Quantum Dots on chip (LED chip that is) is a technology that I’ve written about before, in 2018 and 2017. For those of you not familiar with this approach, it’s basically akin to replacing the phosphor in traditional down-converted LEDs (Blue + phosphor = white). Sounds simple, right?

Historically speaking, this has been difficult for QDs to withstand for the following reasons:

- QDs don’t like high temperature environments (LEDs often operate near 100°C).

- QDs don’t like exposure to oxygen and moisture, and in this operating case they are exposed to both (silicone encapsulants are not good barriers)

- QDs degrade more rapidly under high intensity light

So no shortage of challenges for those of us engineering better QD systems!

The display and lighting communities would love to have this technology because it offers the following benefits:

- Narrow emission = wide color gamut and enhanced brightness (displays)

- Improved CRI/efficacy (lighting)

- Simple implementation into existing LED mfg (if dispersed in silicone encapsulant)

- Low QD usage

QDs on chip are here… for lighting

The commercialization of the first on-chip QD product is actually old news by now. It was originally commercialized by Lumileds (providing the LED package) and Pacific Light Technology (providing the QDs) in 2018. In a surprise move soon after, PLT was acquired by Osram. Now Osram is promoting their Osconiq S LED line which contains red CdSe quantum dot technology.

A quantum dot containing powder used for QDs on chip and….

A quantum dot containing powder used for QDs on chip and….

… the Osconic S3030 LED package offered by Osram. I’ll never get sick of seeing those fluorescent QD colors!

… the Osconic S3030 LED package offered by Osram. I’ll never get sick of seeing those fluorescent QD colors!

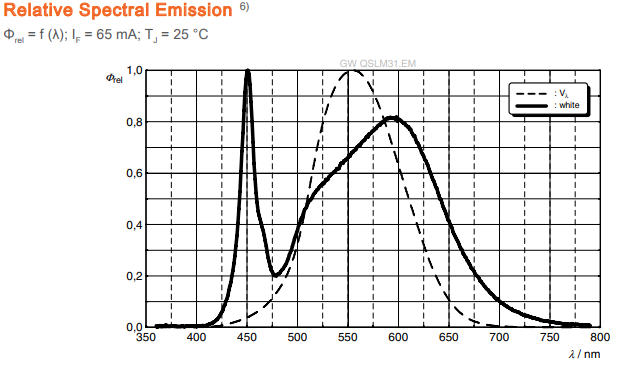

A quick look at the technical data sheet for the Osram Osconic S3030 shows, at minimum, two distinct peaks beyond the obvious blue LED peak at 450 nm. The combination of phosphor and QD provide improved CRI and efficacy over phosphor alone. It’s worth noting that even though these QDs contain Cd, they are used at a low enough level that the product still meets RoHS requirements. On the data sheet it explicitly says “EU RoHS and China RoHS compliant” which means the Cd content is < 100 ppm in the silicone encapsulant material.

Optical spectrum of a red QD + phosphor driven by blue LED (from osconiq s3030 data sheet).

Optical spectrum of a red QD + phosphor driven by blue LED (from osconiq s3030 data sheet).

In addition to keeping the Cd concentration <100 ppm, it’s worth mentioning that the low QD loading may have been necessary to achieve adequate reliability for commercial launch. With more phosphor, the QDs are effectively “screened” and see less blue light flux than if there were QDs alone or higher ration of QD/phosphor. This filtering of light before it hits the QDs could be a fortunate advantage of this approach that may not be suitable for all applications.

What about Displays?

So what does this mean for displays? If Osram has commercialized a product containing QDs for general lighting, doesn’t that mean it will make its way to displays soon? No so fast…

Just because this product has beaten the odds and proven it is reliable enough for general lighting does not mean it will be an easy segue into displays. There are a handful of reasons that we have yet to see this approach implemented in an LCD.

Red only: For starters, the only color QD being used in the Osram case is red. Displays will likely need to have green and red QDs on a blue LED to make a worthwhile value proposition. And since Osram (and for that matter any other company) has yet to commercialize a green QD on chip, one can guess that it’s probably harder than it might seem. There have been a few start-up companies and academics reporting of stable green QDs on LEDs, but I have not seen any of these technologies really take off yet.

QD (Cd) loading: The Osram product is RoHS compliant meaning <100 ppm Cd. But this doesn’t mean that all QD on chip products will be. An LED with a narrow red and green QD together would be the ideal case for displays. Would a product containing R+G QDs remain <100 ppm for RoHS compliance? I suspect it would exceed RoHS limits as the green QD loading required to reach an appropriate white point would be quite high relative to the red QDs. This is mainly due to the low absorption coefficient at 450 nm for green QDs compared to red. LED packages for displays are very different from general lighting though, so it is reasonable to expect that the QD loading requirements could change considerably (up or down).

Competition: And let’s not forget about competition. Both phosphor and QD technology continue to improve at an impressive rate. Future QD implementations like QD color filters may make the technology of QD on chip obsolete in displays. There is already competition on chip from GE’s narrow red phosphor KSF/PFS. With its complicated optical spectrum, it’s not easy to assign a peak width to KSF/PFS, but I have been told it’s equivalent to a 30-35 nm gaussian. While this is better than what InP QDs can do today (the best InP QDs demonstrate 35-40 nm peak width), KSF/PFS is still not as good as Cd-based QDs which can reach 20-25 nm peak widths. Pretty much all other commercial phosphors don’t even come close to the narrow peaks that QDs can offer.

Cd-free: What about Cd-free you ask? InP technology is even more sensitive to atmosphere and temperature than Cd-based QDs, so I expect there is still a long way to go before we see InP on chip. The tricks used to make CdSe QDs stable on an LED may not be as effective with InP.

Here… but not there yet

QDs on chip have hit the market for general lighting, but they still have many challenges remaining before they can have an impact on the display market. Don’t worry though, when they do make it, I’ll be the first to let you know about it.

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.