Protec Carrier Systems GmbH of Siegen, Germany put out a press release about its electrostatic chuck technology which can be used for MicroLED carriage and placing, so we contacted the firm and had a brief telephone interview with CEO, Sebastien Wagner.

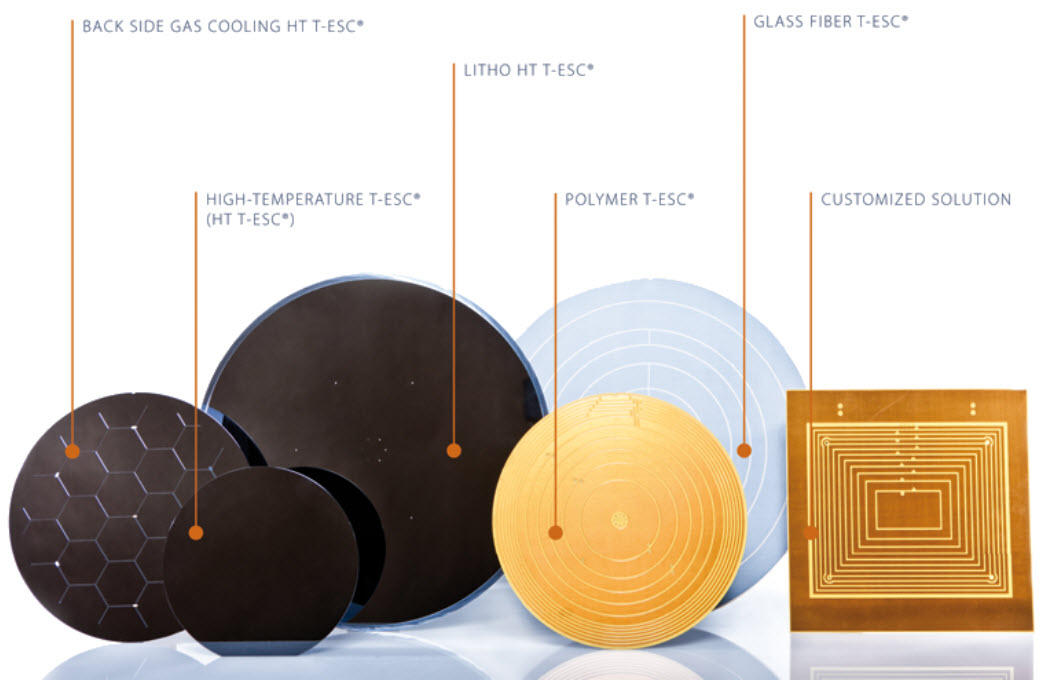

The company has been making electrostatic chucks for the semiconductor industry for around 20 years and the machines are designed to use electrostatic forces to lift semiconductors from the wafers or other sufaces. They can also be used to help with the handling of substrates during processing. The technology is especially suitable for flexible substrates, but can also be used in coating, high temperature and plasma processes. As well as the chucks, the company can supply measurement controllers to supply high voltages.

A feature of the firm’s design is that they don’t need a constant power supply and are based on silicon and polymers, Wagner told us. They are available in a range of sizes from 4″ to 12″ in accordance with Semi standards.

The chucks that the firm has been working on for microLEDs are quite similar and can be used to take LEDs from wafers or from other places. They can be designed to pick up devices ‘line by line’ or in any other configuration. This may be important for microLED, as Wagner believes that the variability of LEDs will mean that it may be impractical to simply take devices from a wafer en masse and place them without testing and some level of sorting or selection. That would mean a two or more stage handling process, from the original wafer, to a test site and then to the final product.

The chucks that the firm has been working on for microLEDs are quite similar and can be used to take LEDs from wafers or from other places. They can be designed to pick up devices ‘line by line’ or in any other configuration. This may be important for microLED, as Wagner believes that the variability of LEDs will mean that it may be impractical to simply take devices from a wafer en masse and place them without testing and some level of sorting or selection. That would mean a two or more stage handling process, from the original wafer, to a test site and then to the final product.

The smallest size device that the company can handle is around 10μ square and it can handle up to around 700K per wafer. It could then place them in different configurations, although the company has not made any announcement yet on the reliability that it can achieve. However, the company believes that this is around four times faster than other companies.

The speed to commercialistion would depend on clients, but there is still a lot to understand in developing microLED and Wagner told us that the bonding, in particular, is looking very critical. He estimated that getting into production could take ‘a few months’.

Sebastien Wagner of Protec