A team of researchers headed by Jongchan Park at the Korea Advanced Institute of Science and Technology (KAIST) (Daejeon, Republic of Korea) is developing a physically thin display that can project video rate multi-colored holographic imagery.

First, a few words of background information.

It is a challenge for the current generation of holographic displays to produce quality 3D imagery having full motion parallax in a compact device. Other limitations include the 3D imagery having a physically small size and a restricted viewing angle. One source of these problems relates to practical limitations on wavefront modulation. In their recent studies, the researchers focused on developing means to address these issues.

A recent article on this topic is entitled “Ultrathin wide-angle large-area digital 3D holographic display using a non-periodic photon sieve.” It was published on March 21st in the on-line edition of Nature Communications volume 10, Article number: 1304 (2019). A copy of the article is available here.

The means investigated by the researchers was based on the use of a so-called photon sieve. In the context of their work, a photon sieve is a thin film of titanium populated with randomly oriented pinholes. The film is 300 nanometers thick and is attached to the back of a LCD. The off-the-shelf LCD used in this work had a diagonal of 1.8 inches and a resolution of 1024 x 768. The number of pinholes in the photon sieve is the same as the number of pixels in the LCD.

Also in the context of their work, random orientation means that the probability distribution of the lateral displacement of the pinhole position from the center position of the LCD pixel is a continuous uniform distribution. The purpose of the non-periodic photon sieve was to increase the diffraction angles of light transmitted through the display device. In addition, the one-to-one correspondence between pixels and pinholes allows independent modulation of the optical field transmitted by each pinhole.

In their article, the researchers point out an important feature of the random orientations of the pinholes in the photon sieve: that the positions and shapes of the pinholes are completely known and do not change over time. Due to this, light transmission through the LCD and the photon sieve occur in a deterministic manner. In addition, since each pinhole is located within the area of each corresponding LCD pixel, the proposed method requires less complex and time-consuming calibration and calculation than required with other holographic approaches.

The researchers go on to explain the fact that the pinholes are randomly oriented also serves to suppress the duplication of the holographic images, an undesirable artifact. They also had to confess that the desirable ability to control (widen) the diffraction angle with pinhole size comes at the expense of increased background noise.

The researchers make special note of the fact that their methodology is fundamentally different from previously reported photon sieve based optical holograms. Paraphrasing their article, the reason is that previous methods tailored the sizes and distributions of the pinholes for use in generating static holograms having given design principles. In contrast, in their latest work, the researchers tailor the light field incident on the pinholes to generate dynamic holograms while the lateral positions of the pinholes are random.

The proposed technique enables a thin form factor for the holographic display device. In addition, dynamic color images are rendered using a single modulator without the need for color filters as is the case with some other holographic technologies.

The team demonstrated their approach by producing a holographic video of a tri-colored rotating cube. The images were made by simultaneously illuminating the LCD with parallel light rays from red, green and blue lasers.

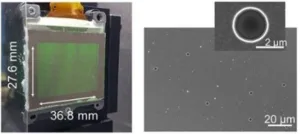

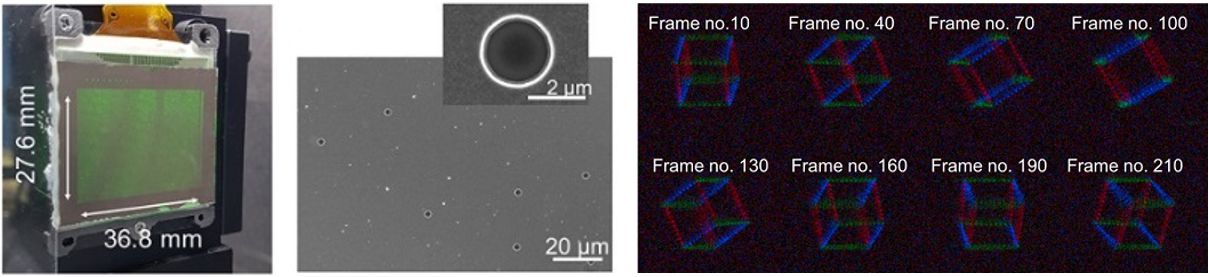

The left hand portion of the figure below is a photograph of the holographic display. The center portion is an electron microscope image of the photon sieve. The images in the right hand portion of the figure were selected from the holographic video of the rotating cube.

Left: The holographic display. Center: An electron microscope image of the photon sieve. Right: Images selected from a holographic video of the rotating cube recorded at 60 Hz utilizing red, green and blue laser light.

Left: The holographic display. Center: An electron microscope image of the photon sieve. Right: Images selected from a holographic video of the rotating cube recorded at 60 Hz utilizing red, green and blue laser light.

The prototype system also served to demonstrate some of the problems with the proposed approach. Because the active area of the LCD pixels is limited to the 2.2??m size of the pinholes, the photon sieves approach suffers from low light efficiency. In the prototype, the light transmittance through the photon sieve was measured as only 0.16%.

In their article, the researchers propose means that have the potential to mitigate these and other identified problems. In the prototype, low transmission was addressed by the use of photon sieves that had either larger pinholes or a greater number of pinholes. Unfortunately, the calculation burden increases linearly with the number of pinholes.

In the conclusion of their article, the researchers state that they have “presented a proof-of-concept for a flat-panel wavefront modulator to generate large-size wide-viewing-angle dynamic 3D holographic images.” They go on to claim that their “technique can be easily integrated into the current LCD production process and is a promising approach towards thin holographic displays.” -Arthur Berman

KAIST, Jongchan Park, 01-217-305-5305, [email protected]