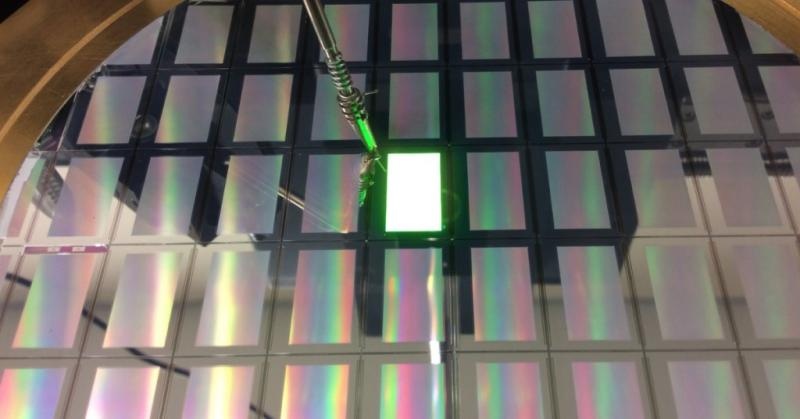

Plessey, an embedded technologies developer at the forefront of microLED technology for the AR and display markets, has developed their proprietary 2D planar gallium nitride on silicon (GaN-on-Si) process to emit Green light without the need for colour conversion techniques.

To produce Green light, LED manufacturers typically apply phosphors or quantum dot conversion materials to native Blue LEDs. These materials then convert short wavelength, typically 450nm, Blue light to Red or Green wavelengths with typically 10% to 30% efficiency.

Plessey’s native Green LEDs are formed inherently using its proprietary GaN-on-Si epitaxial growth process similar to the native Blue LEDs with the principal difference coming in the amount of indium that is incorporated in the quantum well structures of the LED. With no colour conversion losses, the native Green emission is orders of magnitude times brighter than colour converted process for microLEDs. With a dominant Green wavelength of 530nm and a full width half maximum wavelength of 31nm the Green is well suited for colour displays. Additionally, the Green emission exhibits outstanding wavelength stability versus current density.

“Plessey already provides powerful, efficient native Blue microLEDs and through this innovation in our growth technology, Plessey has produced world leading high performance native green micro LEDs which will provide for next generation display and illuminator devices for our customers.” said Mike Snaith, Chief Operating Officer at Plessey.

Plessey’s Green native GaN delivers higher luminance than standard Blue device with Green colour conversion techniques. Plessey’s new manufacturing method for Green coloured LEDs delivers world leading light output for microLED displays.

About Plessey

Plessey is an award-winning provider of full-field emissive microLED displays that combine very high-density RGB pixel arrays with high-performance CMOS backplanes to produce very high-brightness, low-power and high-frame-rate image sources for head-mounted displays (HMDs), and augmented reality (AR) and virtual reality (VR) systems. Plessey operates leading-edge 150mm and 200mm wafer processing facilities to undertake design, test and assembly of LED products, and a comprehensive suite of photonic characterization and applications laboratories.