An enabling material for many flexible electronic devices is a flexible, transparent electrically conductive thin film. In order for such a film to be commercially viable, it is necessary that it can be manufactured by a means that is both scalable and low cost. Such a film is being developed by a team led by Alexander Yarin, a Distinguished Professor of Mechanical Engineering at the University of Illinois at Chicago (Chicago, Illinois).

The latest results of the team are reported in an article entitled “Production of Flexible Transparent Conducting Films of Self-Fused Nanowires via One-Step Supersonic Spraying.” It was published in Advanced Functional Materials 2016. A copy of the article is available for purchase on-line and can be found here.

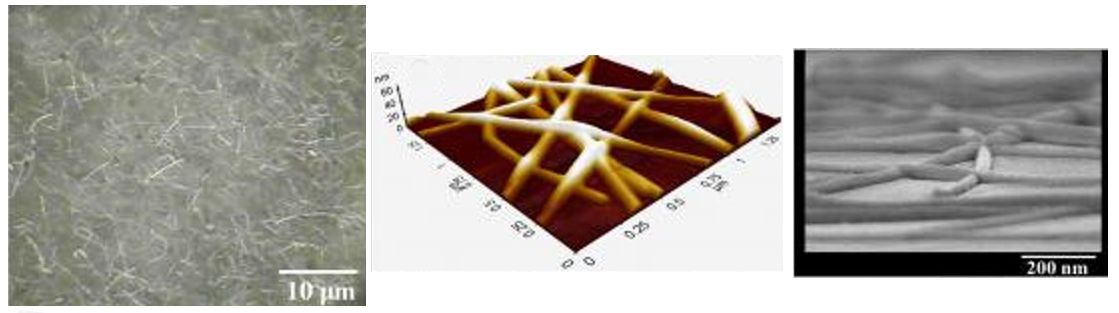

The new film is made of fused silver nanowires. Silver nanowires are particles that, as the name implies, are very long and thin. More specifically, the nanowires typically measure about 20 microns long, but their diameter is a thousand times smaller. This makes the nanowires significantly smaller than the wavelength of visible light and, consequentially, there is minimal light scattering from a film made of such particles.

The films are produced by a process in which the nanowire particles are suspended in water and propelled through the air towards a substrate at supersonic speed. The device used to spray the material is called a de Laval nozzle. The nozzle has the same geometry as a jet engine but is only a few millimeters in diameter. By this means, the liquid is atomized and will evaporate in flight. When the nanowires strike the surface they fuse together, as their kinetic energy is converted to heat. The ideal speed is 400 meters per second. If the speed, and thus the energy, is too high, the wires are cut. If the speed is too low, then there is not enough heat to fuse the wires.

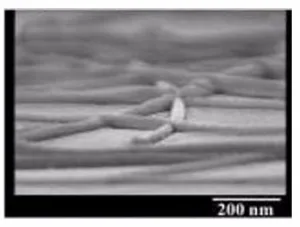

Several microphotographs of such self-sintered silver nanowire films are illustrated in the figures below.

The resulting film has very low electrical conductivity, almost the same as that of a silver plate. The sheet resistance is less than 10 Ω/sq. At the same time, the transmittance of the film is very high at greater than 90%, almost that of glass.

The film is reported as capable of substantively maintaining its electrical and optical properties even after being bent repeatedly and stretched to seven times its original length.

The team reports that a coating can be deposited over a 100 cm² area in about 30 s. In addition, it was proved possible to apply the nanowires to flexible plastic films and to three dimensional objects. The surface shape did not matter.

Since fabrication of the film requires only one step, it lends itself to an industrial scale, continuous roll-to-roll manufacturing process. It follows that the film should be easy and cheap to fabricate.

The team speculates that when fully perfected, the new film technology offers the potential of a wide range of novel applications. Specifically mentioned are roll up touchscreen displays, wearable electronics, flexible solar cells and electronic skin. -Arthur Berman

University of Illinois at Chicago, Alexander Yarin, 312-996-3472, [email protected]