Mirrorcle Technologies demonstrates a MEMS-based Programmable Light Source prototype at CES and in Las Vegas and at the Photonics West exhibition in San Francisco.

A high-power 445-450nm (wavelength) laser beam is programmably directed onto a 10 x 10mm phosphor plate where it creates a very high brightness and luminance image. This image is projected by a projection (condenser) lens in a desired direction within a lens-governed field of regard. The key breakthrough is that by selectively directing the high-power laser by means of the company’s gimbal-less MEMS mirror to desired section of the phosphor, the projected light can be arbitrarily shaped with a high contrast ratio – e.g. it can illuminate only a section of the full field of regard, it can project shapes or symbols or selectively allocate brightness onto dynamically adjustable spots to highlight objects of interest. The outgoing beam is fully programmable in terms of shape, brightness and direction from Mirrorcle’s own software such as MirrorcleDraw, or from customers’ own applications built with Mirrorcle’s SDKs. Enabling this novel lighting approach in a highly compact and efficient way is Mirrorcle’s MEMS mirror technology which allows for fully arbitrary scanning of not only e.g. raster scans across the whole field of regard or selectively in controllable areas within that space, but also enables shaping the outgoing light by means of e.g. vector graphics scanning of shapes, symbols or characters. Ultimately, the mirror is able to direct all of the laser power to a single tiny dot on the phosphor plate and create a very low divergence high brightness light beam into the distance.

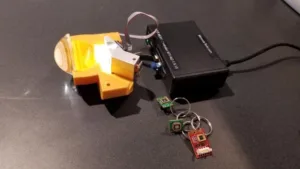

Figure 1. Mirrorcle’s Programmable Light Source (PLS) demonstration at Photonics West 2018. Shown is a standard USB-SL Controller which connects to a scan module with laser and scanning MEMS mirror. Also shown is an opened scanner housing and the outging projection lens.

Transmissive Mode vs. Reflective Mode PLS

Mirrorcle has presented PLS concepts in both reflective and transmissive types since 2015. The 2015 prototypes were put together using off-the-shelf components for laser diode sources and phosphor targets. In transmissive mode, the blue laser light enters from one side, and exits the other side of the phosphor. A transmissive target will fluoresce from both sides of the target, therefore limiting the light that is gathered by the projection lens to output from the module. In reflective mode, the phosphor has a metal backing which re-directs the light all to the same side. This maximizes the light collected by the projection lens, yielding in a brighter output. In subsequent 2018 designs, PLS-02 and PLS-03, Mirrorcle has demonstrated reflective mode systems with brighter outputs, producing >120 lumen white light projector with a 1W laser and reflective phosphor target.

Controllable Laser-Phosphor Projector Suitable for Many Applications

The PLS demo, dubbed PLS-01, is a lower-power version of a new technology for programmable projection of light based on laser-phosphor projection. This technology is geared for a number of industries and application areas including automotive lighting, security and industrial lighting, search lights etc. Bright white light, shaped by the rapid movement of the MEMS mirror, is projected by a condenser lens to a target surface area such as e.g. road or a wall or carpet. The projected light is real-time configurable by Mirrorcle’s standard software suite. It is the result of the unique capability of Mirrorcle MEMS mirrors to run fast scan patterns in both axes and operate safely with high optical laser powers (several Watts) and at elevated temperatures, simulating an automotive headlight environment. Over 100 hours of high power testing has been done with 4W of CW power on the MEMS mirror at room temperature, and at 60°C. These devices have pushed the limits of the laser source, surviving >8W of CW power in multiple hour-long tests.

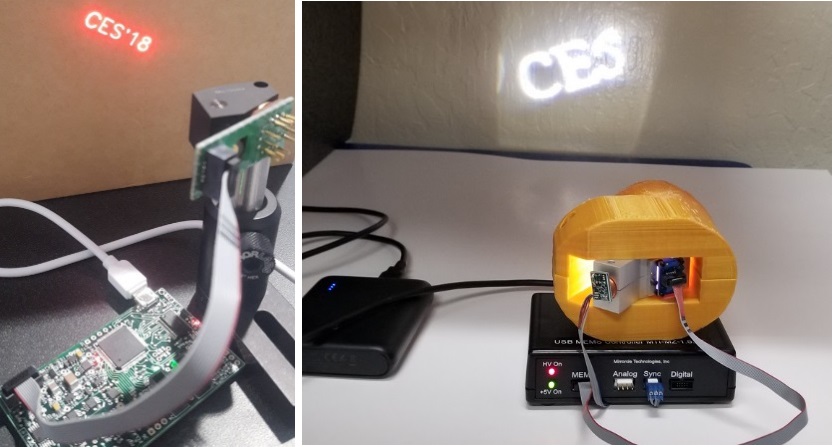

Figure 2. Demos from CES2018 in Las Vegas, NV. (a) a prototype Playzer Scan Module PZEK-01R demonstrates the compact opto-mechanical setup of a MEMS mirror laser and optics with a 40° FoV and the compact USB battery powered OCCIE 1.1 MEMS controller, (b) PLS-01 powered by a USB battery, running from the USB-SL MZ MEMS Controller with flashed content, (c) the PLS-01 with the cover off to show the MEMS mirror scan module, transmissive phosphor target and condenser lens.

About Mirrorcle Technologies, Inc.

Mirrorcle Technologies, Inc. (MTI), founded in 2005, is a California corporation that commercially provides products and services based on its proprietary optical microelectromechanical system (MEMS) technology. Since its founding, and supported by its continuous investment in R&D, MTI has been offering the world’s fastest point-to-point (quasi-static) two-axis beam-steering mirrors, as well as resonating-type micromirror devices with rates up to HD video display. MTI is globally the only provider of tip-tilt MEMS actuators in combination with mirrors from submillimeter to several mm in diameter, offering customers a wide selection of specifications to optimize their paths to successful commercialization.

MTI maintains a laboratory at its headquarters and has year-round, 24-7 access to wafer-based CMOS and MEMS fabrication facilities. MEMS mirror fabrication, wafer-level and die-level testing, packaging and outgoing inspections are all performed in clean-rooms. MTI has an established manufacturing service cooperation with a leading MEMS wafer foundry ensuring streamlined, high-quality volume production.

As a privately held company, MTI is able to act efficiently, offering creative and highly responsive service to customers. The company provides highest-quality products and support to facilitate customers’ product development and successful commercialization. The team draws on several decades of combined experience in MEMS design, fabrication, and testing.