Stanford University researchers have developed a new manufacturing process for gallium arsenide – a semiconductor material that is faster than silicon, but around 1,000 times more expensive to work with.

Smartphones already use gallium arsenide, due to its speed. Solar panels are among other applications, thanks to the material’s efficiency, but the expense limits the material’s use.

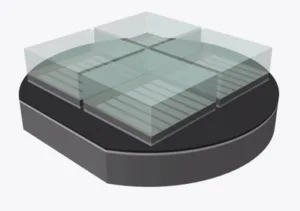

Both silicon and gallium arsenide are fashioned into wafers as part of the process to turn them into electronic devices. The new process aims to lower the cost by reusing the gallium arsenide wafer.

Today, electronic circuits in a gallium arsenide device are grown on top of the wafer.In this scenario, the wafer is only a backing; the layer of circuitry on top contains the electronics. Stanford researchers aim to add steps to the process to reuse the wafer.

First, the wafer was covered with a layer of disposable material. A gallium arsenide circuit layer was then formed on top of the disposable layer, using a standard gas deposition process. A laser was used to vaporise the disposable layer, and the circuitry was lifted off. The circuits were then mounted on a more solid backing, and the wafer cleaned before being used to make a new batch of circuits.

It is estimated that the new process would still be 50 – 100 times more expensive than using silicon, but it still represents a massive cost reduction from today’s processes. Economies of scale – which have, over time, made silicon so cheap – would lower the cost further.

A video detailing the process can be viewed at http://tinyurl.com/qeq9gbg.

Analyst Comment

It’s an old joke that Gallium Arsenide is the future of the chip industry, and always will be! (BR)