It has come and gone again. Display Week 2021 is in the books, although I continue to pick up a few talks here and there since they are all online for another few months. What follows is only a sampling of the innovations and news that I took away from SID. There is just so much I cannot possibly cover it all here! Here are the talking points you can use as water cooler talk as you get back to normal office work soon.

Nanosys continues to innovate (and acquire)

Nanosys (as usual) saved some of their best press for SID Display Week. They continued to promote a “new green” Quantum Dot (QD) that has higher absorption, and impressive optical characteristics with no heavy metals. This could be helpful in situations where there is limited thickness to work with and one wants to convert as much blue light as possible to green with minimal bleed-through. We have heard about this new material before, and to be honest I was hoping to hear more about its composition. But alas, no word from Nanosys on that front.

They also promoted their new “aerobically stable” QDs in an extruded film called X-QDEF. In theory, these films could be used as diffuser plates instead of an additional film. I have my reservations about the cost of the QDs that go into this design, and if it will actually have a material benefit over the existing QD film implementation. Only time will tell.

Finally, the big announcement from Nanosys this year was their acquisition of microLED company, gl?. The move comes at a time when microLED technology is still in it’s infancy, with massive market potential if it pans out. Nanosys is gambling (hoping) that microLED+QD will be one of the first microLED products to market, and by acquiring gl?, they have laid out a clear path ahead for doing so. There may be other reasons, such as IP portfolio, that a company like Nanosys would want to acquire gl?. One only needs to look at how successful UDC has been in the OLED space with a model of licensing + material sales. If Nanosys can lock down IP related to microLED+QD color conversion, it puts them in a strong position for future license revenue.

MicroLED with QD color conversion

There was no shortage of information on microLEDs this year. I’ll highlight two topics that really stuck out to me as unique in the world of microLED + QD. As you may know, a down-conversion approach would simplify the manufacturing and driving of a microLED display where only one color LED is required instead of three.

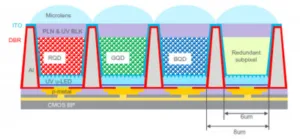

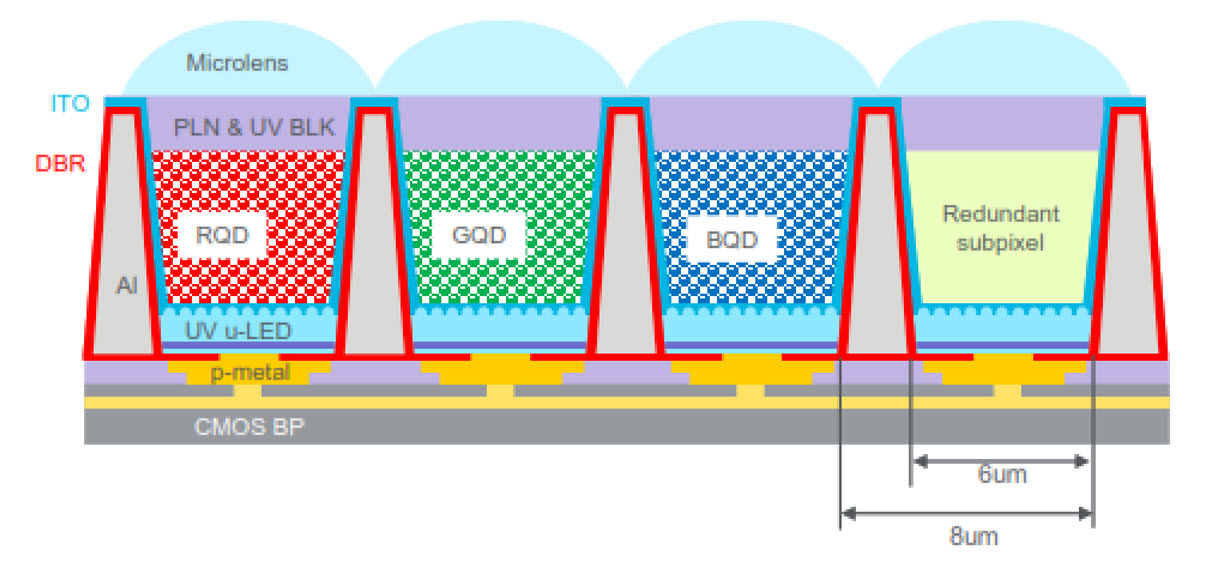

First, Applied Materials presented a new concept for using a UV microLED with R/G/B QD down-converters. This is a major shift from the traditional idea of using blue microLEDs with only R/G QDs. Included in the design are a UV blocking layer to prevent UV transmission, and a DBR (Distributed Bragg Reflector) covering the tapered walls of each pixel instead of black matrix that most designs use. This will presumably help reflect the photons hitting the walls of the device upwards, improving efficiency. There will be a significant penalty in Stokes loss from UV to red (almost 40%), but since current red microLEDs are quite low, perhaps this approach is still viable.

Applied Materials’ design for a UV-microLED. Source: Applied Materials, SID 2021

Applied Materials’ design for a UV-microLED. Source: Applied Materials, SID 2021

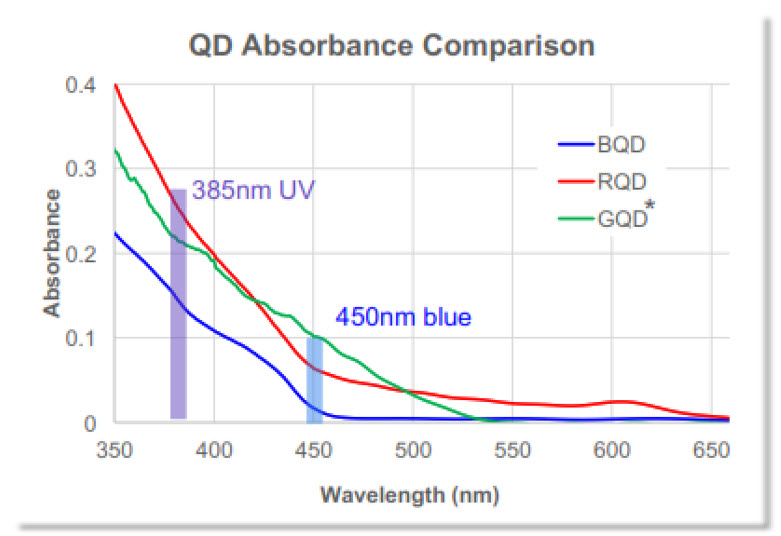

In theory, this approach should help alleviate some of the challenges with absorption that QDs continue to run into since the QDs will absorb more UV light than blue light. As you can see in the graphic below, at 385 nm the absorbance of QDs is much higher than it is at 450 nm. Also, if any UV light does bleed through, it won’t have an impact on gamut since it is not visible (although I’m guessing safety-wise this is undesirable – hence the “UV BLK” layer in the graphic above).

Absorption curves of different QD colors. Source: Applied Materials, SID 2021

Absorption curves of different QD colors. Source: Applied Materials, SID 2021

It’s worth noting that this design requires blue QDs in addition to the standard red and green. And blue QDs are far behind the other colors in terms of peak performance and reliability. Yes, Nanosys and Samsung (and others) have demonstrated devices with ZnTeSe QDs for blue EL-QLED, but I’ll be the first to tell you these devices are a far cry from the performance of their red and green counterparts. Regardless, it appears they were able to make a demo display using this architecture.

Demo Display using UV microLED and R/G/B QD down-conversion. Source: Applied Materials, SID 2021

Demo Display using UV microLED and R/G/B QD down-conversion. Source: Applied Materials, SID 2021

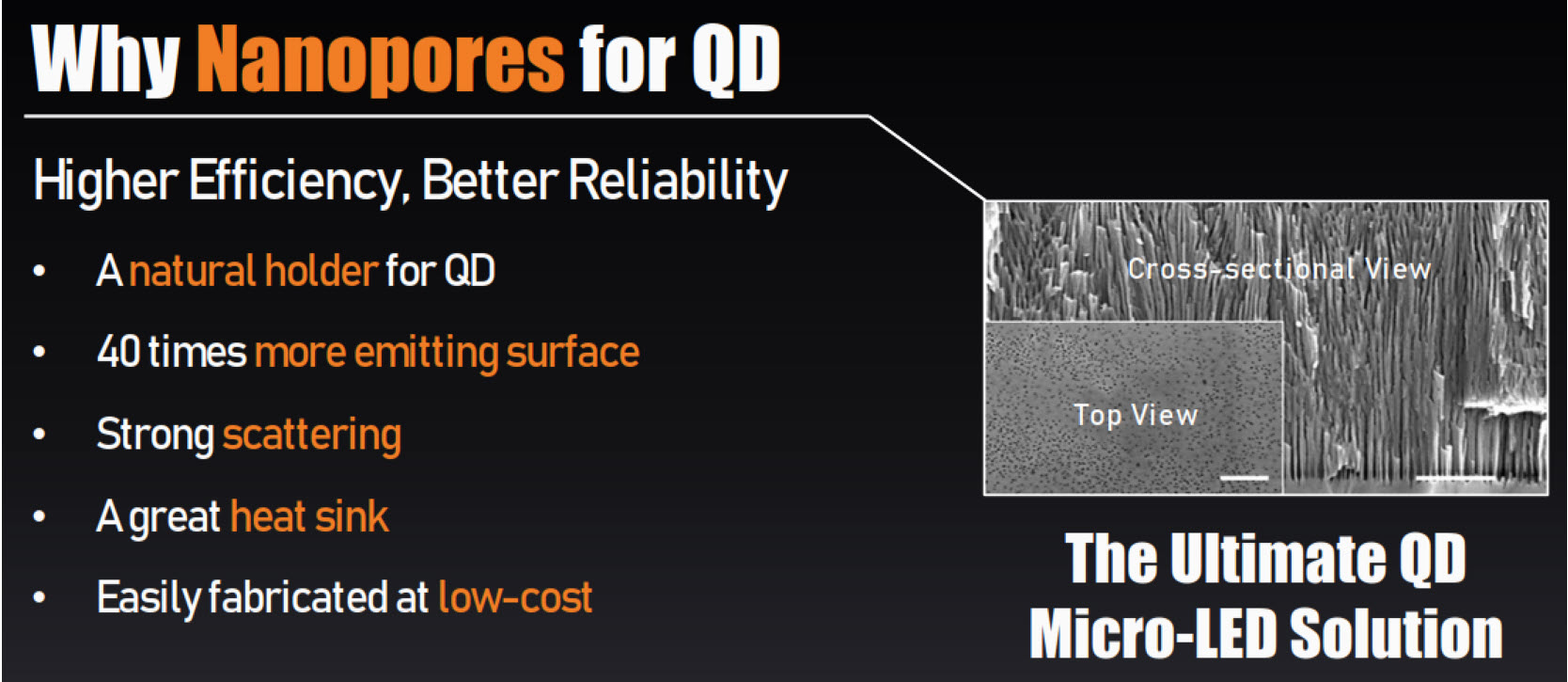

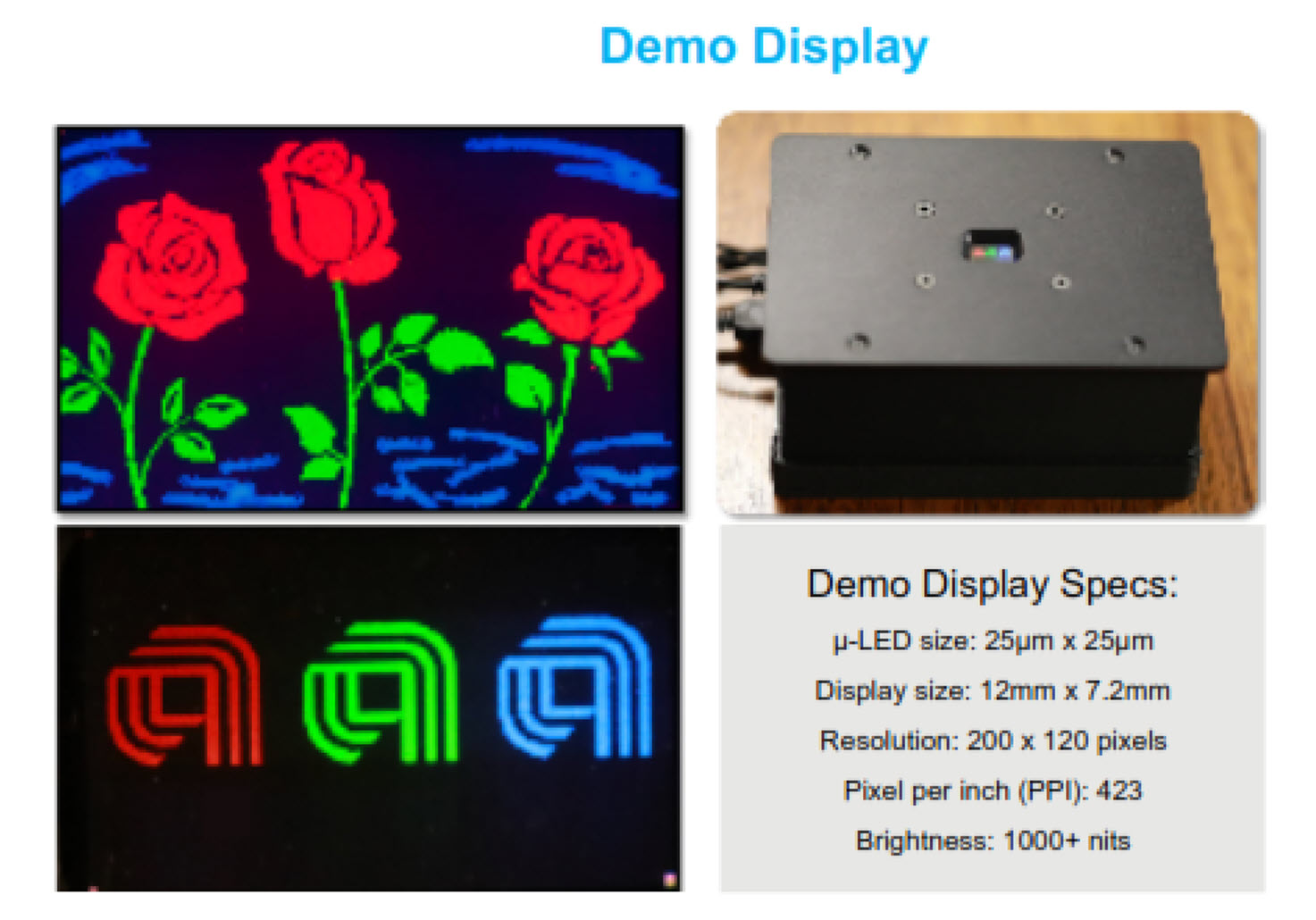

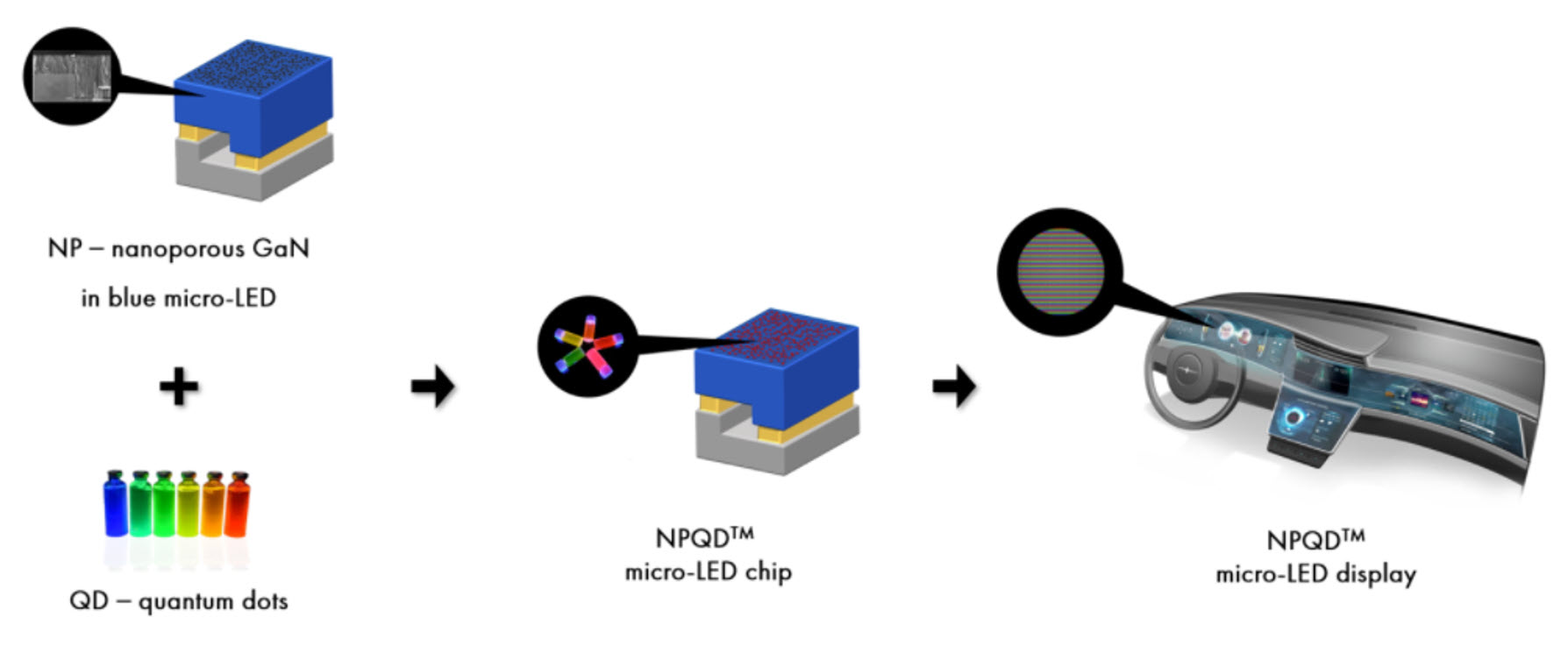

Second, Saphlux shared what might be the first commercially available microLED with QD color conversion. As a newcomer to the QD-microLED game, they bring an interesting technology into play – Nanopores. With a special etching step they are able to make a highly porous structure on top of the GaN which acts as a sponge for QDs and also encourages light recycling (scattering) for improved QD absorbance. This reservoir probably also helps a lot with ink spreading, allowing for easier printing of QDs onto (into?) these microLEDs.

It is my understanding that these microLEDs use Cd-based QDs (based on the peak width described in the technical documents). It remains to be seen if this will be adopted and how it would fare against Cd restrictions. At this point, Saphlux is offering a red-only microLED, and a combination R/G/B microLED, where the blue is native emission and R/G are QD converted. It will be very interesting to see if either of these microLED ideas gain traction.

Integration process for QDs into porous GaN. Source: Saphlux website

Integration process for QDs into porous GaN. Source: Saphlux website

QD/Phosphor – competition or collaboration?

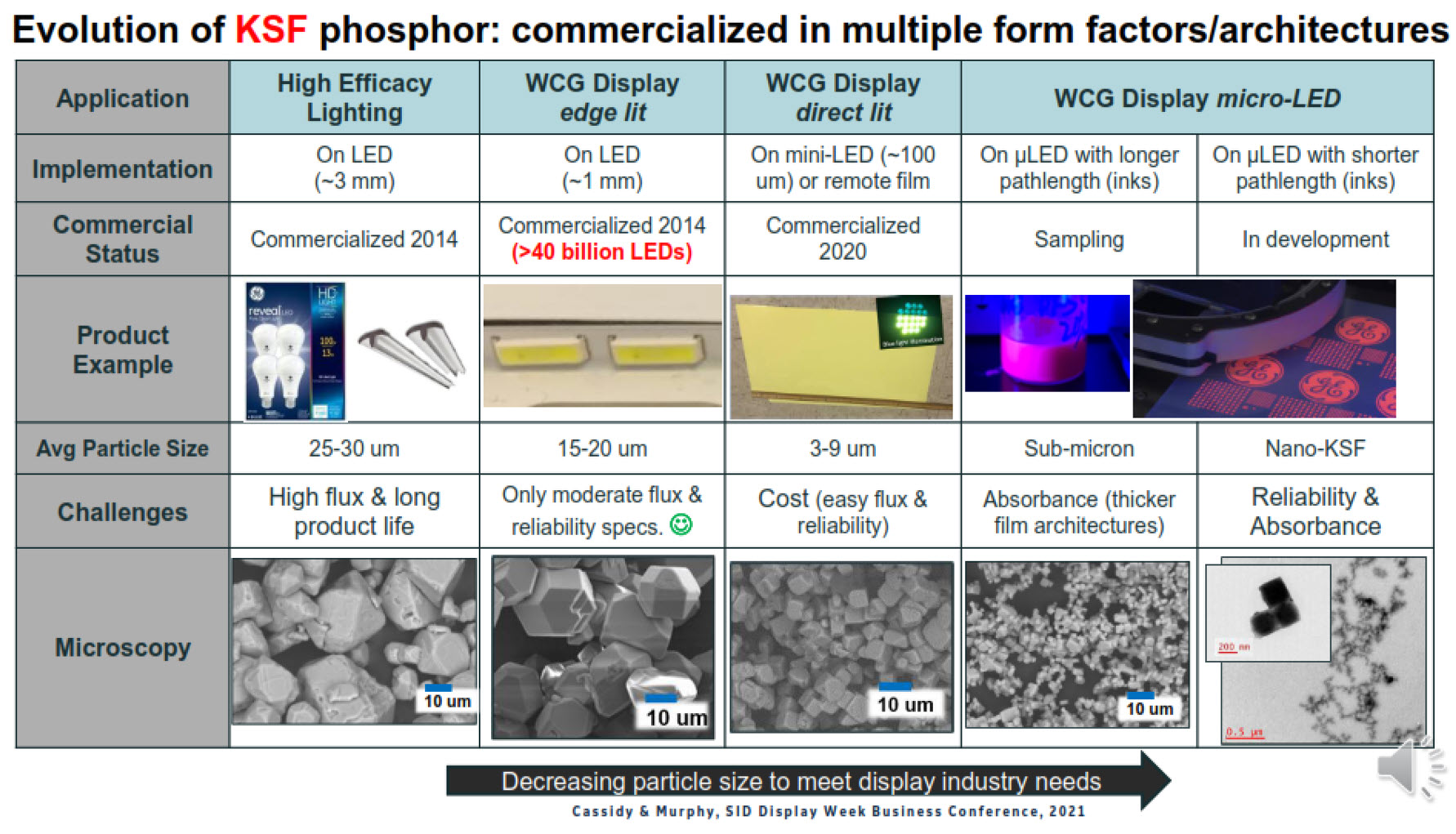

Just as QDs continue to get better and better, so do phosphors. Take for example GE’s widely adopted KSF red phosphor. GE shared an update during the business conference as well as in technical sessions about their progress on both red and green phosphors. In the red category, what impressed me was the development of small sized KSF phosphor, down to <1 micron in some cases. While this is still far larger than QDs, it may open up new opportunities for phosphors if they can be made this small with good performance. Notice the microscopy images in the figure below, showing both sub-micro and nano-sized KSF (which appear to be cubic particles with a size of ~200 nm).

Progressively smaller KSF that has been developed at GE. Source: GE, SID 2021

GE claims their miniaturized KSF phosphor will out-perform QDs in mid-sized microLEDs where the pathlength for color conversion is > 20 nm. In this regime (and at high loading) KSF has a distinct advantage as it does not “self-absorb” like InP does. Self-absorption occurs when there is an overlap in the absorption and emission spectrum of a material, causing emitted photons to be re-absorbed by the material, leading to efficiency losses, especially at high optical density. And before you ask, yes it looks like Nanosys’ new green QDs also have some amount of self-absorption.

GE’s take on efficiency vs thickness for highly loaded QD and KSF films. Source: GE, SID 2021

GE’s take on efficiency vs thickness for highly loaded QD and KSF films. Source: GE, SID 2021

There were a number of mentions, examples, and models that leveraged KSF phosphor along with perovskite green QDs. This pairing appears to make a lot of sense for companies looking to get the highest possible gamut/brightness, so long as they are OK with lead-containing QD films (presumable RoHS compliant though). I noticed two different architectures in which KSF and perovskite could work in harmony. In one case a “Magenta LED” is used (Blue + KSF) along with a perovskite green film. In another architecture KSF and perovskite are mixed (or layered) in a film product. At this point, I don’t see how these architectures would be treated any differently than a QDEF film with InP (except for the lead issue). Price might be a factor in the adoption of this sort of architecture, and it has only been very recently that films containing perovskites have shown the reliability necessary to be implemented in commercial displays. And I am still waiting to hear about one that is widely available for purchase.

There is so much more rattling through my brain after sifting through a week of talks. I will digest it into additional articles later this summer. Let me know if there are topics you want me to write about! (PP)

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.