The complexity of modern air space management and the ATC systems with which the air traffic control officer (ATCO) must interact influences workload and task performance. On a technical level, general increases in air traffic and the resulting increases in the volume of information that needs to be managed also suggests that if the implementation of these complex systems continues without efforts to streamline, there is a greater potential for problems related to performance and equipment malfunction.

While technological advancement is inevitable, mission-critical environments such as ATC need to take a more cautious approach to introducing new components or methods out of concern for maintaining safe management of the air space. Nevertheless, technological advancements for Area Control Centers (ACCs) and Approach Control Centers (APPs) that allow a more streamlined approach to equipment installation, as well as the HMI (human-machine interface) can have a notable impact on operational efficiency and reliability.

Streamlining the visual environment

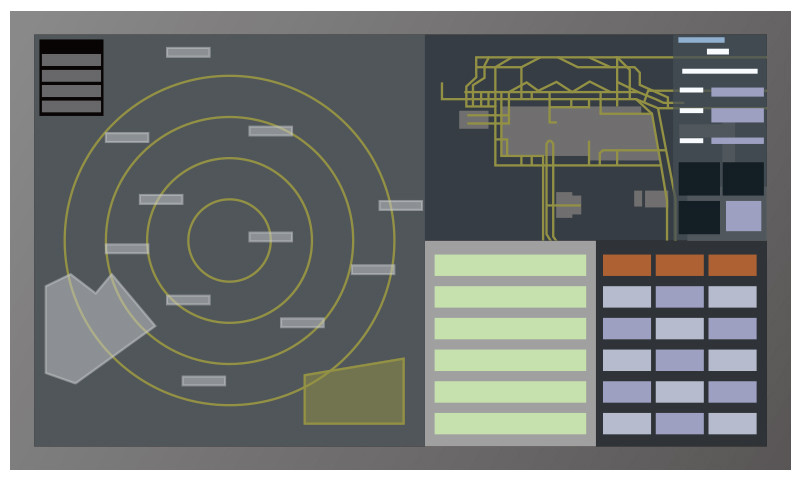

A typical ATM configuration may consist of multiple workstations, monitors, and applications, between which the ATCO needs to frequently shift their view. Modern ATC systems require the ATCO to track a number of variables including radar, weather, flight strips, etc. This leads to concerns over efficiency in managing such a volume of information at a single controller working position (CWP). One way to begin addressing the concerns of juggling many independent visual data sets, is to consolidate multiple monitors and applications into a single screen. Centralizing visual information in this way helps facilitate efficient viewing by minimizing eye movement between applications and providing consistent screen characteristics that work with, rather than against, how the human visual system comprehends information. However, it is not enough to simply gather the information – the ability to manage, distribute, and interact with each application window in accordance with the system requirements and the needs of the ATCO is a crucial component to facilitating a smarter, more streamlined viewing environment.

EIZO has designed and manufactured its own monitors from component level up for over 50 years. This allows for in-house development of unique technologies, such as its Intelligent Display Platform (IDP), developed specifically for the ATC environment. The IDP enables simultaneous display of video signals from up to four independent sources. Traditional Picture-in-Picture (PinP) and Picture-by-Picture (PbyP) functions are limited to a certain number of predefined layouts, providing a relatively inflexible display environment. EIZO IDP-equipped monitors provide complete freedom that allows end users to place each window anywhere on the screen, as well as scale, and layer order priority as required for the task at hand. This flexibility is important to creating an optimized visual experience, as the technical requirements of each Air Navigation Service Provider (ANSP) varies significantly (e.g. air space shape, traffic type, ATM system used, etc.).

Display up to four video sources simultaneously

Freely arrange each source window anywhere on the screen

EIZO’s IDP is a flexible solution with the potential to program new features and functions in accordance with the future needs of the technical ATC environment. In-house development and manufacturing allow EIZO to maintain a modular approach, so the monitor is able to fulfill a role beyond being a passive visual tool, and instead becoming a fully realized solution that addresses the current concerns of mission-critical ATC.

Streamlining installation, maintenance, and the HMI

Using EIZO ATC monitors equipped with the IDP, the ANSP can now display multiple video signal feeds simultaneously. This provides an ergonomically advanced visual environment for the ATCO, as centralizing multiple monitors and applications in one location provides consistent pixel pitch, track and font sizes, color characteristics, etc. – all factors in helping to mitigate controller eye fatigue and contribute to improved situational awareness of their assigned air space.

If the ATCO is using data feeds from multiple sources, then the CWP will also require space for multiple keyboards and mice to manage those different systems. In traditional configurations, a keyboard, video, mouse (KVM) switch has been an essential component to addressing the distribution and management of video signals and control across multiple workstations and monitors in ACCs, APPs, and control towers. A KVM switch is installed between the workstation (input) and monitor (output), to enable centralized control of multiple applications using a single keyboard and mouse. While this system addresses the initial concerns of signal management, there are also technical limitations that still pose many challenges for system integrators and ANSP technical staff.

Cabling and cable management

With any KVM, additional video signal cables, power supply cables (including additional cables for redundant systems), networking cables, etc. are needed just to make the system function. Not only does this complicate the initial installation and add more clutter to the environment, but periodic cable management and lifetime maintenance of the system itself means regular investment in technical support and labor.

Power management

Every time a hardware component is added to a system, there must also be additional power outlets available to supply power to the device. In ATC environments, most components must also have power redundancy options to ensure minimal risk of failure. More devices in a system also result in higher overall power consumption across the facility.

Compatibility issues

For each hardware device in a system, issues of compatibility with other components remains a significant concern for end users. The KVM switch is no exception as it has to interface directly with the workstation and manage multiple signals between connected devices. Any drivers or operating system updates have the potential to generate a compatibility or performance issue in this scenario.

Additional point of failure risk

As with any system, whenever a hardware component is added, it adds another link to an increasingly complex installation. The more connected pieces there are, the more potential points of failure.

EIZO has developed an answer to these concerns with its SwitchLink integrated switching management solution. SwitchLink is integrated directly into the monitor itself which enables seamless switching of keyboard, video, mouse, and dynamic touch input without the need for an external KVM switch. Depending on the required configuration, up to four video signal feeds can be connected to a single monitor, with the option to connect an additional two auxiliary monitors, for an up to six-monitor configuration operated by a single keyboard and mouse.

Having an integrated switching solution not only provides seamless operation for the ATCO, but it addresses the previously mentioned issues concerning excess cabling and compatibility. By eliminating the external KVM from the greater system install, ANSPs and system integrators can effectively reduce the number of cables required, as well associated maintenance. Using a six-workstation CWP as an example, the installation would require two fewer power cables and six fewer video signal cables. Multiplied by the number of CWPs in the ACC or APP means a significant reduction. Furthermore, the monitor and built-in switching component are developed and manufactured by the same engineering team in-house at EIZO to ensure smooth handshaking between internal components and optimum performance throughout the lifetime of the monitor. The result: fewer cables, less maintenance, lower power consumption, and less risk for malfunction or compatibility issues.

Keyboard, video, mouse, and dynamic touch switching

SwitchLink uses standard USB HID class specifications so that any generic keyboard and mouse can be used to operate all signal sources seamlessly without any external switching device required. Signal switching is achieved instantaneously and automatically simply by mousing over the target window.

SwitchLink Mouse

EIZO uses a Mouse Cursor Direct switching method for smooth and seamless operation. Wherever the cursor is located determines the active workstation input. When the cursor is moved from the current active window (e.g. input 1) across the border to another window (e.g. input 2), the monitor recognizes the point of departure from the previously active window to the new active window automatically and switches to the active workstation. The response time when switching mouse input to another workstation is approximately 0 ms for completely smooth operation.

SwitchLink Keyboard

To toggle between workstations, EIZO also implements keyboard hotkey switching. By activating a predefined hotkey, USB control of the keyboard and mouse will switch to another workstation.

SwitchLink Dynamic Touch

A unique feature of SwitchLink is the integration of dynamic touch switching capability. With EIZO’s IDP enabling up to four workstations to be displayed simultaneously on a single monitor, SwitchLink allows each window to have its own independent touch connection with automatic switching built in.

The touch operation works as an HID touch digitizer so it can determine the coordinates of the touch point with complete accuracy. The USB Host controller recognizes the touch coordinates by calculating the values in accordance with the absolute coordinate system. This means that each point on the touch plane is determined by a distance from a reference point and an angle from a reference direction. For example, if the monitor’s resolution is 3840 x 2160 pixels, touch coordinates are expressed as 0-3839 for the x value, and 0-2159 for the y value. When three video sources with resolutions of 1920 x 2160 pixels (input 1), 1920 x 1080 pixels (input 2), and 1920 x 1080 (input 3) are displayed as shown in Figure 1, then the coordinates of the starting point of input 1 is ow1=(0, 0), input 2 is ow2=(1919,0), and input 3 is ow3=(1919,1079). When the user touches the screen at coordinates tm(2400,1920) SwitchLink calculates tm(2400,1920) – ow3(1919,1079) = tm3 (481,841), which determines there was touch input at those coordinates within the input 3 window. Simply put, when touch input is detected, the coordinates of the touch point in reference to the entire screen are calculated internally by SwitchLink and then converted to the coordinates of the designated input window to enable automatic touch switching and operation. Built-in dynamic touch switching is an industry-first development and allows the ATCO to operate the monitor in a way that feels natural and intuitive.

Continuing to pave the way towards intelligent visual systems

IDP and SwitchLink are supported by the already available Raptor RP4325 (42.5-inch, 3840 x 2160) and Raptor RP3225 (31.5-inch, 3840 x 2160) monitors for ATC primary control and tower. With simultaneous display and multiple methods of switching available, ATCOs are able to interact with multiple workstations seamlessly, as if operating one. Further expansion of these technologies is still to come, as EIZO continues to invest in developing more intelligent and reliable solutions to further support more streamlined, modern ATC operations.