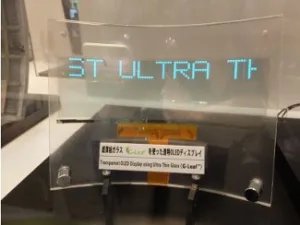

The world’s thinnest glass plate has apparently been developed by Japan’s Nippon Electric Glass (NEG). ‘G-Leaf’ is 30µm thick and can be used as a substrate for flexible displays. NEG demonstrated a flexible OLED that is 90µm thick, sandwiched between two G-Leaf sheets, at Ceatec earlier this month.

G-Leaf’s plates are manufactured using an overflow method. During the process, the temperature at which the glass is manufactured and speed at which it is stretched is varied.

The Nikkei says that, when touched, the G-Leaf glass ‘felt like a plastic film’.

Glass substrates have an advantage over plastic (currently used for flexible displays), as they act as a gas barrier themselves. Plastic substrates require a separate gas-barrier layer, raising costs.

Display Daily Comments

Definition:

The ‘overflow down draw’ method is a way of producing glass for FPDs. A sheet of glass is formed when molten glass flows down the sides of a tapered trough and rejoins at the bottom. Unlike the float glass method, the glass surfaces are not touched by molten tin.