A team of researchers headed by Xue-Mei Wen of Jilin University (Changchun, China) is developing means to improve the brightness of OLED devices based on using corrugated electrodes made of a metal alloy.

First, a few words of background information.

It is possible to achieve nearly 100% internal quantum efficiency in phosphorescent OLEDs. Unfortunately, a great number of the photons generated in the active layer remain trapped within the OLED structure. The loss of photons within an OLED is a result of several different mechanisms. The loss mechanism studied by the team in their current research relates what is called the Surface Plasmon-Polariton (SPP) mode. (A SPP wave is a type of surface wave that is guided along an interface in much the same way that light can be guided by an optical fiber.)

Previous research into OLEDs has shown that periodic corrugation of the electrodes could excite SPP resonance and extract photons trapped by the SPP mode within the OLED. Furthermore, that the period of the corrugation is a key factor in exciting SPP resonance at the desired light emitting wavelength.

Up to now, however, the various means investigated to produce periodic corrugations in electrodes have all required complex fabrication processes. As a result, the processes have been expensive and difficult to implement in commercial applications. Addressing these issues has been the focus of current research by the team.

An article reporting recent results of their investigations is entitled “Tunable surface plasmon-polariton resonance in organic light-emitting devices based on corrugated alloy electrodes.” It was published in Opto-Electron Adv 4, 200024 (2021). A copy of the article is available here.

There were two experimentally established observations that formed the starting points for the team’s research. The first was that, to effectively improve photon extraction, the excited SPP resonance should match the wavelength of the light emitted by the OLED. Second, that the excited SPP resonance induced by the periodic corrugations could be precisely tuned based on the material properties of the metal-dielectric interface.

Given these two starting points, the researchers developed a means to excite a tunable SPP resonance in OLEDs based on corrugated Ag-Al alloy electrodes having a fixed periodicity. More specifically, the means used to do so was to use nanoimprint lithography to introduce periodic corrugations on substrates. The Ag and Al were co-deposited. By allowing the Ag and Al deposition rates to be independently varied, it became possible to adjust the composition of the alloy.

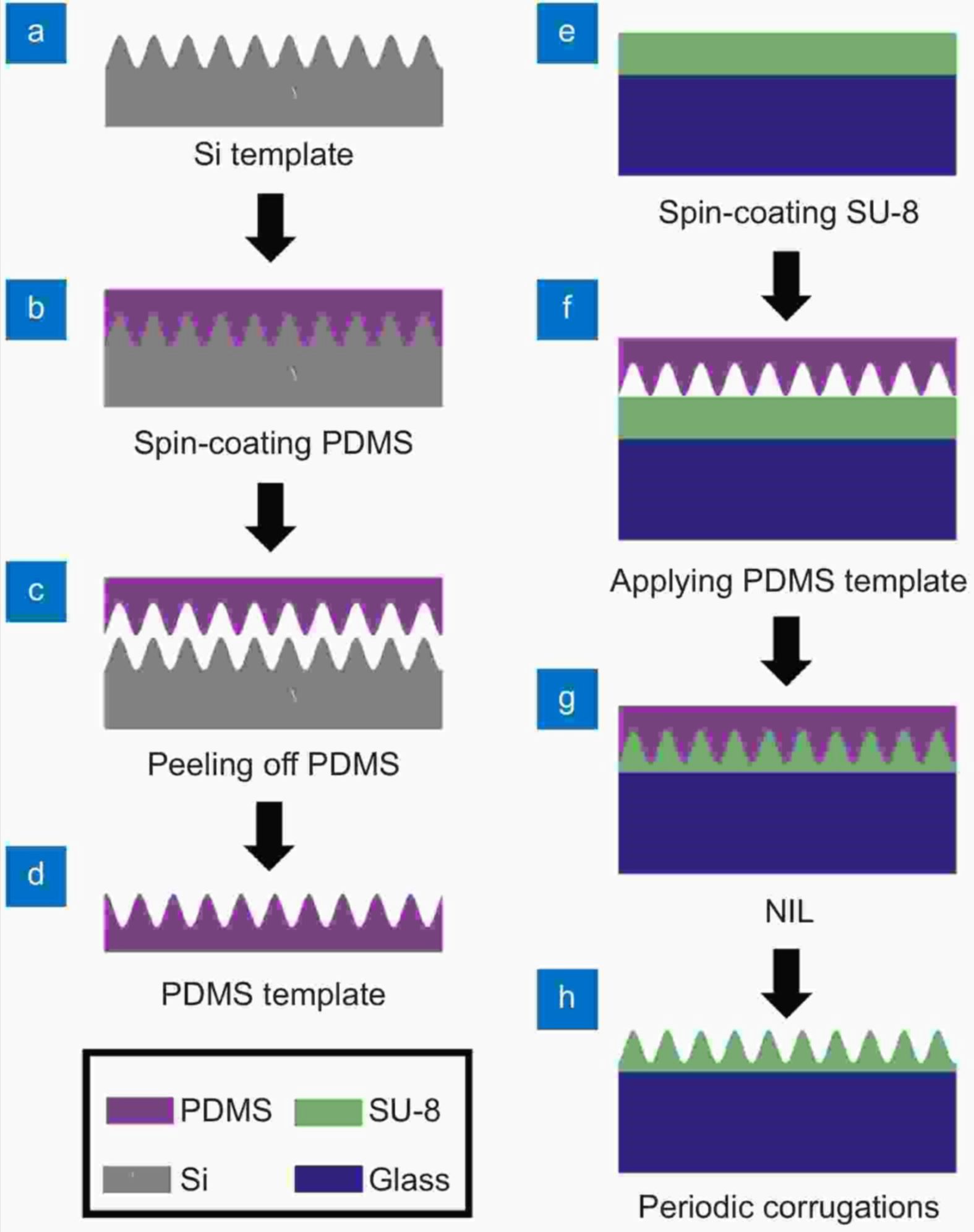

The process used to fabricate the periodic corrugations is illustrated in the figure below.

A graphic illustration of the process used to fabricate the periodic corrugations. (a) Si template with 290 nm periodic corrugations. (b) PDMS (an acronym for the chemical material polydimethylsiloxane) was spin coated on Si template. (c) Solidified PDMS film was peeled off. (d) The corrugations were transferred to PDMS template. (e) SU-8 (the name of a photoresist product made by MicroChem Corp.) was spin-coated on a pre-cleaned glass substrate. (f) Prepared PDMS template was placed on the SU-8 film. (g) NIL (an abbreviation for nanoimprint lithography) processes were applied. (h) The periodic corrugations were prepared on the substrate.

A graphic illustration of the process used to fabricate the periodic corrugations. (a) Si template with 290 nm periodic corrugations. (b) PDMS (an acronym for the chemical material polydimethylsiloxane) was spin coated on Si template. (c) Solidified PDMS film was peeled off. (d) The corrugations were transferred to PDMS template. (e) SU-8 (the name of a photoresist product made by MicroChem Corp.) was spin-coated on a pre-cleaned glass substrate. (f) Prepared PDMS template was placed on the SU-8 film. (g) NIL (an abbreviation for nanoimprint lithography) processes were applied. (h) The periodic corrugations were prepared on the substrate.

The article reports in great detail the materials and means of fabricating OLEDs using the new technology. In addition, extensive measurements were made of test OLED devices. The means used to obtain measurements and the results of the measurements are also reported in detail. In addition, the article describes and reports the results of theoretical modeling of device properties. The model was based on utilizing a finite difference time domain method.

The first top level result of the research into OLEDs fabricated with the new technology was that modifying the deposition rates of Ag and Al to change the molar ratio in the composition of the alloy used in the cathodes made possible a tunable SPP resonance in corrugated OLEDs – without changing the period of the corrugations. More specifically, the resonant wavelength of the excited SPP mode induced by a corrugated Ag0.909Al0.091 alloy cathode in test OLEDs was exactly consistent with the emission peak of the test OLEDs. Secondly, that photons trapped in the SPP mode were effectively out coupled and extracted. Due to the improved light extraction demonstrated in test OLEDs, the luminance and current efficiency of OLEDs with the corrugated Ag0.909Al0.091 alloy cathodes were found to have increased by 25% and 21%, respectively. Furthermore, OLEDs with and without corrugations had almost the same electroluminescent spectra.

The researchers concluded their article with the comment that “From the above experimental results, we can confirm that the EL performance of OLEDs can be effectively increased by introducing periodic corrugations, and the improvements arise from the out-coupling of SPP mode which is excited at the desired light-emitting wavelength by the corrugated Ag-Al alloy electrode with an appropriate composition molar ratio.” – Arthur Berman

Jilin University, Yan-Gang Bi, [email protected]