon interlayer